O&M

-

O&M

Leading-Edge Conveyor Technologies Reduce Dust Emissions

Reducing dust from coal conveyors has moved from a housekeeping chore to a safety challenge, especially with Powder River Basin coals. Here’s what you need to know about the latest coal-handling system design.

-

O&M

High-Hazard Coal Ash Sites, and the TVA Spill Revisited

The EPA has identified 44 "high hazard" coal ash ponds around the U.S., and a recent Tennessee Valley Authority report indicates that the agency should have known its Kingston Plant pond would have been one of them.

-

O&M

PRB Coal Users’ Group Educates Industry on the Dangers of Combustible Dust

The annual meeting of the Powder River Basin Coal Users’ Group was held in association with the ELECTRIC POWER conference in early May in Chicago. Get a taste of the festivities, technical meetings, and the announcement of the group’s 2009 Large and Small Plant of the Year winners in this conference report.

-

O&M

The 7,000-Foot Challenge

The Springerville Generating Station in Springerville, Ariz. (Unit 3 was POWER’s 2006 Plant of the Year), uses two lined ponds to hold water collected from its cooling towers. With the construction of Unit 4, the plant’s owner, Salt River Project (SRP), one of Arizona’s largest utilities, wanted to increase the capacity of pumps used to move effluent from one pond to another to avoid the possibility of overflow. SRP engineers wondered if using a vertical turbine pump on a floating barge would improve managing the water levels in the two ponds.

-

O&M

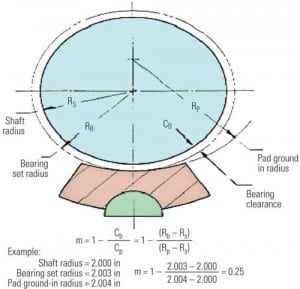

Preventing Turbine Water Damage: TDP-1 Updated

ASME’s latest revision of its Recommended Practices for the Prevention of Water Damage to Steam Turbines Used for Electric Power Generation: Fossil-Fuel Plants, ASME TDP-1-2006, contains much important design and operating advice that is proven to protect steam turbines. However, many in the industry are not as familiar with the update as they should be. This article provides a concise overview of this critical design standard.

-

O&M

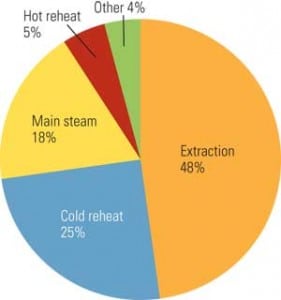

Managing Minimum Load

Reducing the minimum load at which a steam turbine can reliably operate is one way to increase revenue for marginal base-loaded units during periods of low electrical demand. For this reason, it is not unusual to see merchant plants operating at "super minimum" load levels that are well below the typical 25% rated full-load limits. However, such units are operating well outside the original equipment manufacturer (OEM) design basis, and owners may experience undesirable damage to their turbines for a number of reasons. That’s why it is important for owners to understand the trade-offs and risks that come with such operation.

-

O&M

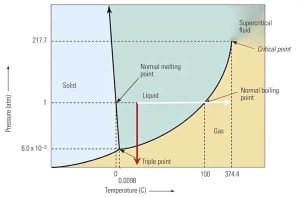

Polymeric Solution for Pump Cavitation

Cavitation is defined as the phenomenon of forming and imploding vapor bubbles in a region where the pressure of the liquid falls below its vapor pressure. Cavitation and the resultant damage can occur in any fluid-handling equipment, especially in pumps. Technological advances in industrial protective coatings and composite repair materials have made it possible to repair pumps operating in a cavitating environment rather than simply replacing them after damage occurs. Cavitation-resistant (CR) elastomers have the ability to retain adhesion under long-term immersion, dissipate energy created under high-intensity cavitation, and provide outstanding resistance to corrosion and other forms of erosion.

-

O&M

Optimize Gas Turbine Performance Using Acoustic Simulation Software

Increasingly fierce competition driven by deregulation and privatization is putting downward pressure on power plant operations and maintenance (O&M) budgets. Recently, lower natural gas prices have pushed natural gas – fired combined-cycle plants higher up in many utilities’ dispatch order in some regions, a welcome change from the twice-a-day cycling experienced by some plants during the past few years. However, with more operating hours comes more interest in plant operating availability, and that means increased emphasis on reliable gas turbine operation.

-

O&M

Extreme Oil Changes

Performing regular oil changes on remote generators is far from simple or cost-effective. Here’s how one firm harnessed technology to extend oil change intervals from one week to two months.

-

O&M

Improved Filler Metal Enables Higher-Temperature Dissimilar Metal Welds

The welding of dissimilar metal joints in new and retrofit power plant boiler tubing has long proved challenging. New plants designed to operate at higher temperatures and pressures require advanced alloys and a filler metal that produces reliable welds. EPRI recently developed and sponsored the commercialization of a new filler metal. Its first application is the fabrication of boiler tubes for American Electric Power’s ultrasupercritical John J. Turk, Jr. Power Plant.

-

O&M

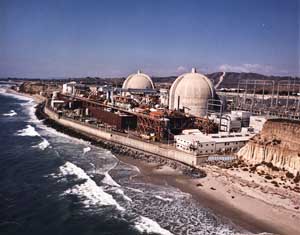

Steam Turbines: San Onofre Nuclear Generating Station Gets Upgraded Generator Rotors

Southern California Edison’s (SCE) 2,250-MWe San Onofre Nuclear Generating Station (SONGS) recently took receipt of a new and upgraded generator rotor for one of its two Alstom steam turbine generator units (Figure 1). Following the successful installation and flawless start-up of this new rotor in the Unit 2 generator, the former Unit 2 rotor was […]

-

Legal & Regulatory

Looking Downstream After the Cooling Water Case

In the wake of the recent U.S. Supreme Court ruling related to cooling water intake practices at large power plants, many utilities are relieved to be off the hook as far as implementing expensive control upgrades to protect fish and other aquatic organisms.

-

O&M

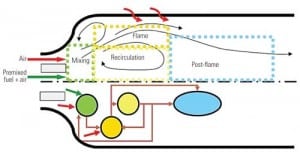

Advanced Modeling Tools Slash Combustor Analysis Chores

Combustor design simulation requires the resolution of complex geometry, turbulent flow patterns, heat transfer, and detailed chemistry. Although computational fluid dynamics (CFD) can simulate the reacting flow in realistic geometries, it requires the use of severely restricted chemistry models that are too simple to accurately simulate emissions and operational stability. A new simulation tool is now available that eliminates this CFD shortcoming while significantly reducing computing time.

-

O&M

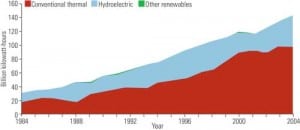

Turkey Opens Electricity Markets as Demand Grows

Turkey’s growing power market has attracted investors and project developers for over a decade, yet their plans have been dashed by unexpected political or financial crises or, worse, obstructed by a lengthy bureaucratic approval process. Now, with a more transparent retail electricity market, government regulators and investors are bullish on Turkey. Is Turkey ready to turn the power on?

-

O&M

Focus on Organics in Steam

Organic compounds can enter the steam cycle from a number of sources, including water treatment chemicals, or as part of a manufacturing process. Regardless of the source of the organics, their effects range from fouling polisher resins to causing significant steam turbine damage. Conventional water pretreatment systems are available to remove organics from water, but removing organic compounds at their source is the best place to start addressing the problem.

-

O&M

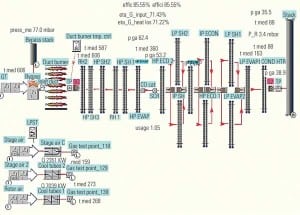

Computer Simulation of HRSGs Can Improve O&M

Obtaining accurate data about the performance of a plant’s heat-recovery steam generator is crucial to ensuring the smooth operation and maintenance of the equipment. Software designed to model and simulate HRSG operations can provide valuable information about corrosion and other operational problems.

-

O&M

Solving Fouling Problems with an HRSG Upgrade

Despite being located on the beautiful Hawaiian island of Oahu, the Kalaeloa Cogeneration Plant had trouble in paradise: Large amounts of ash from #6 low-sulfur fuel oil coated the finned tubes of its heat-recovery steam generators (HRSGs). The fouling added an extra $5 million dollars a year to the plant’s fuel bill. By retrofitting the HRSG with new panels and improved fin design, the plant overcame the fouling problems, stopped tube leaks, and cut fuel costs.

-

O&M

Nuclear: Realistic Simulation Assists in Nuclear Power Plant Certification

From the onset of the civilian nuclear era (marked by President Dwight Eisenhower’s "Atoms for Peace" speech to the United Nations in 1953), there has been a strong awareness of the importance of safety within the nuclear energy industry. Western experts have devoted much time and effort to ensuring the integrity of reactor cores and […]

-

O&M

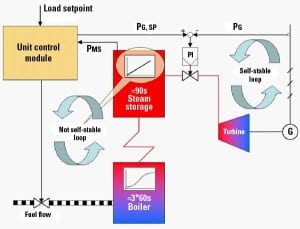

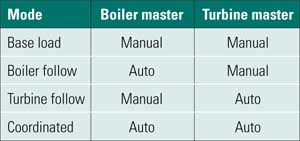

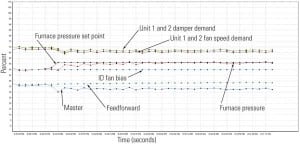

A New Era in Power Plant Control Performance

Recent improvements in the performance of steam power plants have been achieved with advanced computerized controls. These new control schemes not only reduce fuel consumption and make the plant much more responsive, but they also can significantly decrease start-up commissioning time and cost.

-

O&M

Better Combustion Airflow Monitoring at the Hunan Yiyang Power Plant

Measuring combustion airflow in a coal-fired power plant can be problematic when using annubar instruments that feature small holes that can easily plug with coal dust. Sierra Instruments eliminates this big maintenance headache with its more-accurate, nonplugging thermal mass flow meter design.

-

O&M

Lessons Learned from a Hydrogen Explosion

On January 8, 2007, a hydrogen explosion at the Muskingum River Power Plant’s 585-MW coal-fired supercritical Unit 5 caused one fatality, injuries to 10 other people, and significant damage to several buildings. The explosion occurred during a routine delivery of hydrogen when a hydrogen relief device failed, which allowed the contents of the hydrogen tank to escape and be ignited by an unknown source. This article covers the findings of the incident investigation and the actions the plant has taken to prevent a reoccurrence.

-

O&M

Boiler-Tuning Basics, Part II

Boilers have enormous thermal mass and are relatively slow to react. Turbines are nimble and quickly answer an operator’s command. Coordinating an entire plant requires an intimate knowledge of both systems and selecting the right logic tools to bring them together.

-

O&M

Hydrokinetic Plant Piggybacks on Existing Hydro Plant

Hydrokinetic energy — which generates power by using underwater turbines that harness moving water — is on the rise in the U.S. In January, the first U.S.-licensed, commercial, grid-connected hydrokinetic project installed the first of two 100-kW nameplate-rated turbines downriver from an existing run-of-river hydroelectric plant on the Mississippi River.

-

O&M

Fire Safety in Modern Hydroelectric Stations

It may seem counterintuitive, but fire can be a serious danger in hydropower plants. In some respects, the danger is even greater than in thermal power stations. Most U.S. hydro plants are 30 to 70 years old but can deliver another 20 or 30 years of service with upgrades — including state-of-the-art fire protection systems. The design options outlined here also apply in large part to other generating stations.

-

O&M

Making the Most of Thermal Imaging Data

This article discusses planning, operation, and documentation procedures designed to effectively use the thermal imaging camera as a critical element in an effective reliability program.

-

O&M

Reducing Millirem Exposure

Radioactive materials are clinging to the inside walls of reactor system components because of a noble metals injection process error some years ago at Cooper Nuclear Station (CNS). CNS has launched an aggressive, long-term program to remove the materials, but until the work is successfully completed, the station is also taking extensive measures to protect employees and reduce higher source term dose.

-

O&M

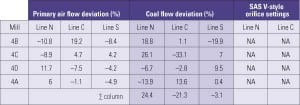

Balanced Pipe Fuel Flow Is Not Enough for Uniform Combustion

Conventional wisdom tells us that the key to good boiler combustion requires carefully balancing the fuel-air ratios across all the coal pipes. Recent tests show that the uniformity of the burner-to-burner stoichiometries—not balanced pipe-to-pipe fuel flow distributions—dictates combustion uniformity.

-

O&M

Dominion Solves Mt. Storm’s Fuel-Handling Problems with Improved Coal Silo Design

Many coal-fired power stations built before 1980 were designed for handling relatively easy-handling lump coal. If your plant’s bins, bunkers, and silos aren’t up to dealing with today’s range of more variable coal properties, this case study shows one way to minimize coal flow problems.

-

O&M

Boiler-Tuning Basics, Part I

Tuning power plant controls takes nerves of steel and an intimate knowledge of plant systems gained only by experience. Tuning controls also requires equal parts art and science, which probably is why there are so few tuning experts in the power industry. In Part I of a two-part series, we explore a mix of the theoretical and practical aspects of tuning boiler controls.

-

O&M

"Blueprint" Your Pulverizer for Improved Performance

Pulverizer throughput is determined by the coal fineness desired for a given coal. However, compromising on coal fineness when your pulverizer isn’t up to snuff can increase NO x and cause many furnace problems. Your least costly option for increasing pulverizer capacity is to pay careful attention to key dimensions and critical tolerances during your next overhaul.