ELECTRIC POWER 2008 offers access to the latest products and services

Innoveyor™ Inc. offers titanium-enriched polyvinylchloride (PVC) idler rolls, which are heavy-duty, lightweight rolls, branded YeloRoll® due to their color. The t-PVC-based YeloRoll exceeds CEMA D standards. In snow and ice, YeloRoll prevents buildup that will damage the belt, slow productivity, and eventually bring production to a halt. Its smooth, nonporous surface rejects the graining and abrasion of steel can rolls. YeloRoll also won’t rust or corrode. It maintains a smooth, nonstick surface that prevents belt misalignment in any weather and offers a 250% longer shell life.

The heart of the working end of all YeloRoll rolls is a high-quality, double-sealed, self-lubricating ball bearing system. Unlike the taper bearings used in conventional steel can rolls, YeloRoll runs smoother, cooler, and 55% quieter. Its carbon-fiber Combi-Cap™ aids in reducing noise as well as the shock and vibration encountered in steel can systems. YeloRolls weigh 60% less than same-sized steel can competitors.

Durable sling

Lift-It® Manufacturing Co., Inc. has released three new products. The patented, monofilament round sling cover of its inspectable round slings is transparent and provides for full inspection of the load-carrying fibers, leaving nothing to the imagination. It’s available in 2,650- to 31,000-pound vertical workload limits.

Dyneema® is a super strong, ultralight, polyethylene fiber that is very cut- and abrasion-resistant. The same yarn properties that provide cut resistance in gloves were used in the design of the CoverMax™ Sleeve, a Slingmax® solution providing the ultimate in synthetic sling protection.

Have you ever dropped a conventional, construction storage box? Call the manufacturer and you’ll soon discover that the box was never designed or intended to be used to transport materials by being lifted. Lift-It® engineered rigging boxes are specifically manufactured for the transportation of goods and materials as they are rigged and lifted to the desired location.

Absorb spilled hydrocarbons

Peat Sorb® is an environmentally and user-friendly hydrocarbon absorbent that is starting to be used by industry the world over. Peat Sorb® is a lightweight, nonbiodegradable natural product that absorbs and encapsulates hydrocarbons on contact, thus rendering the hydrocarbon nonhazardous, because it will not be released back into the environment. This feature allows for its safe disposal as ordinary garbage.

Peat Sorb will not pick up water but will separate the hydrocarbon from the water. It works on all types of hydrocarbons, such as light and heavy oils, gasoline, diesel fuel, polyester resins, and paints. Peat Sorb is a fume suppressant and is nonabrasive, which makes the workplace much safer. Clients are reporting substantial cost savings by using this product. Peat Sorb is available in loose form, socks, pillows, and barrel tops.

Online corrosion coatings life-cycle cost calculator

The American Galvanizers Association has launched a new web-based software program that automatically calculates the life-cycle cost of common coating systems in comparison to the cost of hot-dip galvanizing. The calculator, hosted at www.galvanizingcost.com, debuted in May 2007.

For several decades, the galvanizing industry has been educating architects, engineers, and specifiers about the considerable lifetime maintenance costs of a project. Until now, calculation of those costs has been cumbersome and often completely avoided. The new Life-Cycle Cost Calculator, based on standard financial equations of net future value (NFV) and net present value (NPV), delivers a quick and detailed comparison of initial cost, total project cost, and average equivalent annual cost (AEAC), all provided in a one-page printout.

The Life-Cycle Calculator allows the user to input variables such as environment where a project may be located, coating system type, shop or field application, cleaning grade, size of project, and estimated interest and inflation rates. This information can be used to estimate the life-cycle cost of galvanizing your next electric/utility product.

Nondestructive on-line condition assessment of T&D cable systems

CableWISE™ is a unique, nondestructive on-line electrical system condition assessment process that enables electric utilities and a wide range of commercial/industrial facilities to evaluate the condition of cable systems, transformers, and switchgear without removing them from service.

Knowing a cable system’s weaknesses enables owners, asset managers, and reliability engineers to be proactive in finding and fixing problems before they cause outages. CableWISE technology can successfully detect deterioration in cables, splices, and terminations on both new and aged cable systems while they remain energized. To date, over 50 million feet of cable system (predominantly distribution- and transmission-class) has had its condition assessed in the field. The technology is applicable to all cable types.

In January 2007, CableWISE was acquired by UtilX Corp. to complement its CableCURE® technology and services.

Design/build services

Hohl Industrial Services Inc. will demonstrate its comprehensive design/build services for the power generation industry and highlight recent work on the innovative Niagara Generation LLC biofuels conversion project. Hohl Industrial’s work will enable the Niagara Generation coal-fired plant in Niagara Falls, N.Y., to be powered by biomass and tire-derived fuel.

Hohl Industrial takes complete responsibility for the design, procurement, and construction of design/build projects. Its streamlined approach helps simplify the process and results in dramatic benefits. These include working with a single contract and a single point for all communications to ensure accuracy, simplicity, and speed. Minimal staff are required on the customer’s part, and the construction schedule is greatly improved because design and construction activities coincide for efficiency. No time is wasted waiting for a complete design package, bidding, walk-throughs, and bid reviews.

Hohl is an industrial contractor providing field construction and shop fabrication services across the Great Lakes and Northeast. Projects are carried out at fossil fuel, nuclear, hydro, biofuel, and wind generation sites.

Dual in-situ NOx/O2 monitor

HORIBA Instruments’ INM-700 in-situ monitor simultaneously captures NOx and O2 concentrations at high temperatures using a unique zirconium oxide sensor and nonextractive point measurement. The analyzer’s rugged, compact design allows for placement indoors or out. The probe may be mounted directly in the stack or close to combustion sources through a single port.

The INM-700 enables easy installation and operation for accurate measurement of NOx/O2 for real-time monitoring and control. It is ideal for use in coal-fired boiler applications such as point combustion emissions readings, or for selective catalytic reduction systems control, and is an inexpensive alternative to complex shelters. Combustion modification techniques such as low-NOx burners, overfire air injection, gas re-burn systems, boiler tuning, or combustion optimization programs used in emissions compliance strategies are only a few applications suited to this analyzer. The INM-700 is the right choice for a broad spectrum of applications spanning cogeneration facilities, industrial processing, and large, centralized utilities.

New PRB stacker reclaimer

Salt River Project of Phoenix, Ariz., has awarded BRUKS® Rockwood the contract to supply two circular overpile stacker/reclaimers (COSR) handling Powder River Basin coal at its Springerville Generating Station.

Rockwood’s COSR is specially equipped to handle the challenges often presented by PRB coal. Critical performance/cost benefits of the COSR include:

- A heavy-duty design that can withstand harsh operating conditions.

- 100% live storage and a fully automated system.

- Reduced operating and maintenance costs.

- Improved dusting control as compared with other methods.

- Complete U.S. supply and manufacture for its U.S. customers.

The Rockwood COSR system has proven its performance around the world handling a wide range of bulk materials in extremely harsh environments. This machine will be an instrumental component in the Springerville process when it begins commercial operation in December 2009.

Generator gas manifold system

E/One’s new Generator Gas Manifold (GGM) system is one of a range of standard or custom-designed products. From the point where hydrogen gas is received from the plant’s bulk supply or bottle manifold, E/One’s compact GGM monitors critical H2 and CO2 supply pressures and regulates the hydrogen supply to the appropriate machine gas pressure.

Manual isolation valves, arranged for easy end-user access, allow operators to control all facets of the purge process from a single location. A safety spool is an integral feature of the GGM and ensures that dangerous mixtures of H2 and air are avoided. The GGM system is typically incorporated into an E/One Gas Station (also available as a stand-alone system) and is combined with a standard Generator Auxiliary System (GAS) display or a customized configuration that can include a range of annunciator points relating to both the gas and seal oil system. Local display of critical values in the hazard area, and interface with the turbine/generator control system, are both standard features in any of E/One’s GAS displays.

Ladder alleviates suspension trauma

FrenchCreek Production Inc., a custom manufacturer of quality fall protection and rescue/recovery systems, has introduced the U-RES-Q, which is designed to not only alleviate suspension trauma in the event of a fall but also to allow a capable worker the option of climbing back to the working platform. The U-RES-Q is available as an option to many FrenchCreek shock-absorbing lanyards, but it is also available as an add-on option for any standard shock-absorbing lanyard and anchor.

It is common knowledge in the fall protection industry that every minute in suspension, after a fall, is crucial. At the slightest of falls, the lightweight U-RES-Q pouch releases into rescue mode by automatically ejecting a high-strength, 16-foot synthetic rescue ladder. At that point a worker can attempt to climb back to the working platform or simply stand on the ladder to relieve 100% of the harness pressure, increase blood flow, and ensure enough time for emergency response.

The U-RES-Q is to be used in conjunction with a full-body harness and a complete fall prevention/rescue program.

Maximize clinker grinder service life and availability

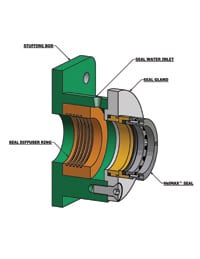

Helmick Corp. announces multiple options for establishing enhanced clinker grinder availability and dependable service life. One retrofit available is the HelMAX™ outboard-mounted mechanical seal.

Helmick offers a proven mechanical seal conversion for clinker grinders that should exceed the lifespan of the original packing configuration. HelMAX seals offer proven savings, demonstrated by a 20-year history of successful performance. Extend the life of your clinker grinder installation by converting to HelMAX seals and eliminate the packing problems that use up your manpower and maintenance budget.

Shaft deflection is no longer an operational concern, as the HelMAX seal attaches to and moves with the shaft. HelMAX seals are installed with an 18-month service guarantee.

Real-time baghouse data

Midwesco® Filter Resources Inc. has a new Black Box product that is an integral part of streamlining the dust collection process. Midwesco’s Black Box is designed to be a portable and/or permanent diagnostic system that spans the entire baghouse or dust collector application scenario, from monitoring airflow to troubleshooting and broken bag detection that integrates with real-time data. This is a vital asset for those who are still working to achieve MACT compliance.

“Strategic decisions regarding your baghouse or dust collector require real-time data analysis,” said John Brown, hardware and accessory product manager. “In our on-going effort to provide our customers with innovative solutions to increase their plant productivity and meet the latest market demands and shorten their time to market, we wanted to release the Black Box immediately. The Black Box will enable hundreds of thousands of plant and maintenance managers in organizations large and small to deliver accurate real-time baghouse/collector data in order to make strategic decisions for continued plant operations.”

Submersible drainage pumps

Grindex, the world’s third-largest supplier of submersible drainage pumps, has implemented a comprehensive restructuring as part of its company growth strategy. The “new” Grindex will soon launch an entirely new product series of extremely hard-wearing and service-friendly pumps. “The new Grindex will be a marketing and sales company making better use of the cooperative opportunities available within the ITT group,” said Grindex Managing Director Peter Schmid. “Examples of this include research and development and aspects of production. Our customers will benefit from a stronger partner providing high availability in terms of products, support and service.”

“With our own sales company and a well-developed global network of distributors we shall widen our usefulness as a dewatering partner, now being able to provide packages that include service and technical support. The new generation of pumps will be an important step in our new efforts in this direction,” Schmid said.

Grindex’s marketing of its submersible electric pumps is focused primarily on drainage, sludge, and slurry pumping. Company products are used wherever excessive water needs to be transported. The most important customers are construction and rental companies, mines, and larger retailers.

Thermodynamic modeling tools

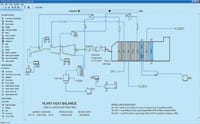

General Physics Corp. has released a new version of its VirtualPlant™ Software for solving power plant performance problems. VirtualPlant 2 provides power plant professionals with new thermodynamic modeling tools that are tightly integrated with GP’s EtaPRO™ System.

VirtualPlant is a first-principle-based software simulation solution enabling users to accurately model the performance of their fossil, combined-cycle, and nuclear power plants in both real-time and off-line environments. VirtualPlant users can easily compare actual plant performance with detailed model predictions to quickly identify performance gaps.

“VirtualPlant has established itself as an easy-to-use, operations-oriented tool for quickly assessing plant performance problems, evaluating boiler and turbine upgrades, and forecasting plant capacity,” said Richard DesJardins, director of performance engineering services. “Our customers are finding more and more uses for this powerful technology, which continues to provide additional value for their EtaPRO Systems.”

Membrane separation technology for water purification

Itasca Systems Inc. will highlight water purification technology using membrane separation. Itasca will emphasize its hollow fiber ultrafiltration (HFUF) membrane systems, reverse osmosis (RO) single- and double-pass systems, and electrodeionization (EDI) module systems.

HFUF membrane technology enables the use of surface water supplies as power plant feed streams. It is capable of filtering particulates down to 0.03 micron. The process is very efficient and has high recovery rates. The rugged PVDF membrane is resistant to acid cleaning, caustic cleaning, and disinfection with chlorine dosing.

An RO system’s cleaning ability, with a minimum of operator time and maximum flexibility, is an important part of design for a power plant. Itasca’s custom design approach allows for the plant engineer’s input on this and all aspects of the design.

An EDI system can minimize (or eliminate) the amount of acid and caustic used for water purification in a power plant. The EDI system will also require less space than a conventional automatic deionizer, which will save capital building cost.

Ion exchange resin cleaning process

Recirculation Technologies Inc. initiated the patent application process for its novel cleaning chemical and process, ReStore+, for removing organic foulants from anion ion exchange resins. In full-scale cleaning programs at pulp and paper mills and chemical plants, organically fouled anion resins had substantially better capacity and salt splitting capacity as compared to a conventional brine and caustic treatment called a “brine squeeze.” The throughput of the anion resins doubled, thereby decreasing regenerant chemical usage by 50%.

“With a product like synthetic ion exchange resin, which has been produced for over 50 years, innovations are tough to come by,” said Robert Finley, president of Recirculation Technologies. “I am proud that Bill Bornak, a co-founder of our company, has been able to develop a new ion exchange resin cleaning chemical and process so novel that we have applied for a patent. Used in conjunction with our years of expertise in cleaning resins, our excellent group of technical field specialists can bring a water treatment system back to efficient operation.”

Low-flow pumps

Gas Equipment Co. Inc., in conjunction with Corken (a Division of Idex Corp.) will display the newest addition to its small-flow aqueous ammonia forwarding pumps. The new additions are the low-flow (below 0.25 gpm and up to 3 gpm) magdrive gear pumps operating at motor speeds. Construction materials can be either poly or stainless steel.

These gear pumps enable extremely simple and cost-effective maintenance when required. Gas Equipment and Corken have a long relationship of providing solutions for ammonia-handling equipment for anhydrous ammonia or aqueous ammonia to NOx-reduction programs.

Motor and generator service

Once known as primarily a northern New Jersey company, Longo, the largest electrical-mechanical sales and service company in the tri-state area, is heading south. Long known for its expertise in a broad range of products, from motors and pumps to switchgear and drives, Longo has established a Philadelphia area Servicenter to provide its resources to companies along the Philadelphia-Baltimore corridor.

Longo’s scope of operation begins with on-site testing, diagnosis, and repair. Where necessary, field service teams are fully trained and experienced in the removal and reinstallation of even the largest and most complex motor and pump assemblies. In-shop repairs continue Longo’s tradition of quality repair and remanufacturing.

While Longo routinely handles motors in the thousands of horsepower and pumps with capacities of 100,000 gpm, it also offers more sophisticated engineering capability. Its technicians are factory-trained in the complex service and repair of high-speed, oil-free air compressors.

Longo is also looking ahead and moving upward—300 feet to be exact. Applying 60 years of motor/generator experience to wind generator service is just another natural extension of Longo’s capabilities.

Internal joint seal

Miller Pipeline Corp. offers WEKO-SEAL®, the internal joint seal—a trenchless system for internally and economically resolving joint leakage or infiltration. Seals are available for any pipe sized 16 inches in diameter and larger with penetration distances in excess of 1,000 feet. The WEKO-SEAL comes in a variety of widths but can also be used for continuous coverage of any distance through the company’s Sleeve/Seal capabilities. These seals are flexible rubber leak clamps that ensure a noncorrodible, bottle-tight seal around the full inside circumference of the pipe-joint area. Their unique design incorporates a series of proprietary and patented lip seals that create a leakproof fit on either side of the joint.

WEKO-SEAL installations are handled by the company’s confined-space-trained experienced technicians who have handled more than 260,000 failure-free installations in locations throughout the U.S., Canada, and Mexico. Hundreds of gas utilities, municipalities, and industrial plants have made them a vital part of their water, wastewater, and gas pipeline maintenance and rehabilitation efforts.

Advanced silicon carbide delivers high wear resistance

Blasch Precision Ceramics InVinCer silicon carbide parts offer excellent wear; chemical, oxidation, and thermal shock resistance; high thermal conductivity; and high-temperature operation.

Blasch’s new reaction bonded silicon carbide (SiSiC) offers the highest thermal conductivity to its maximum use temperature of 1,380C. Available products include burner nozzles, pump components, mechanical seals, micronizers, and cyclones. Custom shapes are also available upon request. Highly abrasive wear and corrosion applications include flue gas desulfurization nozzles, burner liner blocks, pipe bend liners, and other power generation applications.

Blasch’s recrystallized (RSiC) silicon carbide’s maximum use temperature is 1,610C. Available products include burner nozzles and specialized structural members, as well as custom-shaped parts.

Innovative seal for low-maintenance boiler seal replacement

Expansion Joint System’s seal that allows for minimal gas losses without high installation costs is now available. The Penetration Slider Seal (PS Seal™) may not only reduce gas leaks on your boiler but also reduce maintenance costs.

The PS Seal uses a floating ring design with patented stainless steel flow. The seals are compressed on assembly to provide minimal gas leakage during operation. As particulates build up in the seal and further restrict passage of gas, the gas leakage in the seal reduces over time. The stainless steel wire mesh seal can be replaced easily during shutdowns, eliminating the need to replace the entire unit.

Because these seals may be disassembled and repaired without cutting metal piping or welds, there is no need for specially trained on-site service technicians to perform the replacements. Standard sizes, 4 to 18 inches nominal diameter, are currently available. Axial movement is unlimited and standard seals are designed for ¼-inch and 1-inch lateral movements. These units will also accommodate the angular movement frequently present from pipe distortion.

Coal car topper system stops PRB dust emissions

Sometime this year, BNSF is expected to announce guidelines requiring the IDV.2 (Integrated Dust Value Version 2) levels to be no greater than 300 for all trains leaving the Powder River Basin region. Spraying coal in conjunction with better profiles is now the railroad industry’s answer to coal dust problems. Topper agents will reduce dust at levels approaching 100%. These guidelines are meant to reduce the IDV.2 levels down to 300 (which means 85% to 95% reduction in dust levels) on all coal loads.

Midwest Industrial Supply manufactures a customized Coal Car Topper System that extends over railcars to apply Soil-Sement® on coal and other materials to keep them from blowing into the air. The Coal Car Topper System can have electronic detectors on the arm that can be automated to raise and lower as a train approaches and leaves and efficiently apply dust suppressant to the coal. Midwest’s Coal Car Topper Systems have been successfully utilized for several years to treat railcars at coal mines in extreme Canadian temperatures.

Soil-Sement is an environmentally safe chemical-dust-suppressant topper agent. In order to be included in the BNSF Coal Car Topper Study, it was subjected to and passed the following tests: Simpson Weather Associates Laboratory Testing, BNSF Corrosion and Safety Testing, BNSF Performance Standards Testing, and Southern Company Burnability Testing.

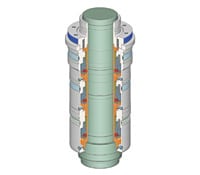

Hydrodynamic seal

Sulzer Pumps will be displaying its Balanced Stator™ seal, an ultra-high-performance cartridge unit that provides lifespan and leakage control unmatched by conventional seals. Employing patented flexible stator geometry, the Balanced Stator seal automatically compensates for pump shaft deflections. Leakage is predictably controlled to less than 0.03 gpm (0.11 liter/min). Maintenance-free periods extend from four to eight years.

The hydrodynamic seal design has three-stage seal redundancy that hydrostatic seals simply cannot match. The Balanced Stator seal is available for any reactor coolant or recirculation pump. Sulzer provides replacement mechanical seals for other manufacturers’ reactor coolant pumps (RCP) and installs the Sulzer Balanced Stator seal in RCPs from all the major original equipment manufacturers. Sulzer’s updated Balanced Stator seal is a proven product, ready to solve seal reliability, maintenance, and cost problems. Sulzer’s seal development and testing experience dates from 1961, and the seal’s field-proven performance through all types of transients is a matter of record. The company’s on-site services and product development capabilities make it proficient at providing retrofit solutions.

Fast degassing

The Lectrodryer Fast Degas CO2 Evaporator system allows for quick degassing of the generator while preventing lines from clogging due to ice formation as a result of CO2 expansion. The Fast Degas CO2 Evaporator system helps reduce the time and cost involved during outages by allowing the generator to be degassed and brought back on-line much more rapidly. This system also provides an important safety benefit by rapidly blanketing the generator with inert gas in times of upset conditions or emergency situations.

The Lectrodryer Fast Degas CO2 Evaporator system allows the generator to be fully degassed in less than 20 minutes. The CO2 Evaporator controls the CO2 pressure and heats it. This system is designed to maintain a minimum temperature where the CO2 is completely evaporated and at a state where further depressurization will not form solid particles or extremely low temperatures.

Thermal spray systems defend against erosion and corrosion

Advancements in material manufacturing technology have lead to the development of the next generation of twin-wire electric arc spray wires for the thermal spray coating industry to assist clients with run length reliability of equipment.

Nooter Construction Co. (NCC) has more than 110 years industrial experience. Its affiliate companies are St. Louis Metallizing, with 50-plus years in the shop-applied coating industry, and ArcMelt, manufacturers of proprietary spray wires and powders. Together, they are now capable of field-applying high-quality thermal coatings on equipment and components. With NCC’s ability to apply thermal coatings using the twin-wire electric arc process, they can offer clients a highly efficient and cost-effective field-applied alternative to weld overlay for the protection of equipment.

A significant advantage of using a thermal coating instead of weld overlay is that there is no heat-affected zone or metallurgical impact to the base material or substrate. And, because there is no degradation of the substrate, coatings maybe applied numerous times without affecting the integrity of the substrate material.

Collapsible workbasket

Since 1988, Lisbon Hoist Inc. has been manufacturing equipment in the U.S. This past year the company announced two new products.

The 143-200/143-210 Series collapsible workbasket (patent pending) is easy to tear down into 11 parts. The workbasket will fit through openings that are 18 inches round, 14.5 by 14.5 inches square, or 18 by 12 inches rectangular. Assembled weight is 100 to 105 pounds, depending on whether you purchase a low-headroom or standard model. Its capacity is 500 pounds, and it’s available in powder-coated yellow and blue.

The 144-010 bosun chair/bucket holders are designed around the company’s Spirit hoist. Construction is welded aluminum, and it is powder coated with pneumatic wheels (or optional foam fill wheels). Bucket holders and wheels are adjustable in 1-inch increments. Bucket holders come with a padded high-back seat for comfort, weigh 52 pounds with bucket holders and 37 pounds without, and have a capacity of 500 pounds.

Work chairs

United Group’s new IRONHORSE Seating™ 4000LT sets the new standard in executive class, ergonomic seating. The company’s target was to design and engineer the finest ergonomic chair on the market today, using only the finest materials. The heavy-gauge, tubular steel frame is robotically welded for consistent quality. The easy-to-adjust, heavy-duty automotive recliner locks the backrest into place.

The laser-cut, 14-gauge steel seat pan provides total support for the anatomically contoured foam cushion. The premium grade, high-density foam cushions are injection molded for total tolerance control. The finest Italian leather hides are cut on a Gerber CNC cutter and then precisely tailored. Multi-density foam is sewn into the covers for a soft yet supportive feel. You will not sink into these chairs but they will feel soft when you first sit and remain supportive for the entire day.

The 4000LT features a full 45 degrees of total recline. The fully articulating headrests have received accolades as the chair’s best feature. These chairs will accommodate individuals of 6 feet, 6 inches and 350 pounds.

Environmentally safe spill response and retrieval systems

C.I.Agent Solutions’ complete C.I.Agent Rapid Response Systems are easy-to-use and easy-to-store packages containing a variety of spill-response materials and equipment designed to meet hazmat needs on land and water.

Unlike the traditional commodity spill kit, which requires additional dollars for proper disposal, C.I.Agent is nontoxic, noncarcinogenic, and nonhazardous. It solidifies liquid hydrocarbons such as gasoline, oils, diesel, and sheen upon contact into an inert solid rubber-like mass that floats. C.I.Agent Rapid Response kits come in standard and customized sizes.

C.I.Agent is listed on the EPA, NCP Product Schedule and has been pre-authorized for use on oil spills, in free form, by the RRTs in EPA Regions IV, III, and the Caribbean (other regions pending). This listing does not mean that the EPA approves, recommends, licenses, certifies, or authorizes the use of C.I.Agent on oil discharge. This listing means only that data have been submitted to the EPA as required by subpart J of the National Contingency Plan, 300.915.

Wind energy composites

With more than 40 years of experience, Fibergrate Composite Structures Inc. is the leading manufacturer of fiberglass reinforced plastic (FRP) products for industrial and commercial use globally. The company is now involved in the manufacture and supply of composite wind turbine blades and nacelles. It is also involved in providing composite solutions for coal-fired power plant scrubber systems, including various internal components for both cross-flow and Chiyoda jet bubbling reactor flue gas desulfurization scrubbers.

Fibergrate has supplied the electric power industry over the past 40 years with traditional FRP products such as grating, handrail, ladder, and structure used for filters, screens, catwalks, walkways, decking, and water treatment.

Joining the StonCor Group, an operating company management unit in the industrial division of RPM International Inc., in 1997 added a key element to a group of companies dedicated to combating caustic and corrosive environments. RPM is the world leader in specialty coatings serving both industrial and consumer markets.

Inspections, education, and metallurgical analysis

Long-time industry leader in boiler inspection services and educational training, United Dynamics Corp. is coupled with the wide-ranging metallurgical processing services of David N. French Metallurgists. Their combined services provide organizations within the power industry complete all-inclusive services resulting in reduced EFOR rates.

Clients experience effective results with the availability of dual services provided by the experience and expertise of the two companies, which are industry leaders in boiler inspection, education, and metallurgical analysis. One current client said, “We are enjoying a great year from a boiler reliability standpoint and realize you contributed to this in a major way. We appreciate what you do and look forward to working with you again.” Another commented, “We have seen the proven track record in EFOR. Our rate has improved from 2.43 average in our plant in 2002 to .97 at current. We value this working relationship.”

Reduce flyash loss on ignition

SAS Global Corp.’s Total Solution Approach (TSA) is a custom-tailored solution based upon the customer’s specific goals. SAS works closely with customers to identify potential opportunities in combustion improvements that can directly lead to reduced flyash LOI (50% or more), reduced NOx emissions (20% or more), reduced slagging, reduced fuel costs and opacity, increased boiler efficiency and generation, and increased flame stability using the company’s patented in-line diffusers.

One case history’s specific improvements for a Babcock & Wilcox 650-MW cell burner with 48 DZB-4R burners fed by six MPS-89 mills firing an eastern fuel were as follows: pre-TSA: O2 (%, dry) = 4.5, NOx (lb/MBtu) = 0.463, flyash LOI (%) = 10.2; post-TSA: O2 (%, dry) = 3.8 (16% improvement), NOx (lb/MBtu) = 0.399 (14% improvement), flyash LOI (%) = 3.1 (70% improvement)

The primary goal was flyash LOI reduction so that the ash could be sold. The pre-TSA NOx was measured with SNCR and OFA; the post-TSA NOx was measured without OFA and SNCR. These results have been maintained for over six months.

Stator windings

National Electric Coil’s high-voltage generator stator windings are available for any configuration or brand of machine. NEC supplies replacement stator windings for current machine designs, and it specializes in the supply of windings for outdated or legacy brands that are no longer supported by the OEM’s factories. NEC also supplies replacement coils of the most complicated technologies, such as a 900-degree Röebel transposition in an inner gas-cooled winding for a 600-MW generator, an inner water-cooled winding for a 900-MW base-loaded generator, or an unusual concentrically wound winding with external transpositions for a legacy machine.

NEC’s new turbogenerator rotor windings are made with edge-bent or fabricated corners. Slot sections may be made with radial, axial, and/or diagonal cooling passages. In some cases, old copper can be refurbished and reinsulated.

NEC’s proven design and manufacturing process is ISO 9001-certified.

Water treatment

SAMCO Technologies Inc. has entered into a licensing agreement with Rohm and Haas Chemicals LLC (NYSE:ROH), a world leader in the manufacture, application, and use of ion exchange resins. The licensing agreement grants SAMCO certain exclusive marketing and manufacturing rights to Rohm and Haas’ revolutionary and innovative Advanced Amberpack™ technology for deionization, dealkalization, and softening of water for industrial applications. This process utilizes a patented fractal distribution system in a packed bed countercurrent ion exchange system that results in a near-perfect plug flow regime and exceptional separation of waste fractions during the regeneration cycle.

SAMCO Technologies is a single-source provider of solutions for water, wastewater, and process purification and separation. It supplies equipment, systems, and turnkey facilities including a complete line of membrane, ion exchange, thermal, and physical/chemical separation capabilities. SAMCO provides innovative, cost-effective solutions to industrial customers by combining engineering, technology, integration, manufacturing, and project management talent with a unique business system design.

Aqueous ammonia forwarding pumps

Gas Equipment Company Inc., in conjunction with Corken (a Division of Idex Corp.), will display the newest addition to its small-flow aqueous ammonia forwarding pumps. The new additions are the low-flow (below 0.25 gpm and up to 3 gpm) magdrive gear pumps operating at motor speeds. Construction can be of either poly or stainless steel.

These gear pumps offer extremely simple and cost-effective maintenance when required. Gas Equipment and Corken have a long relationship of providing solutions for ammonia handling equipment for anhydrous ammonia or aqueous ammonia to NOx-reduction programs.

Hazardous application LED lights

Unimar has released new LED area lights: LEDBright (standard) and SafeSite Series (hazardous locations fixture). Their rugged solid-state design creates a new era in which failed lamps and expensive relamping costs become a thing of the past. These fixtures will replace traditional high-pressure sodium (HPS), metal halide (HID), and fluorescent lighting fixtures to achieve a better, whiter grade of lighting with an instant “On” feature so they can be used as needed, thus providing higher quality lighting while eliminating wasted energy.

The first of its kind, SafeSite is designed to replace 75-W to 250-W HID light sources in hazardous location applications. The fixture provides better quality light, higher fixture efficiency, and 30% greater energy efficiency than traditional HID light source technology. The SafeSite and LEdBright fixtures are perfect for applications where shock and vibration are present, which shortens the life of traditional lights. They provide extremely long life (estimated 15 years) before service is required. With the great reduction in power needed to operate these new fixtures, they will also assist in efforts to reduce energy use and greenhouse gas emissions.

Return idler guard

The ASGCO SAFE-GUARD line that works on CEMA B, C, and D series idlers up to 7 inches in diameter has been expanded to include CEMA E & F return rollers. The transverse support of the new heavy-duty SAFE-GUARD is angled to provide a more robust design that prevents bending and is sized to fit over CEMA E & F return roller brackets. Both the mounting brackets as well as the end plates are made from powder-coated A-36 steel.

ASGCO has long recognized the importance of ensuring safety in the workplace. The lightweight, ASGCO SAFE-GUARD return idler guard was designed to prevent injuries from pinch points and to catch the return idler if it should fall. Installation of SAFE-GUARD on a conveyor belt return idler helps to protect workers from the hazard of contacting the exposed idler.

The durable UHMW slotted cage is designed to prevent material build-up and enable easy clean-up. Removing just two stainless steel pins to drop open the side of the cage gives full access to the roller and allows for ease of replacement and maintenance. All ASGCO SAFE-GUARDs are fully adjustable for a wide range of idler sizes and belt widths up to 96".

Investment Banking Services announces new director

Investment Banking Services (IVS), a sister company of BIC Alliance, is proud to announce Tom Hudgins’ recent addition to the company as a managing partner. Hudgins, a veteran investment banker, in his new position will collaborate with IVS President Thomas Brinsko and Managing Director John Zapalac based out of the company’s new, expanded Houston office. Hudgins will interface with existing clients and will focus on deal structuring with Zapalac.

IVS offers investment banking services to the heavy process and power industries. In the past two years, IVS principals have closed four deals with an aggregate value of $70 million and have three deals under letter of intent that have an aggregate value of $75 million. IVS is in the business of connecting business and industry for the betterment of all by offering complete investment banking services to help buy, sell, or grow companies in the industrial marketplace.

Magnets for contaminant separation

Eriez, the pioneer of permanent magnets, has a new line of Suspended Permanent Magnets with operating advantages never before available. Suspended Magnetic Separators are designed for applications where ferrous contaminants are to be removed from bulk products, either on a moving conveyor belt or chute.

The CP 20/80 utilizes a permanent magnet circuit to provide a continuous and uniform magnetic field across the feed belt to optimize separation efficiency of damaging tramp iron. The self-cleaning feature supplied with the unit provides for automatic removal of accumulated tramp metal. Features include low operating cost, no electrical maintenance on the magnet, no costly shutdowns, uninterrupted magnetic protection, simple installation, powerful magnetic field, and no power requirement.

Eriez is recognized as a world authority in advanced technology for magnetic, vibratory, and inspection applications. The company’s magnetic lift and separation, metal detection, x-ray, materials feeding, screening, conveying and controlling equipment have application in the process, metalworking, packaging, recycling, mining, aggregate, and textile industries.

Real-time software for plant optimization

NeuCo Inc., a leading provider of optimization software solutions to the electric power industry, has successfully completed a four-year optimization software development and demonstration project at Dynegy’s Baldwin Energy Complex in Baldwin, Illinois. The $19 million Clean Coal Power Initiative project was a cost-shared effort between NeuCo Inc. and the DOE. Dynegy’s Baldwin plant now hosts the nation’s most significant integration of real-time asset optimizers for coal-fired power generation.

The project’s objective was to improve coal-based generation’s emission profile, efficiency, maintenance requirements, and plant asset life. Separate but integrated real-time software products were developed for combustion, sootblowing, SCR operation, unit thermal performance, and plantwide availability optimization. While the individual solutions provide stand-alone functions and benefits, they are essentially configurations of a common, distributed platform—enabling synergies between the optimizers.

Results at Baldwin include reduced NOx emissions; improved fuel efficiency; commensurate reductions in greenhouse gases, mercury, and particulates; reduced SCR ammonia consumption; more reliable cyclone boiler operations; and faster discovery, prioritization, and diagnosis of plant equipment issues.

New weld-purge systems

COB Industries Inc. has introduced, for the first time in the U.S., the latest technology and design advancements for the fastest possible weld-purge systems on the market. The Argweld® brand has been known for many years to offer some of the best weld purging systems and purge monitors in the industry, and the Quick-Purge Systems that were introduced a couple of years ago immediately became high-demand items at liquefied natural gas sites, power plants, and other applications involving the welding of larger-diameter stainless steel pipe across the U.S. and Europe.

Using valuable input from users in the field, a new generation of Quick-Purge Systems has been developed. The latest versions of the Quick-Purge Systems offer new features and technology, including multiple exhaust ports for faster purging, additional relief valves to prevent overinflation, and multiple fill lines for use with varying flow rates. This all adds up to the fastest, most effective, and user-friendly system available. This translates into huge cost savings in time, manpower, and gas.

New boring mill capacity

Penn Iron Works Inc.’s Nuclear Quality Fabrication/Machining facility has been upgraded with the addition of two new CNC horizontal boring mills. The first is a floor-type 6-inch machine with vertical capacity of 138 inches and horizontal capability of over 34 feet. The second machine is a table-type 5-inch mill with an operating envelope of 98 inches by 98 inches.

These new additions will enhance our objective of providing quality machined fabrications meeting 10CFR50, Appendix B; ASME Section III “NPT” and “NS”; ASME Section I “S”; ASME Section VIII pressure vessel “U”; NBIC “R”; government, military Mil-I-45208 and Mil-Q-9858; DOE (10CFR830); and commercial requirements for pressure vessel and structural components.

The company’s extensive materials experience includes carbon steels; martensitic steel; stainless, duplex, and super duplex stainless; 6% moly; aluminum bronze and nickel aluminum bronze; hastelloy; inconel and incoloy; nickel; monel; and copper-nickel alloys.

End use of the company’s fabrications includes a wide variety of processing lines, pump and compressor applications, municipal utility systems, government sites, U.S. Navy ships, and numerous nuclear and fossil-fuel electric power plants around the world.

Energy-absorbing dynamic restraint

LISEGA’s new E-BAR technology provides unique energy absorption for seismic and whip restraint applications. Utilizing new patented technology, LISEGA has developed and installed the E-BAR, a new-generation dynamic restraint that’s ideal for both nuclear and fossil generating plants.

The E-BAR is fully integrated into the LISEGA line of dynamic restraints and accessories. Using the E-BAR as a gapped restraint significantly reduces the number of snubbers required for seismic protection. Unlike snubbers, the E-BAR does not require operational readiness testing per ASME-ISTD, which saves time and money. E-BAR meets ALARA requirements during outage I-S-I activities. NRC safety evaluation of the E-BAR Topical Report has found it acceptable for referencing in licensing applications.

The E-BAR can be custom designed to go plastic at a predetermined load through deformation of the outer metal housing. Acting as a “fuse,” it controls pipe displacement and stresses to acceptable values while limiting structural loads to as little as one-eighth of that seen using conventional restraints.

Two E-BARs installed at 90° provide the ultimate pipe whip restraint, absorbing energy in all directions perpendicular to the pipe axis, unlike conventional “U-bolt” designs, which limit pipe displacements in only one direction.

Bearing repair

Kingsbury Repair & Services Division recently opened the doors for a new repair facility for the western states. It is a full-service facility capable of handling repair sizes over 110 inches. The company is also offering bearing repairs for replacement upgrades. Older bearings have had design improvements made over the years and should be looked at to see if a better fix is available. Kingsbury can offer these services because it has been involved daily in new product design and research for almost 100 years.

Kingsbury also offers a turbine-generator bearing failure analysis program that enables customers to track repairs; see machined tolerance; view individual drawings and assembly drawings; and see inspection reports, shipping reports, and pictures. These are all available on the company’s web site with the customer’s password.

Upstream approach to SO3 control

By employing Fuel Tech’s upstream approach using the Targeted In-Furnace Injection™ (TIFI™) process, multiple significant performance benefits in addition to blue plume control can be achieved. Recent data indicates that this innovative approach to SO3 control reduced fuel and operating costs, resulting in greater than 4 to 1 return on investment.

Utilizing the TIFI program for SO3 control leads to better slag and fouling control. As a result, a cleaner furnace not only produces less SO3, it also improves heat transfer, boiler efficiency, and clinker grinder performance. Reduced slag and fouling also reduces outage cleaning times, helps decrease the need for load shedding, reduces clinker growth, and improves ash handling characteristics while reducing the total toxic release.

Absorbent beads

Award-winning Drain Protection Systems (DPS) from Imbibitive Technologies America are designed to allow rainwater to drain but automatically seal the leak path in the event of an oil release. Imbiber Beads®, used by the DPS, selectively remove organic liquids, including PCBs, from water. Imbiber Beads are discussed in the Design Guide for Oil Spill Prevention and Control at Substations, USDA-REA (RUS) Bulletin 1724E-302, the USEPA final rules for SPCC compliance, 40 CFR Part 112 (2002) as well as in the IEEE Guide for Containment and Control (IEEE Std. 980).

Imbiber Beads are the only true absorbent (ASTM F716) “engineered” for organic chemicals. They are not an adsorbent, and they are not a thickener/solidifier. Imbiber Beads will not dissolve in excess liquid. Water can not be absorbed by Imbiber Beads, as they are hydrophobic.

Imbiber Beads Imbicator® spill maintenance products (booms, blankets, pillows, and packets) are also available for capturing and containing compatible organic chemical (fuels, solvents, mineral oil) releases.

Portable emissions analyzers

Advanced engineering, superior innovation, and over 40 years of measurement know-how have produced the finest portable emissions analyzers for the power industry. The Testo 335 combustion analyzer delivers the power of large suite-case analyzers in a rugged, convenient, handheld. The flexibility to test virtually any combustion application coupled with state-of-the-art software make it an essential tool for combustion tuning and troubleshooting. Quick set-up, user-defined soft keys, and intuitive easy-to-understand pull-down menus make it a breeze to use.

Precalibrated, true plug-and-play sensors are the keystone features of Testo analyzers. Special features like the special gas paths provide the convenience of “in-the-stack” start-up (and zeroing), thereby eliminating the hassle of repeated probe removal. The wide array of probes and hoses are designed for any test scenario.

Coal-blending software

SABIA Inc., a leader in bulk material elemental analysis, has teamed up with Ready Technologies Inc. to provide power plants with a seamless interface between their existing control systems and their fuel management systems to automatically achieve targeted coal qualities to improve operational efficiency and profitability by delivering the right fuel blend at the right time.

Ready, a global leader in automated blending systems and integration services, has installed its CoalFusion™ blending software at NRG’s Limestone Power Plant in Jewett, Texas, where SABIA’s Model XC-5000 analyzer is also in operation.

SABIA is a privately held, venture-backed firm established in 2000 by the scientists and engineers who originally commercialized prompt gamma neutron activation analysis (PGNAA) technology in the late 1980s. Customers use SABIA analyzers for run-of-mine, sorting and blending applications and for quality control. SABIA introduced its flagship line of on-belt analyzers in 2003 in response to the demand for affordable, real-time information of the quality of bulk materials in the cement, coal, and coal-fired power industries.

Engine-starting battery charger

La Marche has released a new ESCR engine-starting battery charger product line. This product line incorporates microprocessor-controlled SCR technology and is suitable for various types of batteries, such as flooded lead-acid, VRLA, and NiCad. Along with its easy-to-use control panel and informative LCD display, the charger meets NFPA110 requirements.

The two-line LCD displays volts, amps, and alarms. Automatic input sensing for 120/240 60 Hz (optional 50 Hz) does not require any tap changes, and multi-output (12V/24V) makes this product line flexible and convenient for multiple jobs. The ±0.5% regulation, temperature compensation, battery check, equalize timer, and adjustable output voltage and current limiting ensure longevity and performance for your batteries. This economical solution equipped with rich features also incorporates La Marche quality and reliability.

Clean renewable energy technology for gas turbines

LPP Combustion LLC recently demonstrated natural gas–level emissions using bio-derived ethanol (ASTM D-4806), palm oil–based biodiesel, and soy oil–based biodiesel during gas turbine combustor testing. Emissions of nitrogen oxides, carbon monoxide, sulfur dioxide, and particulate matter (soot) were the same as natural gas–level emissions achieved using current dry low-emission gas turbine combustion technology. In addition, the combustion of these liquids produced virtually no net carbon dioxide emissions.

The successful demonstration using these renewable fuels shows the LPP System is an enabling technology that allows for the cleanest possible use of biofuels in combustion devices without the use of post-combustion pollution control equipment. The LPP System is a viable alternative for power producers to create renewable energy for gas turbines and to help meet renewable power supply mandates.