Transformative Coal Power Technologies Take Shape

The coal power industry acknowledges that to play a stable role in future power markets, it needs to modernize, and perhaps even overhaul its long-held status as a “conventional generator.” Could new technology give it the reboot it needs?

At its annual meeting in San Antonio, Texas, last November, the National Association of Regulatory Utility Commissioners (NARUC) hosted a debate that featured the heads of U.S. trade organizations representing coal, gas, nuclear, energy management, renewables, and energy storage. Michelle Bloodworth, president and CEO of America’s Power, a group that represents the nation’s coal power generators, held her own as other participants painted the resource as polluting, stodgy, and outdated. “I do understand that some people want coal to go away, but those people also refuse to acknowledge that coal keeps the lights on regardless of the circumstances,” and has done so as the cheapest resource for decades, she said.

But with reliability as its most valuable attribute, coal generators, like other resource providers on the grid, are adapting to changing market conditions to accommodate the surge of cheap natural gas, and the variability of renewables. And, far from being obsolete, Bloodworth argued, the industry—which still has a 300-year supply of coal but has suffered setbacks owing to environmental policies and “market distortions”—has embraced innovation and technology to remain part of the “all-of-the-above” strategy.

New coal technologies will “require a different way of thinking,” and “it’s certainly going to take time and a significant amount of research and development [R&D] dollars and incentives,” Bloodworth told POWER later in an interview. All of it will hinge on a “cost-benefit test,” she noted. For existing plants, that will be whether it makes sense to make crucial changes considering a plant’s useful life, and for new plants, whether installation will guarantee cost-competition in a rapidly changing market. That’s why America’s Power has been advocating so strongly for fair fuel security and resilience valuation.

“It would allow more utilities and co-ops and generators to make these investments and allow the [existing] coal fleet to operate at least for its expected intended life, because we think having stranded cost and investment is not a good thing for consumers,” she said. “It doesn’t mean the coal industry doesn’t support the ‘all-of-the-above’ energy strategy—it’s about keeping the advantageous attributes of the coal fleet.”

Coal Plants of the Future

At the Department of Energy’s (DOE’s) National Energy Technology Laboratory (NETL), cost-effectiveness of new technologies is a major priority—but so are efforts to bring existing coal plant technologies to market in the near-term (between the next three to five years) under its newly launched Transformative Power Generation Program. Echoing other coal technology advocates—such as the International Energy Agency’s IEA Clean Coal Center (CCC)—it envisions that coal power will need several critical attributes to compete in future markets:

High overall plant efficiency. Plants will need to achieve a heating value of 40% or higher at full load over most of the generation range. They must also minimize water consumption.

Smallness or modularity and be fast to build. Plants must be compact, modular, resilient, and flexible, and be no larger than 50 MW to 350 MW to minimize design, construction, and commissioning schedules.

Near-zero emissions. Future designs and retrofits should emit less carbon than natural gas power generation technology.

Highly flexible. Ramp rates and minimum loads must be compatible with 2050 estimates of renewable energy integration. They must also be able to integrate with thermal or other energy storage to mitigate inefficiencies and equipment damage, or be capable of firing other fuels, including natural gas and hydrogen. Additionally, they must be able to integrate with coal upgrading or other plant value streams, such as co-production.

Enhanced operations and maintenance. They must incorporate advanced monitoring and diagnostics to reduce downtime.

Encapsulating most of these attributes are new designs that incorporate novel cycles or combustion systems. Among conceptual designs the DOE announced it will bolster with $7 million in funding under its Coal FIRST (Flexible, Innovative, Resilient, Small, Transformative) R&D program last October, for example, is 8 Rivers Capital’s efforts to integrate coal gasification into the Allam Cycle technology currently being proven by NET Power in Texas, a supercritical carbon dioxide (sCO2) project that could boost net coal power efficiency to the mid-to-high 40% range.

Another project spearheaded by Echogen Power Systems, the Gas Technology Institute, and the Electric Power Research Institute (EPRI) will study an advanced technology coal-fired power plant that will integrate three innovative technologies: sCO2 power cycles, pressurized fluidized bed combustion, and electrothermal energy storage. “These technologies will deliver the key plant characteristics of compactness, efficiency, modularity, and operational flexibility needed for coal-fired power plants to remain competitive in a rapidly changing energy market,” the developers said.

Another interesting concept, led by CONSOL Coal, WorleyParsons Group, and Farnham & Pfile, also pairs the pressurized fluidized bed combustor and a supercritical steam cycle with Benefield CO2 capture, and promises to operate flexibly and accept a broad range of coal qualities, including waste coals. Barr Engineering, along with Doosan Heavy Industries, the University of North Dakota, Microbeam Technologies, and Envergex, meanwhile, are exploring integrating a 250-MW ultrasupercritical plant with an 80-MW natural gas-fired turbine and energy storage to help enable rapid startup and load changes. Finally, the DOE is also backing Nexant’s and Bechtel’s efforts to study a modular plant that uses a coal-based “fluid” (in either slurry or micronized form) in a reciprocating engine with a conventional gas turbine in a reheat Brayton cycle—but also a steam Rankine bottoming cycle to maximize thermal efficiency.

Several oxy-combustion and chemical looping combustion projects are also under the DOE’s purview. These include a project to design a 10-MWe combustion pilot to validate the performance of flameless pressurized oxy-combustion technology for a broad range of coals on a large pilot scale (50 MWth). The project has heavyweight partners: Southwest Research Institute (SwRI), ITEA, Jacobs, EPRI, GE Global Research, and Peter Reineck Associates.

A different pilot project spearheaded by Babcock & Wilcox and Ohio State University, meanwhile, will explore development of an iron-based coal direct chemical looping (CDCL) technology. If successful, the small 25-kWth pilot could be expanded into a 10-MWe pilot that will likely be hosted by the Dover Light & Power plant in Dover, Ohio. “Integrating the design with existing steam cycle and balance-of-plant equipment at a selected host site represents a substantial step toward commercialization of CDCL technology,” the developers said.

Existing Coal Plants

For existing coal plants, the technology focus appears squarely on improving efficiency and flexibility. But as IEA CCC analyst Dr. Malgorzata Wiatros-Motkya explained, no “one-size-fits-all” solution exists to make a coal plant flexible, mainly because flexibility requirements differ depending on grid characteristics, market designs, and cost factors. “For some, achieving low minimum load in important, while for others, it is all about fast startup and rapid load ramp rates.” However, flexible plant operation can have a “significant impact” on all areas of a coal-fired plant due to the increase in thermal and mechanical fatigue stresses, which could reduce the lifetimes of many components, reduce heat rates, and ramp up operating costs on average by 2% to 5%, Wiatros-Motkya said.

|

|

1. EnBW’s 1985-built Heilbronn power plant has a once-through, tangentially fired boiler with hard coal supplied by four bowl-type mills. Originally designed to operate at 30% minimum load, it has undergone several modifications to achieve 10% net (15% gross) minimum load. In 2018, it added a 5.6-MWh lithium-ion battery system to help it better respond to fluctuating grid demand. Courtesy: EnBW |

Generally, however, flexibility can be improved through new technologies, modifying existing or adopting new operating procedures, and staff training. In Germany, for example, some coal plants have implemented a minimum load of 10% by ensuring stable combustion through a combination of measures (Figure 1), including optimization of coal fineness and air-fuel flow, indirect firing, changing the size and number of mills, and reliable flame monitoring, she said.

Especially notable are improvements to startup, which, as Wiatros-Motkya explained, often involves complex and expensive procedures because they require auxiliary fuel, such as gas or oil. One development that is already standard in China today is plasma oil-free ignition, which involves igniting coal with a hot plasma flow. In China, the cost of a 10-burner system is about $2 million, however, and the 250-hour life of the electrodes is still limiting, she said. More insights could come from a DOE-backed $4.5 million full-scale plasma ignition and combustion stabilization demonstration project that GE Steam Power began this September at Rocky Mountain Power. GE suggests the technology could save customers “millions of dollars” by eliminating fuel costs and providing a stable low-load flame.

Among other “near-term” DOE-funded projects is development of Oceanit Laboratories’ HeatX composite coating material. Designed to reduce fouling and promote drop-wise condensation, the coating could be applied as part of regular maintenance to existing in-service exchanger units that have been pre-fouled, as well as to seawater-fed shell and tube heat exchangers to reduce biofouling. Also notable is EPRI’s research to determine whether it is technically achievable and cost-effective to upgrade subcritical U.S. coal plants (ranging in pressure from 2,300 psi to 2,600 psi) and supercritical plants (3,400–3,600 psi) with nine retrofit options that raise steam temperatures from 1,000F to 1,350F, rendering them into ultrasupercritical and advanced ultrasupercritical units. That project is slated to be wrapped up in January.

The Promise of Digitalization

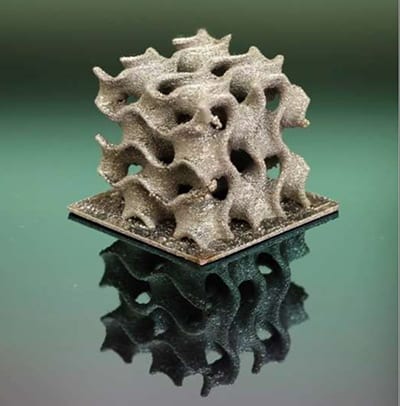

Also notably underway are technologies to improve component manufacturing. Advanced manufacturing includes a broad range of tools, technologies, and processes, which encompass additive manufacturing (such as 3D printing), roll-to-roll technologies, and process intensification, and they promise to boost the efficiency and economics of component design and manufacturing of new systems. Lawrence Livermore National Laboratory (LLNL), for example, is studying multi-scale, multi-material component development for heat exchangers in sCO2 plants (Figure 2), and it suggests its highly efficient gyroid-configured heat exchangers could improve heat transfer efficiency by an order of magnitude over tubes and flat plates. Meanwhile, NETL is exploring how 3D-printed components could solve hydrogen combustion challenges by creating parts that better balance ignition delay timing, low density fuel mixing, and flame speeds to reduce NOx emissions, or to develop improve anodes and cathodes for use in solid oxide fuel cells. Also under scrutiny are intricate casting techniques that could improve manufacturing of turbine blades with complex geometries, and new modes of materials modeling that help evaluate the economics of new materials for boilers exposed to cyclic loading.

Other entities around the world are researching technologies that include advanced and flexible electronics—which for example could allow sensors to be embedded in critical, geometrically complex components—integrated computational materials engineering; modularization; automation and control; smart sensors; and novel materials development.

At the same time, digitalization and big data are providing deep insight into the behavior and performance on a wide scale, from component to overall plant to the entire enterprise. As one of many examples, Mitsubishi Hitachi Power Systems in June 2018 incorporated its first boiler combustion tuning system employing artificial intelligence at Taiwan’s Linkou Thermal Power Plant. And GE, which has for some years offered a boiler module designed to improve efficiency by working with existing distributed control systems, is today focusing efforts on creating digital “twins” of coal plants based on an extensive “learning model” library of coal plant components to determine component health and visualize optimization opportunities that could help deliver up to 30% faster ramp rates.

As the IEA CCC’s Dr. Wiatros-Motkya noted, perhaps the biggest gains will come from full automation of instrumentation and control (I&C) systems to allow plant operations to come ever closer to material limitations of important components such as superheater headers. “Optimization of I&C is the most cost-effective way to improve plant flexibility and should be a precondition for other measures,” and today, the industry already has access to various process optimization software systems, such as those offered by ABB, Emerson, GE, Siemens, and Uniper, she noted. In the not-so-distant future, fully automated I&Cs could be interconnected to the industrial internet of things, allowing a power plant to incorporate technologies, such as virtual reality to plan outages and simulate plant behavior; augmented reality to support maintenance work; and big data solutions to tap the vast potential of predictive maintenance. ■

—Sonal Patel is a POWER senior associate editor.