O&M

-

O&M

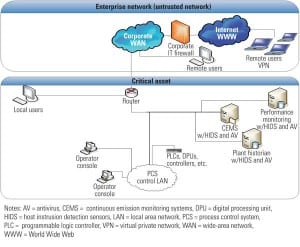

Helping Power Plant Control Systems Achieve NERC CIP Compliance

This guide offers suggestions from a control system engineering perspective for protecting power-generating units that are determined to be critical cyber assets

-

O&M

Best Management Practices for Coal Ash Ponds

The unfortunate coal ash spill at the Tennessee Valley Authority’s (TVA’s) Kingston Fossil Plant that occurred on December 22 has heightened national awareness of the problems associated with utilities’ coal ash surface impoundments if they are not properly maintained.

-

O&M

Reduce Costs with Wireless Instrumentation

New wireless technologies for power plant instrumentation offer significant cost savings when compared to traditional wired networks. The value of this cost savings is especially relevant in the highly competitive power industry, where aging facilities are common and upgrades are an expensive necessity. Modern wireless networks offer a reliable upgrade path that even provides some unexpected benefits when compared to traditional copper networks.

-

O&M

FERC Focuses on Internal Compliance Programs

By now, most electric industry participants are aware of the mandatory reliability standards required by the Energy Policy Act of 2005 and managed by the North American Electric Reliability Corp. (NERC). Bulk-power system users, owners, and operators (known as NERC registered entities) are responsible for complying with the set of standards that are applicable to their operations in their specific region. Compliance is monitored by the NERC regions (Texas Regional Entity, Western Electric Coordinating Council, Reliability First Corp., Midwest Reliability Organization, SERC Reliability Corp., Florida Reliability Coordinating Council, Northeast Power Coordinating Council, and Southwest Power Pool) through spot checks, self-certifications, audits, and investigations.

-

O&M

Preventing Boiler Code Violations Creates a Safer Work Environment

Nearly 10% of boilers and pressure vessels inspected in the second quarter of 2008 were slapped with violations, which means that the violations put workers and equipment in danger, according to a quarterly report released by the National Board of Boiler and Pressure Vessel Inspectors.

-

O&M

Converting a Pump to Use Mechanical Seals

Wear and leakage are common maintenance problems that result in pump discharge pressure dropping below optimum levels and reduced pump efficiency. Converting pumps to mechanical seals eliminates fretting or grooving of the shaft and provides for easier pump maintenance. By converting to mechanical seals, a plant also avoids incurring expenses associated with the replacement of sleeves and shafts.

-

O&M

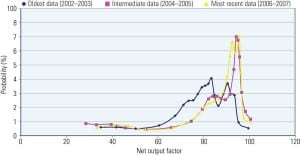

2009 Industry Forecast: Existing Generating Assets Squeezed as New Project Starts Slow

Most forecasting reports concentrate on political or regulatory events to predict future industry trends. Frequently overlooked are the more empirical performance trends of the principal power generation technologies. Solomon & Associates queried its many power plant performance databases and crunched some numbers for us to identify those trends.

-

O&M

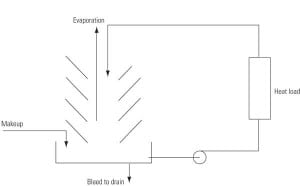

Conserve Water by Improving Cooling Tower Efficiency

Though an abundant supply of freshwater has been taken for granted in many parts of the world, its availability is becoming less certain, even in North America. Water is a valuable resource and commodity that needs to be efficiently managed to minimize waste, reduce energy consumption, and control cost, especially for power generation. The industry must respond by seeking out more efficient ways to use water, such as by implementing water recycling and reuse strategies, especially for critical equipment like cooling towers.

-

O&M

Stopping Natural Gas Leaks

Chances are you have endured the tedious process of removing fuel piping when maintaining just about any gas turbine, especially aero-derivative engines that are usually swapped out rather than repaired in place. One of the most time-consuming jobs after reassembling the fuel piping is checking for leaks at all the flanges. In a large frame-size turbine, that means sealing up to 64 flanges and then removing the seals after the leak testing.

-

O&M

Improving Workforce Connectivity

Wright-Hennepin Cooperative Electric Association (WHCEA) is an electric distribution utility located in Rockford, Minn., that has been serving Wright County and western Hennepin County near Minneapolis with electricity since 1937. WHCEA is a not-for-profit, member-owned energy and service cooperative dedicated to enhancing the quality of life of its members and providing reliable services. Its field operations department consists of 35 fleet members who focus on building and maintaining electric power lines.

-

O&M

Oregon wind turbine loses its bearings

The generator bearings on a wind turbine located in Oregon (Figure 1) first failed in May 2006, only 11 months after the tower was brought on-line. The company that owns and operates the wind farm replaced the bearings and slip rings, but the new bearings failed only five months later. Once again, new bearings and […]

-

O&M

Advanced batteries supply ancillary services

For the power engineer, delivering an instantaneous and consistent power supply can be an elusive goal. Yet without it, grid frequency regulation is impossible. Today, frequency regulation is an ancillary service bought by the hour, the day prior to utilization, and dispensed on an as-needed basis by dispatch communiqués and provided by the ancillary service […]

-

O&M

Innovative Control Strategies Improve Boiler Dynamic Response

The more capable a power-generating unit is of reacting quickly to changes in load demand, the more profitably the unit can be operated. An improvement in load dynamics means that additional control response and capacity can be made available to the power grid. These characteristics are especially in demand in regions where a fast-responding unit can supply energy as ancillary services at a premium price.

-

O&M

Securing continuous mobile data connections

For busy staff in the field, nothing is more frustrating than having laptop computers or smart phones crash due to lost connections when those devices lose wireless coverage. Often, important data is obliterated and workers have to waste precious time reentering the lost information. The irony is that wireless data connections, which are increasingly being […]

-

O&M

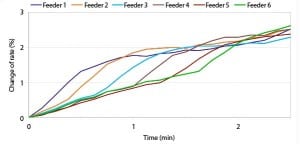

JCP&L’s SCADA-controlled adaptive relay scheme saves 25 SAIDI impact minutes

In 2005, Jersey Central Power & Light (JCP&L), a subsidiary of Akron, Ohio – based FirstEnergy Corp., initiated a project to identify protection system improvements that could be made to proactively combat wind- and lightning-related weather events that create sustained power outages (Figure 2). JCP&L determined that these changes had the potential to improve the […]

-

O&M

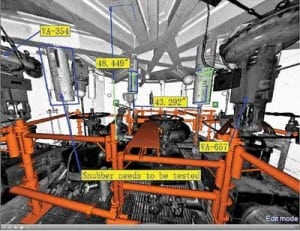

Laser scanning produces 3-D plant database

Advanced computer design tools have merged with high-definition laser camera scan data to produce integrated images that are particularly useful for outage and maintenance planning.

-

O&M

Acceptable alternatives to titanium tubing

As an alternative to titanium, consider highly alloyed stainless steels for your next tubing project.

-

O&M

Scenario training improves emergency response preparedness

A key maxim of the military is "train like you fight, and fight like you train." The same applies to emergency response training, which should be a part of a plant’s routine operation. Don’t risk waiting until an accident occurs to test your response plan. At approximately 8:30 a.m. on a Tuesday morning, the Paducah […]

-

O&M

Managing software life-cycle issues

Software ranges from shrink-wrapped products available “off the shelf” to custom corporate implementations of enterprise systems that require sessions with shrinks to keep everyone sane. Regardless of its complexity, every piece of software a plant uses, or interfaces to, poses critical issues that require life-cycle management. Although functionality has always been the chief specification for software, plants must pay far more attention to long-term quality issues. These two concerns are often at odds with each other.

-

O&M

Repairing low-pressure rotors with cracked blade attachments

An increasing number of low-pressure steam turbines—especially at supercritical fossil units—have experienced stress corrosion cracking in the blade attachment region of their low-pressure rotors. Approaches to solving this problem range from redesign of the attachment and blade replacement to in-situ weld repair. Regardless of the procedure selected, the solution must completely restore the turbine performance while minimizing outage duration.

-

O&M

Entergy’s “big catch”

Entergy christened its Performance Monitoring and Diagnostic Center several years ago to leverage the expertise of its most senior operators and technicians across the company’s entire fleet of plants. The center also makes use of advanced software tools that increase plant availability and reliability by identifying faults before they become major, unplanned outages. The center paid for itself for years to come with a single “big catch” last year.

-

O&M

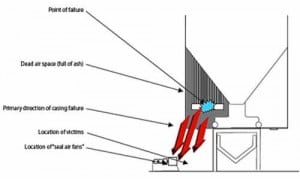

Anatomy of a Boiler Failure—A Different Perspective

The power industry’s operating and maintenance practices were held up to intense regulator and public scrutiny when on November 6, 2007, a Massachusetts power plant’s steam-generating boiler exploded and three men died.

-

O&M

The Low-Down on Low-Alloy Filler Metals

Chromium-molybdenum (chrome-moly) pipe has become a standard in the power generation industry, not only because of its corrosion resistance and high-temperature strength, but also for its cost-effectiveness. In many applications, it is a viable alternative to a more costly stainless steel pipe.

-

O&M

Hill Backing New FERC Powers on Grid Cyber Attacks

Spurred on by a recent audit showing widespread utility noncompliance with voluntary recommendations meant to protect the grid from cyber attacks, key lawmakers have unveiled plans to give the Federal Energy Regulatory Commission (FERC) broad powers to enact new mandatory measures to close vulnerabilities in the U.S. bulk power system to potentially devastating computer-launched assaults.

-

O&M

Put a lid on rising chemical costs

News reports tell us that rapidly growing economies, such as China’s, are importing more oil and raw materials each year, thereby pushing up commodity prices on the world market. One of the side effects of rising commodity prices is considerable increases in the cost of water treatment chemicals. Don’t be tempted to skimp on chemicals to save a buck but risk catastrophic damage. In the words of NASA’s former flight director, Gene Kranz: “Failure is not an option.”

-

O&M

Deaerator degradation: Managing remaining life and component replacement

Proper attention to dissolved oxygen levels in feedwater is fundamental for long-term equipment reliability, especially in a combined-cycle plant. When equipment approaches its design life, proper use of new analytic tools and technical expertise can identify impending corrosion and erosion problems and provide you with an estimate of remaining equipment life.

-

O&M

Focus on O&M (September 2008)

Tackling substandard water sources / Control abrasive wear in scrubber piping / Sensors and final control elements

-

O&M

Focus on O&M (August 2008)

Assess your cooling tower’s condition / Proper technique for vertical-up stick welding / Move material with a sonic horn

-

O&M

Condensate polishers add operating reliability and flexibility

Many of today’s advanced steam generators favor either an all-volatile treatment or oxygenated treatment chemistry program, both of which require strict maintenance of an ultra-pure boiler feedwater or condensate system. Those requirements are many times at odds with the lower-quality water sources, such as graywater, available for plant makeup and cooling water. Adding a condensate polisher can be a simple, cost-effective solution.

-

O&M

Field application of compressor coatings saves big dollars

Over time, turbine compressors and other driven compressors suffer from corrosion, oxidation, and, in many cases, severe fouling, which in turn can cause in-service breakdown and premature overhaul. Today’s innovative protective coatings can be applied on-site to rotors and individual components to replicate the surface finish, corrosion resistance, and antifouling properties of new components.