The Theory and Application of Acoustic Cleaners

Sonic sootblowers and acoustic cleaners were once thought to be a last-chance alternative to difficult ash build-up problems. However, the technology has proven to be effective over years of service in multiple applications, and the equipment is now seen as a first-choice cleaning technique that saves money, improves efficiency, and reduces damage to critical components.

Did you know there is a simple sonic sound device that can remove process bottlenecks, optimize performance, maximize production output, and improve thermal efficiency? It’s not a theory, it’s a proven technique being used every single day in a range of power generation and dry processing plants in more than 70 countries worldwide.

This innovative technology is put to work in acoustic cleaners and sonic sootblowers. A few seconds of “sounding” at periodic intervals is all that is required to improve thermal conductivity in boilers, economizers, air heaters, and more; prevent material build up within silos, fans, filters, cyclones, electrostatic precipitators (ESPs), and selective catalytic reduction (SCR) systems; maximize material flow in silos, hoppers, and ductwork; eliminate unscheduled plant shutdowns in fans and filters; and reduce opacity spikes from ESPs and filters. Acoustic cleaners are employed wherever ash, powders, or granular materials are processed, generated, stored, or transported.

So, what exactly are sonic sound waves created by acoustic cleaners and how do they work? Sound can best be described as the passage of pressure fluctuations through a medium by means of a vibrating source. It is these pressure fluctuations and the resulting “compression” and “rarefaction” cycles that are used by acoustic cleaners to move powders by breaking particle bonds.

The ear does not actually hear sound. It is a pressure sensitive mechanism that detects very rapid pressure fluctuations, and it is these very rapid pressure fluctuations that cause dry material to de-bond from both adjoining particles and from structures.

In the case of an acoustic cleaner, the wave generator creates the “base” tone, and the variety of bell sections amplify and convert this into a particular fundamental frequency. Within the Primasonics range, there are six selected frequencies ranging from 60 Hz to 420 Hz. All that is required to “power” the titanium diaphragm within the wave generator is normal plant compressed air at a pressure of 5 bar to 6 bar.

So, what do these high-energy, low-frequency sound waves actually do? They produce very rapid pressure fluctuations (up to 840 times per second), which break the cohesion bonds between one particle and another, and between each particle and the structure to which they are adhered to. Once these bonds have been broken, the particles, such as cement powder or fly ash, are removed either by gravity or in the gas stream.

Another common question is: Will an acoustic cleaner cause any damage to the structure? The answer is no. The wave generator and exponential bell shape of a Primasonics acoustic cleaner has been very carefully calculated to ensure that the unit has a very high acoustic impedance. Just as an electrical coupling between components is only efficient if impedance is similar, so too with acoustics.

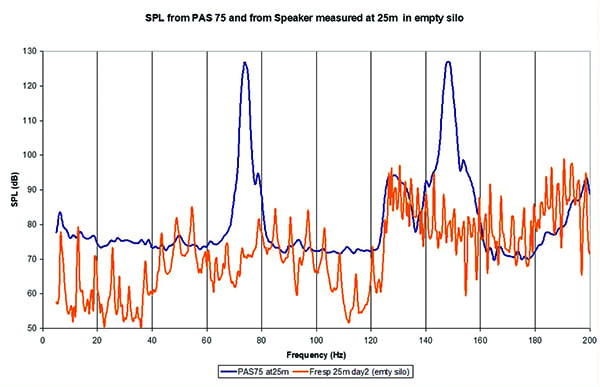

Primasonics, working with the Acoustic Research unit at the University of Liverpool in the UK, has conducted many laboratory and on-site tests to ensure that coupling does not take place between the acoustic cleaner and structures. Figure 1 shows the sound pressure level (shown as the two large peaks in the dark blue line) caused by a PAS75 acoustic cleaner and the vibration levels of the structure (shown by the orange line). It can be seen that there is no corresponding increase in vibration at the horn’s fundamental frequency of 75 Hz or at harmonic frequencies. This particular test took place in a large steel flour silo where an accelerometer measured the vibration on the silo wall.

|

|

1. This graph shows the sound pressure level caused by a PAS75 acoustic cleaner (dark blue line) and the vibration levels of the structure (orange line). There is no corresponding increase in the structure vibration at the horn’s fundamental frequency of 75 Hz or at harmonic frequencies, which means no fear of damage to the structure. Courtesy: Primasonics |

Benefits of Acoustic Cleaners

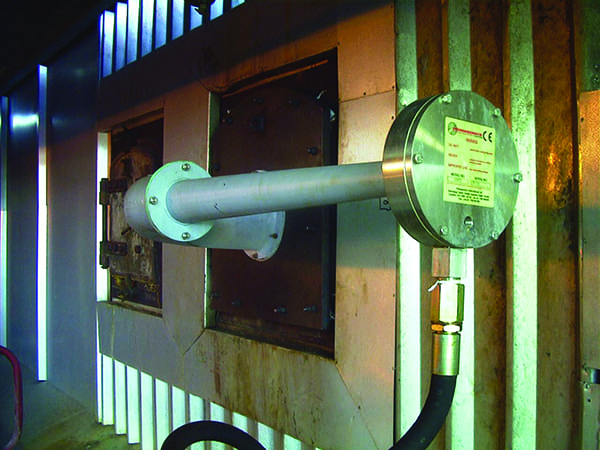

Acoustic cleaners have become the first choice to prevent ash build up from occurring in all sections of the power generation plant, including boilers, superheaters, economizers (Figure 2), and air heaters. The main advantages sonic sootblowers have over steam sootblowers are:

|

|

2. Acoustic cleaners can be used in a variety of applications. This image shows a cleaner installed on a power plant economizer. Courtesy: Primasonics |

■ Price/Operating and Maintenance Costs. The sonic sootblower is cheaper to purchase and install. It is considerably more economical to operate and has virtually no maintenance costs.

■ Physical Damage/Corrosion and Erosion. Sonic sootblowers will not cause any physical damage or wear to tube bundles or boiler structures. They operate at frequencies very much higher than the resonance frequency of steel, ceramic linings, and concrete, and are therefore guaranteed not to cause any vibrational damage to vessels, structures, or tube bundles. Also, because they do not use any high-pressure steam or water, they will not cause corrosion or erosion problems and are eco-friendly.

■ Cleaning Efficiency. Because sonic sootblowers use powerful sonic sound waves—waves that travel at a speed of 344 meters per second and in a 360-degree radius—the entire circumference of the tubes and internal structure can be easily reached, instead of just the leading edge of the tubes as with a steam sootblower. A periodic sonic sounding is all that is required to achieve these effects, typically 5 to 10 seconds every 6 to 12 minutes.

Honeycomb catalyst blocks in SCR systems are often blinded and blocked due to solid particle build up. Acoustic cleaners are used to ensure the particles are excited and can be carried with the gas stream to a suitable filtration or ESP system. A partially blocked catalyst layer can disrupt flow, forcing all the gases through a small number of catalyst blocks, which reduces the effectiveness of the unit. Acoustic cleaners are now recognized as the most-efficient and cost-effective means to ensure that a SCR unit continually operates to its maximum efficiency.

Typical Acoustic Cleaner and Sonic Sootblower Installations

Acoustic cleaners and sonic sootblowers can be used in a variety of power plant applications.

Silos and Hoppers. The three main problems that occur in silos and hoppers are bridging, ratholing, and cross contamination.

Bridging is caused when the design of the hopper section has insufficient angle of repose, side walls with excessive frictional properties, or an insufficiently sized outlet for the material being contained. Consequently, these problems can become severe if a silo is used for materials different than it was designed for either through process or plant layout changes over time.

To combat bridging, an acoustic cleaner is mounted just above the outlet. When it sounds, single particles and clusters of particles move at different speeds, therefore, bridges are collapsed and material flow is restored. Once the acoustic cleaner has ceased to sound, new bridges and arches will begin to form. To counter this, the sounding may be controlled in one of two ways: simply on a timer device, typically set for a few seconds every few minutes, or automatically via a flow sensor downstream of the outlet or triggered by load cells.

Ratholing, or funnel flow, occurs when an insufficient angle of repose is used in the silo for the contained material. This usually occurs with material that displays mechanical interlocking properties or very quickly bonds without compaction, for example, because of heat or by means of solvent evaporation. To defeat ratholing, acoustic cleaners with a long wave length are placed on the top of the silo, usually through an existing manhole or inspection hatch.

Considering a full silo that is prone to ratholing being slowly emptied, it’s easy to imagine the central core of the material lowering a small amount while an outer ring close to the side walls remains at the same height. Without acoustic cleaning, this process would continue until eventually the central core is discharged and the outer ring is left adhering to the side walls. In this case, a decision has to be made whether to remove the silo from active process lines so offline cleaning can take place or refill the silo and risk lower control over both the quantity and quality of product, as older adhered material will mix with the new material coming in.

Using acoustic cleaners, once they sound, the bonds holding the outer ring will collapse and this will form a flat surface along the top of the material in the silo. This pattern is repeated as the silo empties, even if the silo is refilled before complete discharge has taken place. This now allows a first-in, first-out mass flow pattern.

In the example of a pre-packing hopper or weigh hopper, sometimes not all the material is discharged before the next batch enters the hopper. This can cause product cross contamination, which can lead to quality control problems. The reasons for material failing to discharge from hoppers are similar to those already mentioned, but in pre-packing hoppers, weigh hoppers, or similar batch-filled vessels, an additional problem occurs when material hits or comes in contact with colder side walls and moisture precipitates from the bulk material onto the side wall. This moisture forms a meniscus between the side wall and the particles, which holds the powder in place, so that even after discharge, a thin layer or powder remains. In this instance, if the acoustic cleaner is activated when the bin is being emptied, the alternate compressive and rarefactional forces break the surface tension of the moisture and allow the material to flow out, leaving the vessel completely empty.

Induced Draft (ID) Fans. Acoustic cleaners are being used for cleaning fans in a variety of industries. Advantages include:

- ■ A uniform cleaning pattern.

- ■ Cleaning inaccessible parts of the fan.

- ■ Eliminating out-of-balance fan conditions.

- ■ Eliminating unscheduled fan shutdown.

Acoustic cleaners can be used to prevent build up on ID fans (Figure 3). The acoustic cleaners are operated intermittently and controlled by a simple timer or connected to vibration sensors as part of a monitored preventative maintenance system. Major savings can be achieved by eliminating unplanned shutdowns caused by fan imbalance.

|

|

3. This image shows an acoustic cleaner installed on an induced draft fan. Courtesy: Primasonics |

Baghouse Filters. Acoustic cleaners are being used on reverse air, pulse jet, and shaker units. The acoustic cleaners are effective in reducing pressure drop across the collection surface, increasing bag life, and preventing hopper pluggage. They can be very beneficial to filter bag life and lead to significant reduction in compressed air usage. Acoustic cleaners are generally mounted in the hopper section below filter bags where they can also help to clean frame works and keep the hopper sections free from build-up (Figure 4).

|

|

4. This image shows an acoustic cleaner installed on a fabric filter. Courtesy: Primasonics |

By the sonic cleaning action of acoustic cleaners, bags do not suffer the same shocks and weave deterioration caused by reverse pulsing and can last up to 80% longer than bags subject to reverse pulsing. Acoustic cleaning provides the ability to turn off or reduce the frequency of reverse pulsing and helps save compressed air, as significant volumes are expended within filter systems. Acoustic cleaners help to maintain clean and efficient filters, reducing differential pressure and avoiding any output particulate spiking.

ESPs. Acoustic cleaners are proving invaluable in ESP applications (Figure 5), bringing advantages such as superior cleaning, elimination of excess build-up problems, and increased precipitator efficiency. Acoustic Cleaners can provide many benefits for the effective cleaning of turning vanes, distribution plates, collecting plates, and electrode wires. Acoustic cleaners have been employed to either replace or assist mechanical rapping systems and provide superior cleaning through the precipitator.

|

|

5. This image shows a cleaner installed on an electrostatic precipitator. Courtesy: Primasonics |

In addition, they prevent particulate build up in the under hoppers, which can result in opacity spiking. Other advantages include cleaning of walls, roofs, and steelwork with no mechanical stress or damage to the vessel or equipment; the elimination of excess build-up problems; increased up-time; and increased precipitator efficiency.

Ducting. Acoustic cleaners have proven to be effective in eliminating unwanted build up in ducting, thus avoiding unscheduled plant shutdown for manual cleaning in some situations.

New Cleaning Developments

The Macro Sonics Acoustic Cleaner (30 Hz) was designed for the rapid cleaning of ships’ holds and also for large boiler cleaning where there is only a single entry point. Its design also ensures that powerful macro-sonic sound waves do not cause any vibrational damage to structures.

The Prima Touch system offers a way to remotely report on the operational efficiency of any acoustic cleaner by measuring two important characteristics of each unit’s performance. Firstly, it measures the compressed air pressure and provides a 24-volt direct current (DC) output. Secondly, it uses an accelerometer to measure vibration changes on the back plate of the wave generator, which would indicate either a blocked wave generator or wear on the titanium diaphragm. These two streams of information can be transmitted to any of three locations: a local programable logic controller, which can also control the sounding pattern; the plant’s control room or manager’s screen; or the Primasonics Monitoring Service, which will routinely report on the monitoring of each acoustic cleaner. The monitoring service is offered to customers as an add-on option.

Sonic sound waves in the form of acoustic cleaners were once seen as more of an art than a science. However, due largely to Primasonics’ 20 years of continuous research and development linked to installations in more than 70 countries, and through the company’s engineering and scientific skills, dry processing, storage, and power generation plants can now benefit from proven technology by installing acoustic cleaners and sonic sootblowers.

—Donald F. Cameron is managing director with Primasonics International Ltd.