Improve Baghouse Performance with Custom Filtration Media

Dust collection plays a vital role for safe and efficient power plant operation. There are a number of dust collection options available to plant designers, and baghouses have gained wide acceptance.

The baghouse has high collection efficiency that is relatively constant with load and fluctuating fuel properties. Unlike an electrostatic precipitator (ESP), whose performance is dependent on inlet dust burden and fly ash resistivity, a baghouse can tolerate a reasonable increase in gas flow and dust inlet burden for short periods without affecting dust emissions. A key to efficient and long-term baghouse operation is proper selection of the fibers used in the filter media.

Baghouse Design Basics

The principles of baghouse operation may be straightforward, but the design of a baghouse is complicated. Baghouse designers must carefully evaluate volumetric gas flow and velocity, static pressure drop, and gas-to-cloth ratio, in actual cubic feet per minute per square foot of filtration area (acfm/ft 2), to obtain optimum removal of flue gas particulates—from submicron to several hundred microns in diameter—with collection efficiency in excess of 99.9%. Fuel combustion products, operating temperature, dust loading, physical characteristics of the particulates, and the dew point of any condensable in the gas stream also play a vital role in the choice of the fabric material and bag design, particularly in coal-fired plants using coal that produces flue gas with high dust content.

Particulate capture occurs best on the surface of the filter media of fabric filter units, as the gas passes through the filter fabric and the clean gas is vented to atmosphere. Exhaust gas is drawn through the filter media forming a dust layer on the surface of the fabric media. When the prescribed pressure drop is reached, the filter bags are cleaned, either online or offline. Particulates captured on the surface of the filter fabric are typically separated by a short upstream burst of high-pressure air to remove the dust particulates from the filter media surface. The particulates are subsequently collected in a hopper found at the bottom of the baghouse enclosure for disposal.

Whenever the dust collection occurs through the entire section of the filter media, baghouses experience premature pressure drop and an increase in emissions. It is therefore paramount to keep the particulate capture on the surface of the filter media (we call it surface-oriented filtration).

Filter Media Fundamentals

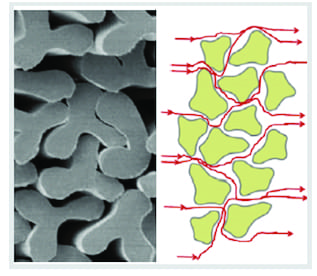

P84 fiber is unique among all available filtration fibers. It is the only fiber produced with an irregular, multi-lobed shape. Each fiber has its own unique shape and is formed naturally as a part of the production process. The irregularity of the P84 fiber cross-section ensures the filter material when charged with dust maintains a high porosity. A porous dust cake with a high surface area ensures a high contact between the gas molecules and the reagent as the flue gas passes through the dust cake. In addition, that allows differential pressure to remain lower than with traditional round section fibers (Figure 1).

|

|

1. A P84 fiber cross-section is shown at left. An example of the path gas might take passing through the P84 structure is shown at right. Dust particles are removed from the gas as it navigates through the tight clearances. P84 fiber is purchased by needle felt producers who process it into filter media used in baghouses. Courtesy: Evonik |

A critical aspect of the filter material used in power plant baghouses is also the fiber surface area. P84 fibers, with their high cross-section irregularity, have larger surface area than fine circular fibers for a given filter volume, so the travel path through irregularly shaped filter media is also more complex, and is instrumental in the formation of a stable yet porous dust cake, particularly during cleaning.

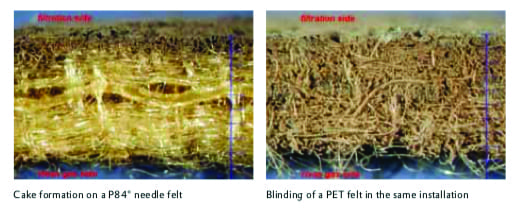

P84 fiber filter media also prevent the penetration of fine dust particles deep into the needle felt due to its excellent filtration properties. The unique multi-lobed profile of P84 fibers ensures that even fine particles are collected and no dust penetrates the needle felt even at very high dust loads typically found in many coal-fired plants (Figure 2). This has important benefits in terms of low particulate emissions, low pressure drop across the baghouse, low compressed air pulsing volume and rate, and increased capacity to deal with a high dust loading.

|

|

2. Filters used in coal-fired boilers are usually constructed with non-woven media. The exhaust gas passed through the media from top to bottom in the photos. On the left, dust is captured on P84’s irregular, multi-lobed shaped surface forming a porous permanent dust cake layer. A typical felt media, shown on the right, is totally blinded by dust causing excess pressure drop and particulate carryover. Courtesy: Evonik |

The most important dust collection activity takes place in the permanent dust cake formed on the surface layer. The dust cake formed by multi-lobed fibers is stable and part of it remains attached to the felt during the cleaning. Without a permanent dust cake, small particles can pass through. More importantly, a stable, porous dust cake is also required to prevent blinding of the felt and excess emissions. A standard 2.2 dtex P84 fiber has 65% more surface area than a comparable round fiber size. This increased surface area allows much more dust to attach to the surface area when compared to a round fiber, keeping the felt clean over time. If small particle sizes or strict emission limits are a concern, finer P84 fibers with even more surface area are available.

Low-velocity contour zones are created when flue gases pass by P84-based felt fibers. P84 fibers provide low- and zero-velocity zones, allowing dust to slow down and collect on the fiber surface. These zones are quite extensive compared to round fibers. The structure of the filter media is transferred to the structure of the dust cake and the dust cake formed by the P84 multi-lobed fibers is irregular and porous. The flow-lines of flue gases are affected to a lesser extent if compared to the round fibers dust cake.

The air-to-cloth ratio (cfm/ft 2) is also an important factor in bag performance. Membrane bags are limited to 3.3:1 and round fiber bags are limited to 3.9:1. P84 bags can tolerate air-to-cloth ratios of 4.6:1 providing 20% to 30% more capacity.

Successful P84 Baghouse Retrofits

Three case studies illustrate the operating cost and reliability advantages of using P84 in baghouses installed on coal-fired power plants. They include Nebraska Public Power District’s 225-MW Sheldon Station in Hallam, Nebraska; and Eskom’s Arnot (2,100 MW) and Duvha (3,600 MW) power plants, both in Mpumalanga, South Africa.

The Sheldon Station (Figure 3) consists of two Babcock & Wilcox cyclone boilers burning Powder River Basin coal. Baghouses for each unit were constructed in 1999 and 2000, respectively, replacing ESPs. The bags are built to operate at 310F with a 3.5:1 cfm/ft 2 gas-to-cloth ratio. The dust loading is 0.97 grains per actual cubic foot (gr/acf) at the inlet and 0.005 gr/acf at the outlet.

|

|

3. The Sheldon Station in Nebraska features two Babcock & Wilcox cyclone boilers burning Powder River Basin coal. The baghouses for the plant’s two units were built in 1999 and 2000, replacing electrostatic precipitators. The plant reports significant cost savings from its use of P84 filter material. Courtesy: Evonik |

Several alternative media configurations were evaluated during the initial startup of the baghouses. After six months of testing, P84 and P84 scrim were determined to be the most cost-effective configuration based on the plant’s particle size distribution, temperature at the bag, and level of acid products in the exhaust gas. PPS (polyphenylene sulfide) filter bags were among those tested but filter bag life was only 24 months. Since the testing, the P84 bag life has averaged five years for Unit 1 and seven years for Unit 2 over the past 17 years. Over the operating life of the bags, average system pressure drop of 6 inches water column has been maintained with seven cleaning pulses of compressed air per hour.

Sheldon Station reports significant cost savings using P84 filter material in its baghouses over the past 17 years. The cost savings fall into two categories: increased energy sales and decreased replacement bag cost. Reduced pressure drop through the P84 media reduced ancillary loads, principally reducing induced draft fan power by 87,000 MWh, saving $6.1 million. Extended bag life when using P84 media also reduced the cost of replacement bags by $1.5 million.

South Africa’s Eskom owns and operates more than 40 GW of installed capacity and is the largest utility in Africa. The Arnot Power Station consists of six nominally rated 350-MW coal-fired units originally installed between 1968 and 1975. The station burns a relatively poor South African bituminous coal composed of 25% ash with a heating value of 26 to 27 megajoules per kilogram (MJ/kg). The plant has posted 92.07% average availability over the past three years.

Arnot Power Station was upgraded from ESPs to baghouses in the 1990s as part of a project to increase plant capacity. Phase 1 added baghouses to Boilers 4, 5, and 6 (each containing 11,000 bags) with a maximum gas-to-cloth ratio of 3.5 cfm/ft 2. Phase 2 added baghouses (each with 14,000 bags) to the remaining three boilers with a maximum gas-to-cloth ration of 2.8 cfm/ft 2.

Potential baghouse suppliers were invited to demonstrate their collection technology with a pilot project. PPS bags were initially specified due to the high temperature gradient after the air preheater. However, during operation of the pilot plants, the suppliers learned that the specified baghouse pressure drop could not be maintained. The flue gas contained fine dust with a smooth surface that characterizes South African coal.

This dust had penetrated the PPS filter material down to the scrim, which led to depth filtration and bag blinding. The problem was solved when a fabric supplier proposed using a P84 filter media with a fine-fiber P84 cap on top of the standard PPS substrate. The composite bags were then installed on Boilers 4, 5, and 6, followed by the remaining boilers as part of Phase 2 project. Since installation, filter bag life has ranged from 30,000 to 52,000 hours. The guaranteed filter life was 28,000 hours.

Eskom’s Duvha Power Station (Figure 4) consists of six 600-MW units with once-through Benson boilers, built between 1975 and 1984. In 1993, Duvha was the first power station in the world to be retrofitted with pulse jet fabric filters, which were added to the first three of its units. Each baghouse has 26,928 bags, each with a 4.0 cfm/ft 2 gas-to-cloth ratio. The coal burned is similar to that burned by Arnot Power Station, although with 30% ash. The filter bags used low temperature PAN (polyacrylonitrile) material with an upstream air attemperation system on each unit. The bag life was guaranteed for 28,000 hours.

|

|

4. The Duvha Power Station in South Africa has six 600-MW units. The station in 1993 became the first in the world to be retrofitted with pulse jet fabric filters, which were added to the first three units at the plant. Courtesy: Eskom |

Premature failure of the PAN bags began after 8,000 hours of operation due to acid degradation. The cause was determined to be the acid dew point of the 3% sulfur heavy oil used for boiler startup. Switching to a light oil reduced the rate of degradation but did require the pressure drop setpoint to be adjusted from 0.9 kilopascal (kPa) upward to 1.4 kPa. The majority of the PAN bags lasted about 18,500 hours, but some failed with less than 5,000 hours.

Because Duvha was Eskom’s first station with bag filters and Eskom was simultaneously occupied with fabric filter installation programs at other stations (including Arnot), the experience forced the company to establish an in-house capability of understanding polymers and filtration media, which led to the creation of a full-fledged textile laboratory. This eventually resulted in a switch to PPS bags, which extended bag life to 22,000 to 24,000 hours, although many bag failures after 15,000 hours of operation were experienced.

The PPS and PAN failure modes occurred because of the limited alkaline capacity of the coal dust to neutralize the sulfuric acid formed in the flue gas when cooled below the acid dewpoint. In addition, the attemperation air that was added to the air ducts upstream of each baghouse created localized SO 3 condensation zones. The sulfuric acid formed from these two sources was not being totally neutralized by the alkaline dust cake, and attacked the PAN and PPS filter fibers.

Once Eskom understood that blinding was the predominant bag failure mechanism across the various plants, it embarked on research aimed at retarding the blinding rate, hence extending bag life and performance. After a number of trials, and in collaborative effort with fiber and fabric suppliers (including the full-scale evaluation at Arnot), the solution chosen was to install composite bags with a P84 cap applied to a PPS substrate, which ensured the formation of a porous and stable dust cake that promoted complete acid neutralization and surface filtration. The service life of the latest sets of P84+PPS bags is more than 36,000 hours, with less than 10% failure of the 27,000 bags installed per unit.

The switch to P84+PPS bags has resulted in significant savings for Eskom, about $500,000 annually. That figure does not include reduced costs for labor, or production losses, which can be significant. In one instance, prior to the switch to P84+PPS bags, two boilers were shuttered for four months waiting for replacement bags.

User-led collaboration with suppliers has led to a proliferation of composite fabric constructions with fine denier surface layers, not only by Eskom, but also other utilities. ■

—Nathan Schindler is technical sales manager for Evonik Corp.