Fluidized Bed Steam Reforming Technology Reduces Volume of Radioactive Waste

A patented Fluidized Bed Steam Reforming (FBSR) technology uses superheated steam—instead of an open flame—and mineralizing additives to treat and immobilize radionuclides in a water-insoluble matrix. Results show a 6:1 average volume reduction for ion-exchange resins, which allows disposal without entering into higher, more-restrictive and expensive waste classifications. Since initial pilot studies beginning in 1997, FBSR technology has been deployed in the U.S., Japan, and France.

The nuclear industry annually produces voluminous amounts of radioactively contaminated ion-exchange resins (IERs) comprised of organic material, usually a styrene polymer containing sulfonic acid and amine groups. The resins, for example, are used to concentrate and remove activation, corrosion, and fission-product radionuclides from nuclear plant liquid waste streams. Traditional high-temperature, flame-induced combustion treatment processes (such as incineration) form and release sulfur and nitrogen oxides, including vaporization of cesium-137, requiring high-performance filtering systems. The retained radioactively contaminated fly ash is solidified and containerized according to transportation and low-level radioactive waste (LLRW) disposal regulations.

Following a number of pilot studies beginning in 1997, Studsvik developed and patented a non-incineration Fluidized Bed Steam Reforming (FBSR) technology—that uses steam—to treat a variety of LLRWs containing high organic, nitrate, nitrite, solids, and heavy-metal content, while producing a dry, stable, granular, final waste form. Because there is no flame present in the primary waste treatment vessel, the treatment process is not considered incineration. Additional advantages include no liquid effluents other than water vapor and Clean Air Act-compliant off-gas emissions.

Treating Low-Level Radioactive Wastes

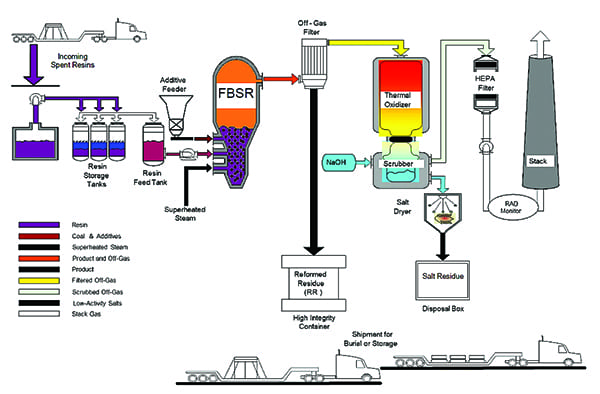

POWER interviewed Adam Foster, PE, head of engineering services with Studsvik Inc., who is based in Atlanta, Georgia, for details about the FBSR technology. One location that utilizes FBSR technology is the Erwin Resin Solutions (ERS) Facility located in Erwin, Tennessee (Figure 1). It is a production-scale, shielded facility that houses equipment for handling and converting LLRW into an inert, stable, and volume-reduced final waste form.

Studsvik’s FBSR waste decomposition process uses steam pyrolysis as an alternative to incineration and other traditional thermal treatment methods. This yields a solid, inert, stable, and substantially smaller volume waste matrix, while meeting all federal and state radioactive waste processing laws, codes, and standards.

Foster described how spent IERs from commercial nuclear plants are shipped to the ERS and transferred as a water/IER slurry to waste holding tanks located in shielded vaults. After the IERs settle in the holding tanks, excess water is decanted from the top.

Mixing the settled IERs creates a homogenous mixture, which is transferred to a metering tank to start the FBSR process. A mineralizing additive is mixed with the IER as it is metered/fed into the FBSR vessel to prevent agglomerations from forming in the fluidized bed. Other process additives, such as mineralizing clay, may be added depending on the type/composition of the waste and the desired final waste matrix durability characteristics, which include water solubility and leach resistance.

Low-pressure superheated steam is introduced through gas nozzles, creating a fluidized bed at the FBSR vessel bottom with a gas-phase freeboard in the vessel top. In the fluidized bed, the waste feed is instantly dried, and the large active surface of dried organics readily pyrolyze in the reducing environment, resulting in the destruction/volatization of organics into carbon dioxide and water vapor with small amounts of elemental carbon, methane, carbon monoxide, and hydrogen.

Granular carbon is added directly to the FBSR where a portion is oxidized to produce necessary process energy. The carbon also serves as the “reductant,” facilitating the chemically reducing environment in which the desired reactions occur inside the fluidized bed, including alkali and radionuclide mineralization, and formation of metal oxides, carbonate salts, carbon dioxide, inorganic particulates, and process gas.

The remaining inorganic waste residues, also known as reformed residue (RR), are carried (elutriate) out of the FBSR vessel with the process gases. The amounts are directly related to waste composition, additives, and operating conditions. The RR solids contain greater than 99.99% of the incoming radionuclides and essentially all other inorganics present in the original waste feed. High-temperature ceramic filters inhibit RR solids from entering the gas oxidation system, preventing fouling or an altered final waste matrix chemical morphology.

The filtered process gas from the high-temperature filters is mixed with air upon entering a direct-fired thermal oxidizer, converting all residual carbon monoxide, volatile organics, and traces of hydrogen into carbon dioxide and water vapor. Hot gases from the thermal oxidizer pass through a venturi and into a scrubber containing a pH-controlled sodium hydroxide solution. This system cools the hot gases to about 80C almost instantaneously, and the sodium hydroxide solution absorbs and neutralizes acid gases. The salt solution is pumped to a spray dryer where it is atomized, dried, and collected for burial as LLRW.

The clean, moisture-laden process off-gases exit the scrubber, and excess moisture is condensed for reuse as scrubber system makeup water. The condenser acts as the process heat sink, controlling the water balance in the scrubber system. An electrical heater then heats the off-gases to 120–140C to ensure that the off-gas is dry and free of moisture prior to entering the high-efficiency particulate air (HEPA) filters. The gases co-mingle with the building ventilation airflow prior to flowing through the HEPA filter bank, a vent blower, and being released through a monitored ventilation stack. The high-level IER-FBSR process flowsheet is shown in Figure 2.

Monitoring and Final Waste Matrices

A continuous radiation monitoring system measures and documents any trace radionuclides that may pass through the stack. The system includes alpha, beta, gamma, iodine, carbon-14 (C-14), and tritium (H-3) samplers and detectors. Testing has shown that more than 99.99% of received radioactivity is retained in the RR. Carbon-14 and tritium—two major concerns for shallow land burial due to the potential for radionuclide migration—are effectively removed from the RR. If needed, C-14 and tritium capturing systems can be utilized for the retention of these radionuclides. Iron, nickel, cobalt, and cesium are the primary radioactive RR constituents, and proportioned according to the makeup of the IER received.

The final waste matrices consist of metal oxides, carbonate salts, or alkali-aluminosilicate (NAS) minerals, depending on the mineralizing additives and type of waste/composition. Metal oxides form iron-based spinels, that is, a class of minerals arranged in a cubic, close-packed lattice, which are water insoluble. Carbonate salts are mostly soluble in water, while NAS minerals provide high leach resistance. If an NAS final waste form is desired, the aluminosilicate additive must be used.

As a granular product, the FBSR NAS mineral waste matrix has been shown to be more durable than glass during testing originally conducted using ASTM C-1285-02, “Standard Test Methods for Determining Chemical Durability of Nuclear, Hazardous, and Mixed Waste Glasses and Multiphase Glass Ceramics: The Product Consistency Test (PCT),” and during subsequent performance assessment modeling.

LLRW Volume Reduction Achieved

In the U.S., current LLRW disposal regulations are based on long-lived and short-lived radionuclide concentrations (curies/m3), which ultimately determines the waste classification, such as Class A, B, C, or Greater than Class C. The waste form must meet rigorous requirements to ensure stability after disposal (protection against inadvertent intrusion). Higher waste classifications increase disposal costs and limit disposal options, such as shallow land burial. By using FBSR technology, results show a 6:1 average volume reduction (VR) for ion-exchange resins, with anion resin treatment yielding VR as high as 30:1 while heavily fouled cation resin treatment can be as low as 3:1. The VR generally doesn’t force entry into a higher, more-restrictive and expensive waste classification, such as from Class B to Class C.

From a chemical perspective, Foster pointed to five factors that affect the maximum achievable volume reduction. They are:

- ■ The inorganic content of the waste.

- ■ The amount of mineralizing additive required.

- ■ The ash content of the additives.

- ■ The amount of coal fines that collect with the solid products.

- ■ And to a smaller extent, the carryover of small, sized, fluidized-bed media, which results from media attrition during operation.

Waste streams with high solids loading or high concentrations of inorganic materials result in lower VRs.

The initial proof-of-process test program concurrent with the qualification test program was conducted in 1997 at the Hazen Research Inc. facility in Golden, Colorado. Since then, FBSR technology has been deployed in the U.S., Japan, and France. Several field testing demonstrations have been conducted, including at the following locations:

- ■ Permanent installation for treating sodium-bearing waste stored in underground tanks at the Idaho National Laboratory, Idaho Falls, Idaho.

- ■ Engineering scale demonstration (ESD) for treating processed organic tank wastes, producing a water-soluble, granular, carbonate-based mineral product at the Savannah River facility in Aiken, South Carolina.

- ■ ESD for treating various Hanford tank wastes at the Hanford Site in Richland, Washington.

- ■ ESD for treating liquid nitrate waste and solid organic material in Osaka, Japan.

- ■ Initial procurement for fabrication of a permanent installation for treating low-level radioactive liquid nitrate wastes in Narbonne, France.

Through testing and demonstration, FBSR technology has proven to be a very beneficial radioactive waste volume reduction process. ■

—James M. Hylko ([email protected]) specializes in safety, quality, and emergency management issues and is a frequent contributor to POWER.