Developing a Solution for Utility-Scale Storage

|

A Canadian company is using its proprietary technology, known as A-CAES, to provide a long-duration, cost-effective way for energy storage to provide power for hours at a time.

Long-duration energy storage is seen as a key technology to support a low-carbon power grid. Storage is particularly important as more intermittent renewable energy such as wind and solar power comes online.

The challenge has been implementing a grid-scale storage technology. Batteries have proven adept at providing power for short intervals; a long-duration solution that can provide power for several hours, and is cost-effective, has been elusive.

Support for solving the long-duration problem is increasing, though, as more countries adopt renewable energy goals and work to integrate renewables onto the grid. Storage is key to providing reliable power as baseload electricity units are retired, so many groups, including government agencies, utilities, and technology providers are working to find solutions.

Hydrostor, a private company founded in 2010 and based in Toronto, Canada, is one of those groups. The company calls itself “the world’s leading developer of utility-scale energy storage facilities,” and is using its proprietary Advanced Compressed Air Energy Storage, or A-CAES, technology and purpose-built underground storage caverns to provide a long-duration solution (see sidebar).

|

The A-CAES Process There are four steps in the Advanced Compressed Air Energy Storage (A-CAES) process. 1. Compress Air Using Electricity. Off-peak or surplus electricity from the grid or a renewable source is used to operate a compressor that produces heated compressed air. 2. Capture Heat in a Thermal Store. Heat is extracted from the air stream and stored inside a proprietary thermal store. This adiabatic process increases overall efficiency and eliminates the need for fossil fuels during operation. 3. Store Compressed Air. Air is stored in a purpose-built air storage cavern where hydrostatic compensation is used to maintain the system at a constant pressure during operation. 4. Convert Compressed Air to Electricity. Hydrostatic pressure forces air to the surface where it is recombined with the stored heat and expanded through a turbine to generate electricity on demand. |

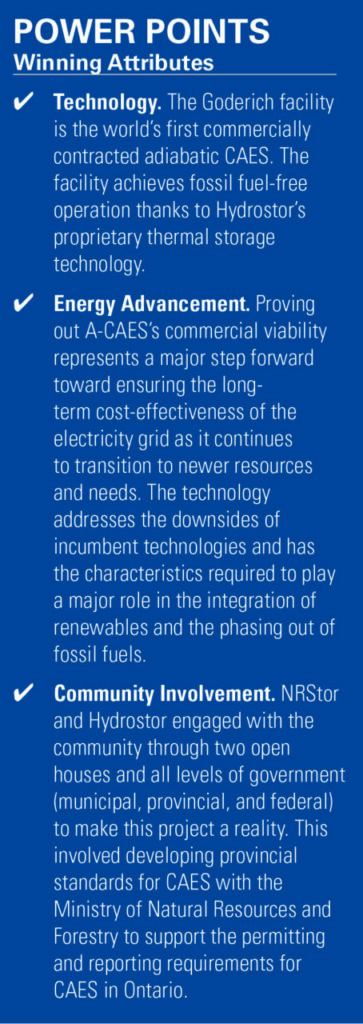

Hydrostor’s Goderich facility in Ontario was officially inaugurated in November 2019 (Figure 1), two years after construction began, and began commercial operations for the province’s Independent Electricity System Operator (IESO) in August 2020. It’s recognized as the world’s first commercially contracted A-CAES facility, working with Ontario’s IESO for peaking capacity, ancillary services, and full participation in the merchant energy market to support grid reliability. The plant uses no fuel, produces zero greenhouse gas emissions, and according to Hydrostor, “helps enable a cleaner, more affordable, and more flexible electricity grid.”

“We’re proud to complete this important commercialization milestone for Advanced Compressed Air Energy Storage, and deliver the significant benefits of our technology in our own backyard, here in Ontario,” said Curtis VanWalleghem, Hydrostor CEO, in comments to POWER. “This facility serves as an important proof point for A-CAES on the global stage, enabling the build-out of Hydrostor’s full-scale project pipeline in Canada, the USA, Chile, Australia and other markets. This is the showcase of the A-CAES technology.”

The innovation behind Hydrostor’s Goderich facility makes it a worthy recipient of a POWER Top Plant award.

First Utility-Scale, Commercial Application

The Goderich plant represents a major milestone for Hydrostor, as it’s the company’s first revenue-generating commercial facility. The plant has 1.75 MW of peak power output; a 2.2-MW charge rating; and provides up to 15 MWh of storage capacity. Goderich is a first-of-its-kind utility-scale commercial application of A-CAES technology, conforming to all interconnection, uptime, performance, and dispatch standards as set out by the IESO, with which it has a 10-year contract to provide energy services.

“New technologies are changing the way we keep the lights on for Ontarians,” said Peter Gregg, president and CEO of the IESO. “NRStor and Hydrostor’s Compressed Air Energy Storage project is a great example of the innovation we’re seeing in this province, and will help us further understand how these unique resources can best integrate with Ontario’s market and system operations, and drive down costs for consumers.”

Hydrostor told POWER, “The facility demonstrates the ability of Hydrostor’s A-CAES technology to fully participate in and deliver a range of valuable grid services to electricity markets.” It noted, “[N]ow that it is fully commissioned it serves as an important demonstration that the operating principles of A-CAES as a commercially available, long-duration storage solution [are valid].”

The Goderich plant, among other things, is envisioned as a replacement for gas-fired peaking capacity. Hydrostor said the facility will lower electricity costs for ratepayers, and also have a positive environmental impact. The company said it expects more than 20,000 metric tons of greenhouse gas emissions will be avoided in the first decade of operation for the plant.

Hydrostor used the company’s Toronto facility as a research and development project to validate the concept behind the Goderich plant. The company said the Toronto plant “demonstrated the A-CAES approach to hydrostatic compensation of the air storage using underwater storage vessels, [while] the Goderich facility uses an underground cavern. This shift towards underground caverns greatly improves the technology’s siting ability, making it a much more valuable solution for utility customers. Not only can the land-based storage facility be sited further inland, it can also leverage existing transmission infrastructure and brownfield sites [such as abandoned mines] to cut costs and deliver projects more quickly.”

An Unconventional Approach

Hydrostor said the first conventional CAES facility was commissioned in Huntorf, Germany, in 1978, with a second facility built in McIntosh, Alabama, in 1991. Both remain in operation, using diabatic (gas-fired) CAES technology. Hydrostor said this traditional CAES has two drawbacks, starting with its reliance on natural gas to heat the air during the discharge cycle. “This negatively impacts round-trip efficiency, and the use of a fossil fuel results in associated carbon emissions and higher operating costs,” Hydrostor said. “Second, since conventional CAES facilities require very large underground caverns, the technology could only be sited in very select locations with uncommon geology [typically salt formations]. Given the fuel reliance and siting limitations of conventional CAES it would generally make more economic sense to simply build a natural gas fired generating facility where needed on the grid.”

The Hydrostor A-CAES system “was specifically designed to address both of these limitations,” the company told POWER. The company’s co-founder, Cameron Lewis, developed wind projects and saw there would be a need for a scalable long-duration energy storage technology. Lewis, who also worked in Alberta’s oil and gas industry, looked at the limitations of such a system and saw the need to develop a fuel-free A-CAES solution “that could be more readily sited where the grid needs it.”

To reach that solution, A-CAES uses only machinery and techniques already proven at scale in the power, mining, and oil and gas sectors “to develop a bankable and highly scalable solution to one of green energy’s toughest problems.” Lewis founded Hydrostor in 2010 along with VanWalleghem. In the decade since, the Hydrostor team has developed and demonstrated the A-CAES technology, optimized its design, and built up its project delivery capabilities. The company has its eye on building its first large-scale (200-MW or larger) facility that will work with global grid applications.

Hydrostor said, “A-CAES provides low-cost bulk long-duration storage like pumped hydro, but has the key ability to be flexibly sited where the grid needs it, allowing the targeting of high-value [and immediately available] grid applications like transmission deferral and fossil plant replacement.” The company said the technology “operates similarly to a conventional natural gas plant but is entirely non-emitting—it can be quickly ramped up or down while its rotating turbomachinery provides valuable inertia and synchronous generation that stabilizes the grid and contributes to power quality.”

Providing Value to the Grid

The company said the technology’s ability to provide synchronous storage capacity, and its flexible siting, is valuable to grid operators—a benefit that outweighs the impact of slightly lower round-trip efficiency. Hydrostor noted that as a long-duration technology this is less of a concern, and that as more renewable energy is added to the grid, the cost of the power is lowered, “which in turn makes the cost of inefficiency less of a burden financially.” Moreover, cost-effective long-duration storage technologies are increasingly needed to replace conventional generating capacity as grids worldwide continue to decarbonize.

Hydrostor said A-CAES is more cost-effective than batteries at scale, with a 50-plus-year asset life and “is ideally suited to providing the long-duration storage resource necessary for decarbonizing the grid. This remains true for many applications even with long-term forecasts of cost reductions in lithium-ion batteries.” ■

—Darrell Proctor is associate editor for POWER (@DarrellProctor1, @POWERmagazine).