O&M

-

O&M

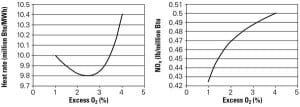

Improve Furnace Reducing Atmosphere Using Fuel/Air Ratio Control

Progress Energy has incorporated online combustion optimization/tuning to eliminate furnace reducing atmospheres at its Asheville Plant. The optimization project utilized individual burner airflow measurement and continuous burner coal flow measurement to adjust burner air/fuel ratios. The result: significantly improved boiler combustion.

-

O&M

Work Process Optimization: Meeting the Challenge of Change

The competitive push for more efficient power generation prompted the management of East Kentucky Power Cooperative’s Spurlock Station to provide training and to implement standardized work processes in order to achieve higher productivity. To that end, Spurlock’s management collaborated with salaried and hourly personnel to design and implement work process optimization. Two years later, their proactive, operations-driven culture is promoting continuous improvement at this facility.

-

O&M

Real-Time Monitoring System Measures Air In-Leakage

The amount of air leaking into the boiler envelope is difficult to estimate. Traditional methods of measuring oxygen at the furnace exit and economizer exit do not account for all types of air leakage. By using molar calculations and total airflow measurement, a good approximation of the total air in-leakage rates of a boiler can be quickly determined using station instruments.

-

O&M

New Coating System Extends Life of Cooling Tower

American Electric Power’s (AEP’s) Cardinal Power Plant Unit 3 cooling tower in Brilliant, Ohio, was coated and lined in the spring of 2008 by a team of coatings professionals that included the plant’s project and coatings engineering staff, Sherwin-Williams (coatings supplier), Cannon Sline Industrial (contractor), and OTB Technologies (third-party inspector). The team completed the project in just 11 weeks through damp springtime conditions in the Ohio River Valley.

-

O&M

New Process Transforms Waste into Product for Controlling Emissions

In April, Solvay Chemicals Inc. commissioned a new facility that uses an innovative process to recover and transform sodium carbonate waste streams into a market-grade sodium bicarbonate used in air emissions control.

-

O&M

Use Dry Fog to Control Coal Dust Hazards

Fogging systems have been successfully used in the material-handling industry for more than 30 years to control explosive dust at transfer points. Today, fogging systems are an EPA Best Demonstrated Technology for subbituminous coal preparation plants.

-

O&M

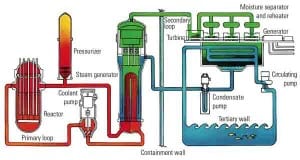

Variable-Frequency Drives Upgrade Reactor Circulating Pumps

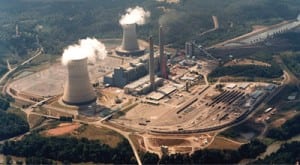

A recent trend in nuclear power plant upgrades has been the replacement of the motor-generator (MG) sets that drive the reactor circulating pumps with variable-frequency drives (VFD). Siemens’ first application of VFDs in this industry began in 2000 with an installation of six VFDs at the Browns Ferry Nuclear Plant. The use of the VFD continues to expand, and upgrades were recently completed at several U.S. plants, including the Hatch Nuclear Plant in Georgia.

-

O&M

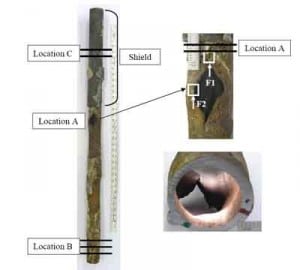

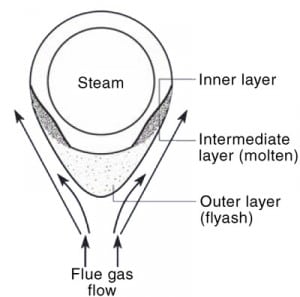

The Role of Fireside Corrosion on Boiler Tube Failures, Part II

One of the primary challenges of reliably burning coal is managing the corrosion experienced by the furnace heat transfer surfaces. Fireside corrosion remains a leading cause of failure in superheater and reheater tubes. In Part I, we examined three case studies of different failure modes experienced by tubes located throughout the furnace. In Part II, we conclude with two additional boiler tube failure case studies.

-

O&M

Improving SCR Performance on Simple-Cycle Combustion Turbines

Austin Energy replaced the selective catalytic reduction (SCR) catalyst twice over five years for its four peaker turbines. The duct modifications and injection grid redesign, combined with new catalyst, are producing high NOx reduction and low ammonia slip, and the catalyst is now expected to last at least five years.

-

O&M

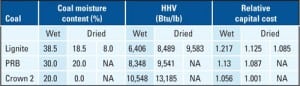

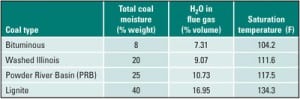

Power 101: Flue Gas Heat Recovery in Power Plants, Part II

Every power engineer must have a firm grasp of the rudiments of how fuel is processed to produce electricity in a power generation facility. With this article, we continue our three-part series on the essentials of recovering heat from flue gas to dry and process coal, with the goal of improving overall plant operating efficiency.

-

O&M

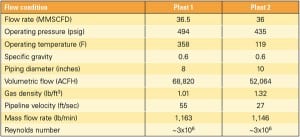

Real-Time Monitoring of Natural Gas Fuel Cleanliness

Gas turbines require clean gas to operate efficiently. Particulate contamination fouls fuel nozzles, causes increases in flue stack emissions, and occasionally causes unplanned plant outages. Now a new real-time natural gas cleanliness monitoring and web-based alarm system is providing valuable protection for natural gas–fired power plants. The adaptation of laser light–scattering technology for the purpose of contaminant measurement in high-pressure gaseous pipelines provides a method of monitoring liquid and solid contamination levels.

-

O&M

Competitive Maintenance Strategies, Part III

This third and final installment addresses three more areas where an investment in good maintenance practices pays operating availability dividends.

-

O&M

Natural Gas Piping: It’s Time for Better Risk Control

At least 10 workers have died from natural gas piping explosions in the past 12 months. The most recent disaster, which occurred during gas system purging at the Kleen Energy Systems plant, claimed five lives and injured 27 workers. It’s time the industry understood the unique design and safety requirements for working with and purging natural gas piping.

-

O&M

Forensic Engineering: A Valuable Tool in Incident Investigations

Much like the crime scene investigators on the CSI TV shows, power plant investigation teams are increasingly employing forensic engineering methods to gather evidence and determine the causes of malfunctions of equipment, materials, or products that result in personal injuries or property damage. Case studies show how different investigation teams used their forensic engineering expertise to examine a dust collector explosion, a coal terminal fire, and the failure of a forced draft fan.

-

O&M

A Burning Concern: Combustible Dust

If not properly controlled, coal and coal dust can cause fires, explosions, and implosions at power plants. Strategies for promoting safer management of these combustibles include actions such as training personnel exposed to the hazards of coal and coal dust about safe handling methods.

-

O&M

Laser Hole-Shaping Improves Combustion Turbine Efficiency

Laser shaping technology has evolved from a two-step process into a single process that drills and shapes holes through a TBC, bond coat, and airfoil base metal to create a finished product.

-

O&M

Competitive Maintenance Strategies, Part II

Nearly every combined-cycle operator recognizes that cycling reduces the life expectancy of hot-gas-path components in combustion turbines. Often overlooked, however, is that the same phenomenon affects the heat-recovery steam generator (HRSG).

-

O&M

A Primer on Optimizing Fleet Operations

The power industry needs a straightforward definition of "fleet optimization" and a game plan to achieve the promised economic gains of optimizing. This need has become more urgent because integrating nondispatchable renewable resources requires more complex optimization strategies. The bottom-up approach presented here applies well-understood optimization principles and techniques that will help power producers minimize their fleetwide cost of production, independent of the technologies used to generate electricity.

-

O&M

Enhanced Condenser Tube Designs Improve Plant Performance

Enhanced condenser tube designs can significantly improve the heat rate and performance of fossil and nuclear plants. Using the optimum number of tubes and replacement tube sheets will cost more than simply replacing plain tubes. However, the investment’s simple payback is measured in only weeks, which builds a strong case for using an enhanced tube design as part of your next condenser overhaul.

-

O&M

Deciphering Desuperheater Failures

The "combined" portion of a combined-cycle plant is the heat-recovery steam generator (HRSG) that generates high-pressure and high-temperature steam and the steam turbine generator that expands the steam to produce electricity. Integrating the HRSG and steam turbine with the combustion turbine is a key challenge for plant designers, as each system has differing operating profiles, operational constraints, and design requirements.

-

O&M

The Role of Fireside Corrosion on Boiler Tube Failures, Part I

One of the primary challenges of reliably burning coal is managing the corrosion experienced by the furnace heat transfer surfaces. Fireside corrosion remains a leading cause of failure in superheater and reheater tubes. Three case studies examine the different failure modes experienced by tubes located throughout the furnace.

-

O&M

Power 101: Flue Gas Heat Recovery in Power Plants, Part I

Every power engineer must have a firm grasp of the rudiments of how fuel is processed to produce electricity in a power generation facility. With this article, we begin a series of Power 101 tutorials that present these fundamentals in a clear and concise way. First up are the essentials of recovering heat from flue gas.

-

O&M

The Unique Challenge of Controlling Biomass-Fired Boilers

Biomass has many advantages as a fuel for boilers: It’s inexpensive, readily available in many regions, CO2 neutral, and its use warrants government subsidies. The fuel also presents unique concerns to the designers, owners, and operators of biomass plants, especially in the design of the control system.

-

O&M

Venezuela’s Power System on Brink of Collapse

Venezuela, a country that relies on hydropower for almost three-quarters of its electricity, has been battling a deepening electricity crisis since a drought in 2009 and a sudden 7% surge in demand brought the country’s power system to the brink of collapse.

-

O&M

Competitive Maintenance Strategies

Many consultants are prospering today by creating "new" maintenance strategies. What they’re really creating is new buzzwords.

-

O&M

Restraining Torsional Vibration

All rotating equipment power trains found in a power plant have some amount of vibration, usually caused by mechanical unbalance of the rotating system, shaft misalignment, or weakness in the bearing support.

-

O&M

Conveyor Upgrades Increase Plant Availability, Reduce Airborne Dust

The loading and discharge of conveyor belts is the area where many, if not most, of the problems in solids conveying occur. Fortunately, a new technology provides chutes to accomplish conveyor loading and discharge without blockages while minimizing the dust generated: engineered-flow transfer chutes.

-

O&M

A Game Plan for Improving Boiler Operations

Operating a boiler is not difficult, but operating a boiler safely and efficiently requires skill and proper training. Following boiler operation best practices will keep your equipment in like-new condition for years to come. This game plan includes a compendium of best practices, with web links to a number of additional key resources you should be famililar with.

-

O&M

Fuels Used for Power Generation Expected to Rebound in 2010

The Energy Information Administraion has predicted that, as the economy gathers steam this year, rising demand for gasoline, crude oil, coal, and natural gas is expected to push up energy prices, aided by a projected boost in crude oil production.

-

O&M

Can Your Boiler Feed Pump Handle a Deaerator Pressure Transient?

In a typical steam power plant, the boiler feedwater (BFW) pump takes suction from the deaerator (DA) and discharges high-pressure water to the boiler through the feedwater heaters. During normal operation, the DA is supplied with steam turbine extraction steam to mix with and heat the feedwater.