A Burning Concern: Combustible Dust

If not properly controlled, coal and coal dust can cause fires, explosions, and implosions at power plants. Strategies for promoting safer management of these combustibles include actions such as training personnel exposed to the hazards of coal and coal dust about safe handling methods.

"The serious losses in life and property resulting annually from fires cause me deep concern. I am sure that such unnecessary waste can be reduced. The substantial progress made in the science of fire prevention and fire protection in this country during the past forty years convinces me that the means are available for limiting this unnecessary destruction."

That statement was made 63 years ago as part of President Harry S. Truman’s address to attendees of the President’s Conference on Fire Prevention. Truman’s perspective on fire prevention is as valid today as it was then.

Thirty-seven years ago, a group of topic experts summarized their findings and recommendations about fire prevention in a report titled America Burning (Figure 1). Much of this report focused on the three Es of safety: engineering, enforcement, and education. However, the significance of this 1973 report was that it was the first time the federal government focused on and recommended a more coordinated approach to fire protection and fire prevention. America Burning and its follow-up, America Burning Revisited (1987), provided a roadmap for improving fire safety.

1. A burning issue. The National Commission on Fire Prevention and Control published America Burning in 1973. The report sought to bring attention to the serious issue of losses of life and property caused by U.S. fires. A pdf of the report is available at www.usfa.dhs.gov/downloads/pdf/publications/fa-264.pdf. Courtesy: The National Commission on Fire Prevention and Control

My father, who gave me my own copy of America Burning, spent a lifetime both starting fires and preventing them. During his 58 years in the fire service, he started fires in a controlled environment to learn about fire’s behavior and, more importantly, to train others how to effectively mitigate the losses once one started. At the same time, he used that knowledge to drive change. He hoped to change people’s behaviors so they would prevent and survive fires, and he sought to modify regulations so that they are clear and helpful. In that spirit, the goal of this article is to draw our industry’s attention to a fire danger that often remains unacknowledged: combustible coal dust.

Our Goal: "Zero Harm" from Combustible Coal Dust

The struggle to minimize fires continues today. In our industry we are primarily concerned with fires in power plants, and coal plants are particularly suceptible to fires because of the presence of combustible dust (Figure 2).

2. Dust collector detonation. This explosion was caused by combustible coal dust in a dust collector. Courtesy: American Electric Power

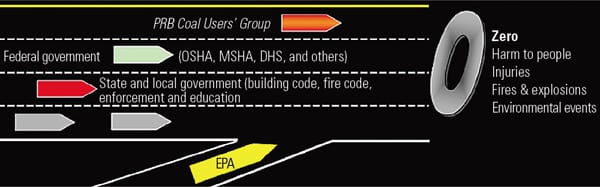

Many entities must work together to create a culture in which coal is safely and efficiently burned in a steam generator: federal, state, and local governments; standards-making organizations; and industry (Figure 3). Substantial progress has been made in the past 10 years by one particular organization — the PRB Coal Users’ Group (see sidebar). This organization succeeds by regularly bringing together users and potential users of Powder River Basin (PRB) coal plus other interested parties who share best practices, educational and networking opportunities, and a forum to support each other in the safe and efficient handling of PRB coals. This is evident in their collaborative efforts related to developing recognized best practices, such as those concerning mill inerting, coal silo/bunker fire protection, electrical practices, and risk assessment tools. The group is also responsible for high-quality programming at its annual meeting on combustible coal dust.

3. Destination “Zero Harm.” Federal, state, and local governments must have the same goal as standard-making organizations and industries to promote the safe and efficient handling of coal in power plants and other industrial facilities. Source: American Electric Power

It should be clear that coal is combustible. After all, we use it because its combustion can be used to produce steam. We also know that many fires, and even implosions and explosions, occur in our industry that damage people and property while causing financial and productivity losses. It is clear that the federal government recognizes the importance of addressing combustible dust, in part, through the U.S. Occupational Safety and Health Administration (OSHA), which first issued a National Emphasis Program (NEP) and now is writing a combustible dust standard. Most within the industry ask that whatever vehicle (standard) OSHA issues be clear, achievable, and avoid undue burden on the regulated community. Any forthcoming legal requirement must be realistic and practical so we can reach our goal of zero harm.

Understanding the Hazards of Combustible Coal Dust

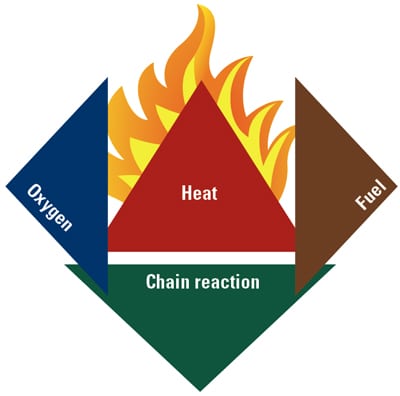

We can learn how to prevent fire by understanding what it takes to create a fire. Another one of those life lessons from Dad: What’s common in putting out a fire is common to what it takes to prevent one. Four elements must be present: fuel (coal), oxygen (air), an ignition source (heat), and a chemical reaction. What’s often misunderstood is the role that chemical reaction has in the fire process. Simply put, coals can sometimes spontaneously combust as a result of an exothermic reaction (such as PRB coals absorbing moisture). So removing at least one element from the others is a simplified approach to fire suppression and prevention (Figure 4).

4. All fired up. Four elements must be present to ignite a fire: fuel (coal), oxygen (air), an ignition source (heat), and a chemical reaction. Source: American Electric Power

Combustible dust is defined by the National Fire Protection Association 654 (proposed) as a combustible solid that presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations, regardless of particle size or shape. (Note the elimination of 420 micron size from previous definitions.) Three main types of events can be caused by combustible dust:

-

Flash fire: A fire that spreads rapidly through a diffused fuel such as dust, gas, or the vapors of an ignitable liquid without the production of damaging pressure. (Source: Definition from NFPA 654 – proposed.)

-

Explosion: The bursting or rupture of an enclosure or a container due to the development of internal pressure from a deflagration. (Source: NFPA Glossary of Terms — NFPA 69.)

-

Implosion: The rapid inward collapsing of the walls of a vacuum component or device as the result of failure of the walls to sustain the atmospheric pressure. (Source: NFPA Glossary of Terms — NFA 86.)

Much emphasis has been placed on explosions, and they should be of great concern to anyone who manages combustible dusts of any kind. But in our business of using coal to generate electricity, we also must concern ourselves with flash fires. The reality is that flash fires are likely to occur more often than explosions as a result of the methods used during housekeeping or maintenance.

Implosion is also a danger. It’s amazing how people will gather to watch an old building come tumbling down. Sometimes implosion is used to intentionally destroy buildings to control the debris better. In a coal-fired power plant, the opening of dust collectors, crushers, and mills are a few examples of "containers" that under the right conditions — such as when smoldering coal is contained within — can implode once a doorway or other opening is breached with oxygen/air. All too often a devastating result occurs and affects fire department personnel who are unfamiliar with the equipment, coal, and the inherent hazards of both.

The conclusions that the authors of America Burning came to are the same ones we reach when we discuss coal. That is, the frequency and severity of coal fires do not result from a lack of knowledge of the causes, means of prevention, or methods of suppression, but rather because we fail to adequately apply and fund known loss-reduction strategies.

Strategies for Improving Combustible Dust Management

Together, OSHA’s NEP on combustible dust and the PRB Coal Users’ Group’s work provide a solid foundation for improving combustible dust management. What follows are some necessary overarching guidelines.

Collect and Analyze Fire Protection Information. The continuous and complete collection of data and, more importantly, the analysis of information that identifies solutions that prevent harm when placed into action are so important yet so often incomplete. It has been said that one is more likely to hear about the "big boom" than the many "flashes" that occur. We must be attentive and take actions that address flashes and other events that may seem less significant but that in reality are possible indicators of future hazardous incidents.

Create a Political Action Infrastructure. There must be organized and coordinated initiatives at the federal, state, and industry levels that strive to identify overall problems, establish reasonable solutions, and make things happen. Unlike many other social and economic issues that have coordinated national representation, fire and safety often receive extensive attention only following a major event involving personal injuries and/or property damage.

Some argue that combustible dust is a safety and health issue, while others insist it is a fire issue, but it is both. Representatives of the relevant governmental agencies must recognize this simple fact, work in harmony, and collaborate with industry so that together these different groups can identify and implement a clear and effective course of action.

Change the Cultural Orientation. Some of the most critical factors to consider are the attitudes, behaviors, and values of companies, plants, and individuals related to fire, safety and health, and safe and efficient coal management (Figure 5). Success in preventing fires, explosions, and other hazardous incidents involving coal dust can only be achieved if unconcerned attitudes and careless habits are changed.

5. Accident waiting to happen. Good plant housekeeping practices are vital when handling PRB coal. Ensuring that coal dust does not accumulate should be a fundamental safety concern for every plant manager. Courtesy: American Electric Power

Improve Education. Clearly, coal-handling personnel require more knowledge about the effective management of coal and combustible dust. This means that continued efforts need to be made in educating and creating awareness of methods for safely handling coal and preventing fires. Those who are exposed to coal dust — including, but not limited to operators, maintenance personnel, contractors, engineers, managers, industrial fire brigades, and public fire department personnel — need to be educated on its hazards and risks as well as safe handling methods to prevent harm.

The Road Ahead

We have indeed made great strides toward protecting people from fire, but we have much farther to go. Here are a few questions to ponder that are designed to help your organization improve its fire prevention initiatives:

-

What do you do on a regular basis to prevent fires?

-

What do you expect your subordinates (or supervisors) to do routinely to prevent fires?

-

How are your and their prevention activities measured?

-

How do you reward (or how are you rewarded) for performance?

-

What information do you have that shows you have control over fire protection (or that fire protection is under control) in the organization?

-

Why do we continue to count the things we don’t intend to happen, such as the number of fires, as our main performance indicator?

-

How can we expect to manage results we don’t want to achieve?

America is still burning, and only we can change the frequency and severity of fires. Take a break from looking at a computer or sitting in on another meeting to walk around the first process at coal-fired power plants: the coal-handling area. Seek knowledge from proactive groups such as the PRB Coal Users’ Group, from industry technical experts, and from within your company. Then put into action methods to safely and effectively manage combustibles such as coal and coal dust. Work in preventive mode!

—Bob Taylor ([email protected]) is with American Electric Power’s environment, safety and health organization and currently serves on the board of directors of the PRB Coal Users’ Group. He is a principal member of the NFPA 1081 (Industrial Fire Brigades) Technical Committee and has extensive background in fire, safety, health, security, and management systems.