Using Predictive Analytics to Keep Up with Energy Demand

Silicon Valley Power implemented a system using machine-learning technology to monitor critical power plant components. The solution has proven to reduce downtime and save money. Furthermore, its wireless predictive maintenance program has provided an outstanding return on investment.

In September 2017, a heat wave was at its peak in California. Pacific Gas and Electric reported power outages in the San Francisco Bay Area. The state’s energy grid was grappling with an unprecedented challenge. If demand exceeded supply, emergency measures, including rolling blackouts, would have been needed. The state had not experienced that in years.

Silicon Valley Power (SVP)—the municipal electric utility owned and operated by the City of Santa Clara, California—provides power to more than 53,000 residential and business customers. SVP’s mission is to be a progressive, service-oriented utility, offering reliable, competitively priced services. SVP has managed to maintain the lowest electric rates among California utilities, and it has won numerous awards, including for high customer satisfaction and for its use of renewable energy.

SVP’s main in-town generating facility, the Donald Von Raesfeld Power Plant, is a 148-MW natural gas-fired facility. Operating since 2005, it is a two-on-one combined cycle plant, employing two combustion turbines and one steam turbine. Santa Clara is the data-center capital of the U.S., and the power generated by SVP is a critical part of the high-tech economy infrastructure. The City of Santa Clara has aggressive green energy goals, and SVP currently provides 40% of its power from renewable, carbon-free resources, a significantly higher percentage than the California mandate. As renewables become a larger part of the mix, gas power plants have to ramp their output up and down, increasing the stress on equipment.

Periodic Monitoring Inadequate

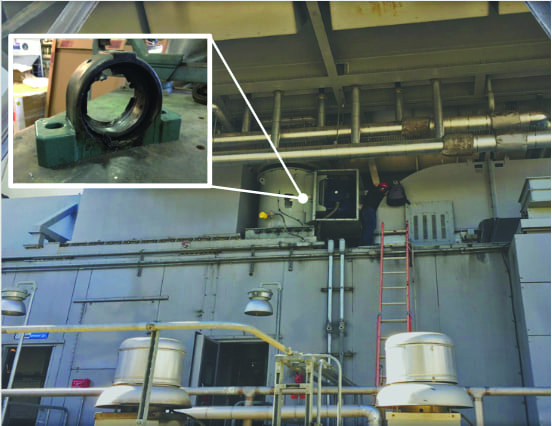

A generator cooling fan is a critical component for power generation facilities. If the fan fails (Figure 1), the gas turbine must be shut down or it runs the risk of collateral and structural damage, breakdown, or even a catastrophic failure. The generator fan is difficult to monitor with periodic vibration monitoring, because it often cycles and may not be in service during a scheduled walkaround.

A few years ago, SVP experienced a catastrophic failure of a generator cooling fan. In that case, the catastrophic failure occurred when the fan separated from the shaft and ricocheted inside the enclosure, shattered, became pulverized into a powder, and migrated into the generator, forcing a shutdown of the generator for four weeks and incurring costly repairs. SVP had been using a monthly walk-around program for vibration monitoring. The method, though widely used in the industry, has three main challenges:

- ■ By collecting data only once a month, some problems that emerge between monthly rounds can be missed.

- ■ Manual data collection introduces errors by not collecting vibration data during similar operating conditions because loads and conditions vary; this results in inconsistent data leading to potentially inaccurate inferences about machine health.

- ■ The analyst reports can be lost or too technical, requiring specialized knowledge in vibration analysis to interpret them.

Critical gas and steam turbines are usually well-instrumented and suitably monitored, but for every turbine there are also numerous mission-critical, balance-of-plant (BOP) pieces of equipment, such as pumps, motors, gearboxes, and fans. In some cases, these are maintained on a preventative, time-based schedule in accordance with manufacturer recommendations.

Until recently, the majority of SVP’s auxiliary machines were being monitored manually each month; workers monitored conditions (such as vibration, motor current, thermography, and other parameters), checked alignment, greased bearings, and more, at regularly prescribed intervals. Even with these preventative measures, the company was still finding severe mechanical defects during planned maintenance shutdowns. The repairs and replacements would prolong SVP’s outages by days or even weeks, which made a major impact on the company’s ability to achieve full-capacity energy production.

The Value of Continuous Monitoring

SVP recognized that it needed a system that would provide continuous monitoring, easy access to data, real-time alerts, and automated analysis. It conducted a trial with Petasense, an industrial internet of things (IIoT) startup, on several critical pumps.

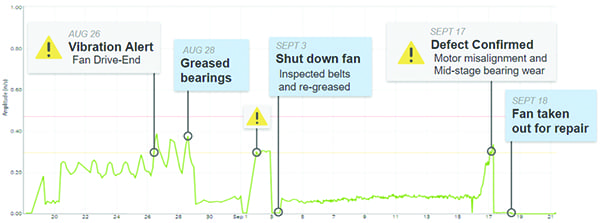

Petasense provides permanently installed wireless sensors (called Motes), and software that uses a combination of vibration analysis techniques and advanced machine learning to accurately predict equipment problems (Figure 2). Petasense’s software assigns each machine a machine-health score. This health score is based on a sophisticated machine-learning algorithm that analyzes the extent of deviation of a vibration measurement from a multidimensional baseline and provides real-time management alerts when the score falls below an acceptable number.

The pilot quickly yielded success detecting potential failures, and when SVP decided to expand the equipment monitoring to other critical assets, the generator fans were prime candidates given the recent catastrophic failure. Just as the heat wave hit in September 2017, SVP received a real-time alert on a generator cooling fan. The fan was running at alarming limits (abnormally high vibration levels). The alert showed a machine-health status of 4, far below the acceptable level of 7 (within the software, machines are assigned a health score of 1 to 10 based on deviation from the baseline). A lot of shaft speed harmonics of high amplitude—indicative of rotating looseness—were observed on the free end of the fan.

In this particular case (besides unplanned downtime and huge repair costs), it would have meant less power supply to the energy grid at a time when the demand was swiftly climbing. Given the criticality of the situation, Petasense had an in-person meeting with the reliability team at SVP. After close analysis and examination of data, SVP decided to take immediate action and shut down the unit pre-emptively, on Petasense’s recommendation, to carry out repairs.

The plant was back up and running within a matter of hours. Bearings were greased and the faulty bearings were replaced. The generator fan was restored and vibration on the motor and fan were returned to acceptable limits, allowing SVP to continue to produce energy to meet peak industrial demand. The temporary shutdown and repair cost $100,000, but had the defective fan gone unnoticed, the unplanned downtime and repair costs could have easily exceeded $1,000,000.

According to Paul Manchester, SVP’s operations and maintenance manager of Generation, “With a wireless predictive maintenance system, we get notified automatically as soon as a machine defect starts to develop, which saves us a tremendous amount of time and money. We’re no longer collecting data manually, we’re no longer performing preventive maintenance on machines that we know are healthy, and we’re no longer worried about a machine suddenly failing and costing us downtime. We saw the benefits of the solution literally within days.”

Implementing a Larger Solution

With roots in Silicon Valley, SVP is always looking for innovative ways to improve its efficiency and deliver safe, reliable power to its customers. By using Petasense’s predictive maintenance technology, SVP is at the forefront of embracing the latest innovations in sensing, wireless technology, and big data analytics. SVP is now in the process of implementing Petasense across its entire plant, including other multiparametric IIoT sensors that will cover different types of assets and bring in more data from existing assets.

Multiparametric monitoring is expected to bring a more-holistic picture of asset health. Just as a person has multiple lab tests performed by a doctor, incorporating multiple different sensor inputs provides a better diagnosis. SVP is planning to incorporate data such as temperature, pressure, current, ultrasound, and vibration to not only have better diagnoses, but to also have a better understanding of operating performance and its impact on maintenance.

Instead of looking only at vibration data in isolation, the machine-learning algorithms can analyze vibration under the same conditions, including variable parameters like speed and load. The system can also be configured to trigger alarms only when load is within a certain range. This is especially important in asset optimization for equipment like pumps that often operate sub-optimally, even without underlying faults.

SVP has been using the OSIsoft PI system for its data historian since 2004, expanding to a full enterprise-wide deployment in 2013. It uses OSI PI as its primary source of asset information, being used to optimize generation and distribution assets, and tracking process parameters to ensure uptime and operational efficiency. As such, it was important for vibration data from Petasense Motes to integrate with the plant’s PI system.

Part of SVP’s expansion of wireless IIoT included a pilot project to integrate Petasense with the PI data historian. This is expected to enable managers to correlate asset and process data, and create predictive models that leverage vibration along with other process parameters. The combination of process and vibration data will allow SVP to maximize asset reliability and process performance by equipping its engineers with a multiparametric view of the data, better insights, and more powerful analytics to make informed operations and maintenance decisions.

SVP recognized the advantages of IIoT, in particular, the low cost, simplicity, and scalability of the program. Wireless predictive maintenance is a cost-effective way of implementing IIoT, as it can expand monitoring to equipment that is not instrumented without additional wiring costs, dedicated servers, or other costs related to programming the distributed control system and system administration software.

Chris Karwick, SVP’s division manager of Generation, said, “By launching a wireless predictive maintenance program, we have already realized an outstanding return on investment.”

The ability to work with existing systems and the possibility of expanding to more than vibration sensors in order to make better asset decisions were both important in the overall IIoT program. After the successful trial, SVP outfitted all its critical BOP equipment with Petasense Motes, including cooling tower fans, boiler feed pumps, generator fans, and condensate pumps. As a result, maintenance costs have been reduced by 15% to 30% and unplanned downtime has decreased by 2% to 5%. The company is now reviewing opportunities to expand the program beyond rotating machines to include equipment such as steam traps, transformers, valves, and electrical panels.

Often, it can be difficult to separate the excitement of future IIoT technology from today’s reality. Some companies start with complete digital transformations, while others find success by focusing on a specific need and building from it. Both can be successful, depending on the execution and the company culture, but the key is to be able to show real, tangible results that others in the organization can see.

This example shows how SVP had a specific need to incorporate more-frequent data collection in order to reduce failures. It quickly witnessed excellent results from the implementation of new technology, and expanded its IIoT framework to a larger perspective. The company’s next steps of integration, including adding more multiparametric monitoring and expanding to more assets, will help the City of Santa Clara continue to deliver on its promise to provide safe, reliable, low-cost power. ■

—Arun Santhebennur is the co-founder of Petasense. Petasense offers an end-to-end, easy-to-deploy, predictive maintenance system.