Artificial intelligence (AI) is rapidly transforming the power sector, offering unprecedented opportunities for efficiency and innovation. But as AI applications proliferate, new challenges are emerging. How will industry navigate the…

Artificial intelligence (AI) is rapidly transforming the power sector, offering unprecedented opportunities for efficiency and innovation. But as AI applications proliferate, new challenges are emerging. How will industry navigate the…

Operators of utility-scale commercial solar farms know the importance of predictive maintenance for their installations. Being proactive when it comes to developing operations and maintenance (O&M) programs can help operators…

Data analysis is helping operators in the solar power sector develop more efficient systems that optimize operations and deliver cost savings. Utilities and other developers of solar power installations know…

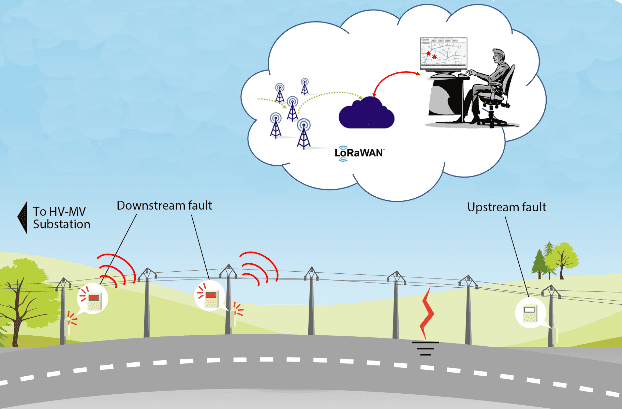

Obtaining real-time operating data on power plant and substation equipment has never been easier. The sensors, transmitters, and systems needed to monitor important parameters are readily available and highly cost-effective.…

Are the benefits of digital integrated power transformers worth it? Smart transformers with exciting new technologies like Internet of Things (IoT) and artificial intelligence (AI) are among the next generation…

The traditional approach to maintenance has two motors that keep it running. The first motor is proactive service: regularly maintaining equipment, following a schedule to ensure each element is running…

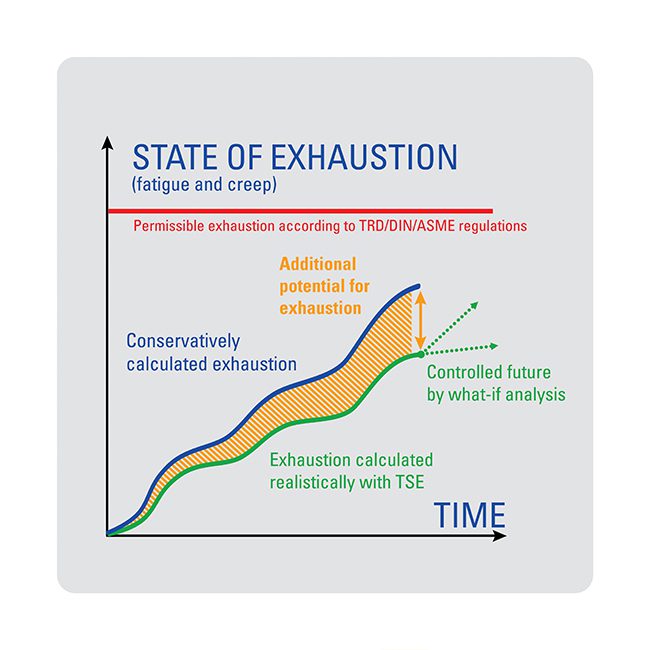

An innovative software program, coupled with an experienced team of engineers, allows plant operators to evaluate creep and fatigue stress in components exposed to more frequent cycling, thereby identifying potential…

Industrial Internet of Things (IIoT) technology is changing how power plants operate. One generating station incorporated new wireless vibration sensors with data from its existing historian system to better identify…

Artificial intelligence (AI) and machine learning (ML) are becoming synonymous with the operation of power generation facilities. The increased digitization of power plants, from equipment to software, involves both thermal…

Digitization in the power generation sector continues to expand. Its goal in simple terms—providing easy access to data for power plant operators and engineers, enabling the use of advanced analytics…