Intelligent Control of FBC Boilers

Optimizing combustion control is critical to reducing emissions and increasing plant operating efficiency, particularly for fluidized bed combustion (FBC) boiler plants burning biomass fuel that has unpredictable moisture content. The secret: measuring actual energy flow.

Plant designers must differentiate solid fuel combustion applications such as fluidized bed combustion (FBC), grate firing, and pulverized coal because each requires unique control strategies. It is also important to develop control strategies for each application that are simple to implement and support in the field. These strategies should also be easy to understand by plant staff, and equipment maintenance should not require a high level of instrumentation and control expertise.

The control system strategy employed must also be compatible with the overall boiler control system strategy, not be platform restricted, and not be solely dependent upon mass fuel flow to function properly. It is our experience that the best performing controls systems are based on the measurement of actual energy flow, which is described in more detail later in this article.

The boiler control strategy must also be capable of dynamic operation so that changing load at maximum rate will not cause boiler upsets or instability. This well-known strategy uses the boiler output plus the derivative of boiler drum pressure to predict the energy required to change to the new load setpoint (see “Drum Pressure the Key to Managing Boiler Stored Energy” in the June 2007 issue of POWER). Furthermore, a nonregenerative feedforward signal should be used to determine the overall firing rate demand. The control system should be able to run in automatic generation control (AGC) or continuously at design load. AGC is important to all utilities that have remotely dispatched plants, and it is now expected to be an integral part of boiler and turbine control systems. As one utility engineer recently told me, “We won’t build it if we can’t dispatch it.”

The sidebar describes two 100-MW net biomass plants now under construction for which Metso supplied the boiler island and integrated control system with features described in this article. For more information on FBC strategies when burning biomass, see the October 2010 article, “FBC Control Strategies for Burning Biomass” in the POWER archives at www.powermag.com.

Conventional Boiler-Turbine Coordination

In many industrial installations there are multiple boilers supplying steam to a process and/or steam turbines driving electric generators. The turbines can be connected to a steam network and operate in backpressure mode or condensing mode. There are as many different combinations as there are plants. However, what is typically missing is the coordination of the turbines and steam hosts with the boilers. The need to balance operation of the numerous boiler-turbine configurations must also be addressed in any robust industrial control system strategy.

The normal approach for a plant with multiple steam turbines fed from a common steam header that’s fed by one or more boilers is to control the header pressure. In too many cases, the turbines and pressure-reducing stations are operated in pressure mode (sometimes called turbine follow mode). In this case, each boiler’s fuel flow rate is controlled to produce the necessary steam flow and the steam header pressure is maintained by the governor valves of each turbine.

The control strategy for this industrial system is straightforward. The boiler demand should be based upon steam header pressure and a feedforward signal, which is divided among the various boilers according to their relative size and efficiency. The control system should allow for manual bias by the operation of individual boiler demands.

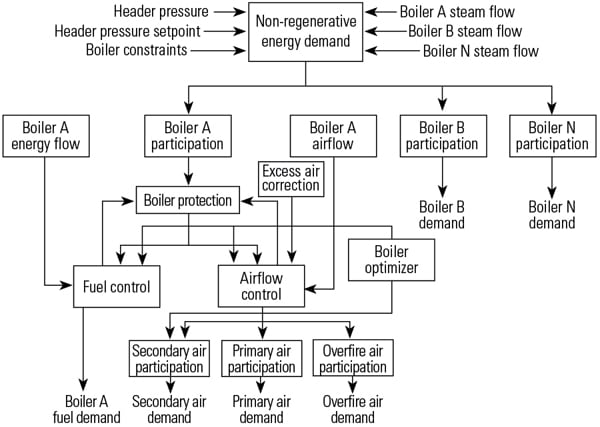

The nonregenerative feedforward should be the primary control for the boiler. The pressure control should provide minimal integral action. Integral control should be used sparingly in the boiler demand. The feedforward should not be steam flow, as this is a regenerative feedforward because regenerative feedforwards in the control system of a solid fuel–fired boiler tend to drive the demand in the wrong direction when an upset occurs or if fuel quality changes. In other words, a boiler upset condition will cause the pressure control to oppose the corrective change in the boiler controls and cause further upsets and destabilization (Figure 1).

|

| 1. Robust industrial boiler control strategy. An advanced boiler control in an industrial configuration with the energy flow computation and boiler control system optimizer has the ability to accurately control the output because it knows the input energy flow. Note that each boiler on the header has a “participation algorithm,” which allows for apportioning the demand according to its individual size, efficiency, and response. Also, the operator has the ability to manually bias the firing rate of each boiler, if required. Source: Metso Automation |

FBC Boilers Are Unique

FBC boilers are used for a wide variety of mostly industrial applications, with several boilers working together on sophisticated steam networks that have rapidly changing demand. The boilers acting in parallel can also be uncontrolled, where the boiler steam production is completely dependent upon the rate of waste fuel supply, which may not be measurable.

FBC boilers also are likely to use relatively hard-to-burn fuels such as combinations of biofuels and waste coal, all of which will have a wide range of possible fuel constituents and moisture content. Biofuels are not necessarily homogeneous; often they are a mixture of different fuels such as bark, forest cuttings, agriwaste, and waste building materials. A typical FBC will fire a wide range of solid fuels to minimize overall plant fuel cost.

FBC boilers burning these fuels require a much different approach to boiler control design. For example, the fluidized bed of sand and ash within the furnace has a very large inertia, limiting the dynamics of the boiler. On the other hand, the large fluidized bed of sand and ash enables the FBC boiler to burn up to 60% high-moisture-content fuels. While the fuel properties may change quickly, the fuel also burns relatively fast, even though there is still a wide range in the fuels’ combustibility (the time to evaporate the water, pyrolyze the solid fuel, and complete combustion).

How quickly the combination of fuels is fed into the FBC is the responsibility of the fuel feed system controls, a critical function of the overall combustion control system. The fuel feed system must be capable of handling multifuel combustion because the heating value and bulk density of the individual fuels will vary greatly. Even so, the total energy flow must be maintained at a consistent rate to make sure header steam pressure is maintained at setpoint and energy flow out of the boiler is at required demand. Changes in energy flow to the boiler can cause fluctuations in combustion and steam production. If not precisely controlled, these fluctuations will reduce power generation and can risk plant availability.

FBC boilers do not produce high levels of emissions, such as SOx and NOx. However, those that fire coal require limestone as an additive to capture SOx. Limestone is expensive to use and is an expense to overall operations that can reach several million dollars each year, depending upon the size of the boiler. Because FBC boilers operate at lower temperatures, NOx production from an FBC boiler is minimal, but if the bed temperature rises above the NOx threshold, more ammonia is required as a mediating additive. These emissions are all bed temperature–sensitive and require extreme optimization to maintain low levels of emissions. Thus, fuel control—without any compensation for changes in moisture, composition, or heating value—is problematic.

How to Manage Energy

The FBC is capable of multifuel operation because the control strategy includes a computation called the Fuel Power Compensator (FPC). The FPC was developed for the world’s largest biomass-fired boiler, Alholmens Kraft Power Station, a 240-MW unit operating in Finland since 2002. This unit can reliably burn any combination of biomass and coal. Its biomass is a combination of peat, bark, and wood residue. Coal is the backup fuel.

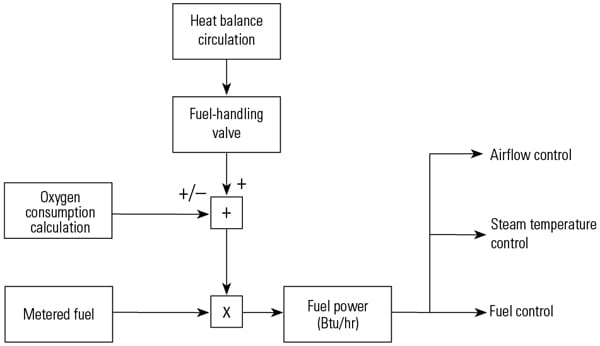

The continuous measurement of oxygen consumption by the actual fuel consumed and the boiler energy balance calculations are the essence of the FPC. Oxygen consumption is estimated by the excess air ratio and combustion airflow. Both computations are required because the energy balance calculation is based upon averages and is relatively slow, but it is very accurate. The oxygen consumption calculation is relatively fast, often taking milliseconds, but it has errors because of the transport delay from combustion to oxygen measurement. Combining the two measurements provides an accurate view of what is happening in the furnace in real time (Figure 2).

|

| 2. Best of both worlds. Some combustion control designs use airflow (as a proxy for oxygen flow) and an air/fuel ratio to estimate the energy entering a boiler—a process that is fast but error-prone. Others measure the actual fuel consumed—a slow but accurate approach. In combination, a much more accurate estimate of the energy entering the FBC boiler is possible. The Fuel Power Compensator computes the energy input by measuring oxygen consumption and mass balance. The result is used by the fuel control, airflow control, and steam temperature control loops. Source: Metso Automation |

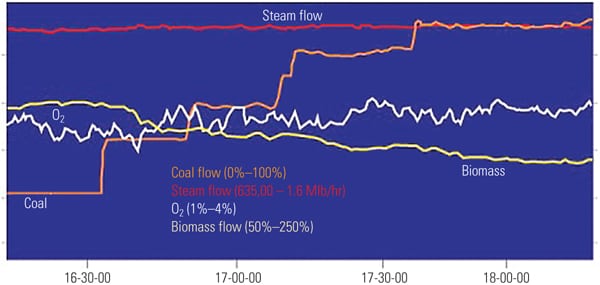

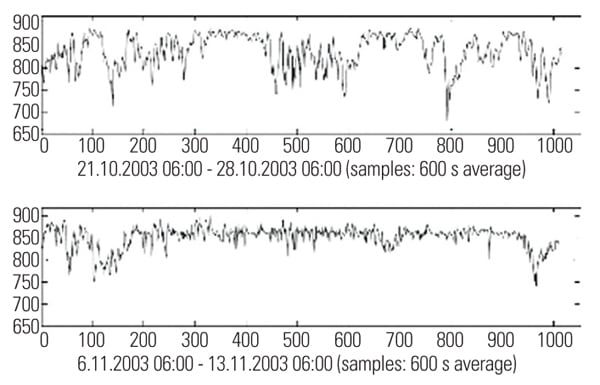

The FPC has been used on many multifuel boilers with excellent results. For example, Figure 3 is a strip chart of several performance parameters of the Alholmens biomass plant, which uses the FPC algorithms.

|

| 3. Well-controlled Nordic biomass plant. The 240-MW Alholmens Kraft Power Station is the largest biomass power plant in the world and burns a combination of coal and waste biomass fuels. The plant uses the Fuel Power Compensator (FPC) to optimize FBC boiler performance. In this recording, the operator is manually adding coal in 10% to 15% steps while the fuel control is responding to the FPC and driving the biomass flow downward to maintain constant energy output. Note how the steam flow remains unchanged during the fuel split change. Source: Metso Automation |

Optimize FBC Boiler Operation

There are many different types of optimization programs available that are based upon model predictive control, fuzzy logic, and neural networks. We suggest that you select a technology that meets the control strategy objectives of the plant, as discussed above. The selection should mesh with the existing control system and provide biases to setpoints in the control system. It should also be capable of running on a PC or on the control system controller. The best selection will use standard and/or existing process instrumentation in the plant, such as oxygen analyzers, flow and pressure transmitters, and online emission analyzers.

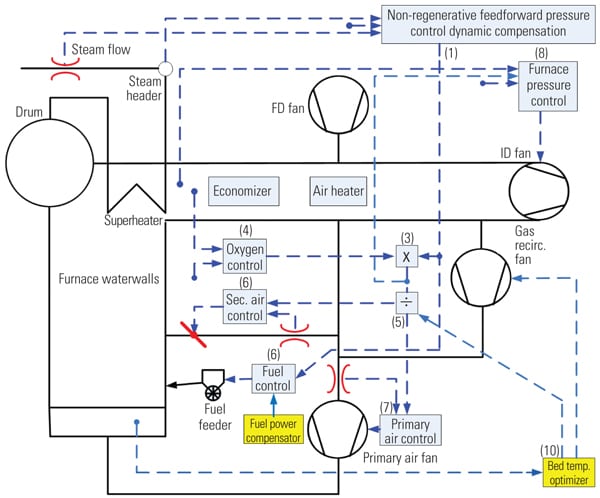

Figure 5 provides an overview of the basic controls used on a typical FBC boiler. The load is controlled by the steam demand in the form of a non-regenerative feedforward based upon steam flow, steam header pressure, and steam header pressure setpoint. These are incorporated in the boiler demand calculation that includes dynamic compensation, a requirement for AGC. While the boiler integrates the difference between the energy input and energy output of the boiler, the pressure error is primarily only a proportional process. The long FBC boiler time constant does not permit pressure control to operate as an integral control. The change in boiler demand is due primarily to the change in the feedforward. Other changes to boiler demand result from fuel quality changes.

|

| 5. Basic FBC boiler controls. This is a typical control strategy for an FBC boiler with a gas recirculation fan. If a steam turbine is connected to the header, a more complex demand computation involving the steam turbine first-stage pressure and steam flows is employed. The biggest difference between this control system and that used in a conventional solid fuel–burning plant is the bed temperature and fuel feed control loops. In this design, the fuel demand signal goes to the fuel feeder control (11) and the airflow control (3), where excess air is used to trim airflow demand to the secondary air control (6) and the primary control (7). The ratio of secondary to primary air is set by the operator or the optimizer control (5). The induced draft fan controls furnace pressure according to a feedforward from the airflow demand (8). Bed temperature control is maintained by recirculating flue gas into the bed. The flue gas tends to slow combustion and reduce the bed temperature. Source: Metso Automation |

|

| 6. Fuzzy logic the clear winner. The objective of advanced bed temperature control is stable bed temperature. In this FBC boiler test, the average bed temperature recorded during a one-week reference period (upper line) is compared with the performance of the same FBC during another one-week test period, but running with advanced bed temperature control algorithms (lower line). Source: Metso Automation |

The most unique control loop associated with a FBC boiler is the bed temperature. The bed is composed of many tons of hot sand and ash that is fluidized by primary air. The fluidization process is very important to the control of emissions and to minimizing limestone consumption in a coal-fired FBC. Furthermore, bed temperature is a function of fuel quality and changing boiler load because it is a function of the thermal balance of the bed. This is perfect for the application of a fuzzy logic controller, which is outside the scope of this article. Nevertheless, it can be said that these advanced control functions work extremely well in a biomass plant where the fuel constituents and moisture content are unpredictable (Figure 6).

—Roger Leimbach ([email protected]) is director of sales and marketing for Metso Automation USA Inc.