O&M

-

O&M

How to Measure Flyash Levels

Measuring the level of flyash in your silos is not an easy task, in part because the flyash collected at one plant can be remarkably different from that collected at another plant, even if both fire the same coal. Such variability means that selecting the right instrument for your application is important.

-

O&M

Focus on O&M (July 2008)

Protection against arc flash more important than ever; Laramie River Station uses new coating technology; Protecting power plant pipes: Basics you must know

-

O&M

Digital radiographic systems detect boiler tube cracks

Boiler water wall leaks have been a major cause of steam plant forced outages. But conventional nondestructive evaluation techniques have a poor track record of detecting corrosion fatigue cracking on the inside surface of the cold side of waterwall tubing. EPRI is performing field trials of a prototype direct-digital radiographic system that promises to be a game changer.

-

O&M

Boiler optimization increases fuel flexibility

Burning spot market fuels can reduce plant fuel costs, but it can also introduce unexpected operational problems throughout the boiler island. Orlando Utilities Commission’s Stanton Energy Center optimized its Unit 2 combustion system and improved O&M practices as part of a project to increase the unit’s fuel flexibility without degrading reliability or heat rate. OUC’s attitude: If you can measure it, you can manage it.

-

-

-

O&M

Focus on O&M (April 2008)

Tag-teamed seawater cleanup; New cooling towers to improve river’s health; Back to school

-

O&M

The aging workforce: Panic is not a strategy

Leaders in the utilities sector talk a lot these days about talent. On one hand, they express concern about facing a shortage of knowledgeable staff as 76 million baby boomers exit the workforce. On the other, they worry about where they’ll find enough qualified people to remain competitive in light of the fierce battle for engineering talent that globalization has created. The antidote to these worries lies in reconfiguring HR practices.

-

O&M

Focus on O&M (March 2008)

New CIP standards leave questions unanswered/Solving common analyzer problems/Qualifying rebuild shops

-

O&M

Maintaining water sample panels improves plant availability

Even comedian Rodney Dangerfield got more respect than many plant water sample panels do. But power plants ignore sample panels at their peril. Those sample panels, and readings of the on-line analyzers they support, identify when multi-million-dollar systems have a problem that demands immediate attention.

-

O&M

Desuperheating valves take the heat

Hot reheat steam bypass actuators are some of the most critical, yet least understood components in a typical combined-cycle plant. If you’re using pneumatic actuators to stroke your main steam or hot reheat bypass valves in a cascading bypass system, you’re behind the times. Here’s a way to get better control of the bypass process, shorten unit start-up and train blending times, and decrease your plant’s heat rate—all at the same time.

-

O&M

Extend EOH tracking to the entire plant

Predicting combined-cycle system longevity and determining optimal maintenance intervals at the same time is difficult: It requires balancing repair costs against the risk of trying to squeeze that last bit of life out of some component before it fails. One solution to the problem is to extend coverage of an equivalent operating hours (EOH) preventive management program for turbines to the entire plant.

-

O&M

Focus on O&M (February 2008)

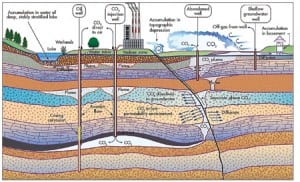

Survey captures industry’s carbon concerns; Sequestering coal plant emissions; Comparing mercury measurement methods

-

O&M

TVA’s Shawnee Fossil Plant Unit 6 sets new record for continuous operation

Shawnee’s new 1,093-day long-run record is a testament to the plant’s highly qualified and trained staff, excellent operations and maintenance processes, and the quality leadership required to keep all the moving parts pointed in the right direction. If running a power plant is a team sport, then the staff of Shawnee are in a league of their own.

-

O&M

Alliant Energy sweeps EUCG Best Performer awards

The Fossil Productivity Committee of the EUCG conducts an annual analysis of its member plants’ operating results and selects the Best Performer in the categories of small and large coal plants. For 2007, Alliant Energy’s Lansing and Edgewater Generating Stations took the top spots—the first time in recent history that a single utility claimed both awards.

-

O&M

Who’s doing coal plant maintenance?

POWER has reported on several EUCG benchmarking studies over the past several years. This month we examine the maintenance staffing of 45 coal plants reported by 13 EUCG member utilities. If you benchmark your plants or fleet, as you should, some of the study’s results challenge what is considered conventional wisdom.

-

O&M

The case for cathodic protection

All fossil fuels carry some risk with their reward of an energy density that’s sufficient for producing electricity economically. For coal and natural gas, that threat is a fire or explosion. However, the risk of an explosion isn’t limited to gas-fired plants. Gas poses a threat to any plant that uses the fuel, even in small quantities for heating. Here’s an overview of what you should be doing to keep gas pipelines from corroding and exploding.

-

O&M

Focus on O&M (January 2008)

Single-window control of CHP plant’s energy converters / Safety stuffers entertain as they inform / Doubling up for a heavy load

-

O&M

Eliminating oil whip–induced vibration after a steam turbine retrofit

Nobody expected driveline vibration to occur after a flawless retrofit of a 200-MW steam turbine. But when it did, Mitsubishi Power Systems and Exelon vibration specialists identified the symptoms and rapidly narrowed the list of possible causes. Confounding factors made the root cause difficult to identify, but the experts pinpointed the problem, made necessary hardware modifications, and placed the turbine back in service in a week.

-

O&M

Protecting plant equipment from voltage sags

Immunity from voltage sags is vital for reliable operation of our ever-more-sophisticated electronic controls and equipment. Every electrical product should be able to ride through typical voltage sags, but in many cases the first sag test occurs after equipment is installed and in operation. Select the appropriate sag immunity specification and equipment compliance testing, and you’ll be glad you did.

-

O&M

The Coal Patrol: Court Rejects Industry Suit Targeting Miner Safety Rules

A federal appeals court has rejected a National Mining Association (NMA) suit seeking to throw out new regulations issued by the Mine Safety and Health Administration (MSHA). The rules were to improve protection for miners in the wake of accidents at two West Virginia coal mines in January 2006 that killed 15. (See COAL POWER […]

-

O&M

Coal Plant O & M: Condition Monitoring Cuts Mirant Mid-Atlantic’s Costs

Condition monitoring (CM) has become an increasingly important aspect of power plant maintenance philosophy. Today many utilities are using a variety of predictive maintenance (PM) techniques like CM to lower their operation and maintenance expenses. Over the years, gencos have developed a diverse collection of CM programs of various breadth, depth, and formality. All are […]

-

O&M

Safety: Worker Health and Safety Now Top Priorities for Alabama Power

Employees of Alabama Power, a Southern Company subsidiary, routinely work near energized wires, intense heat, nuclear fuel, heavy equipment, moving vehicles, and pressurized equipment, as well as under other conditions that require exceptional safety attitudes and measures. Though it is vitally important to provide electricity to customers, neither company believes that doing so is worth […]

-

Commentary

Storming the Gates

Visiting power plants is one of the perks of being a COAL POWER editor. Some plants are located in metropolitan areas; others are closer to east nowhere, especially those mine-mouth plants. Each is unique and worth the travel time to visit and meet plant staff.

-

O&M

Focus on O&M (December 2007)

The web: Ideal for skills development / Upgrading a New Orleans pumping station / Turn plant failures into successes

-

O&M

Focus on O&M (November 2007)

The NERC auditors are coming / Winning encore for on-line pH monitoring / Using baloons as temporary barriers / How data logging can cut power bills

-

O&M

Plantwide data networks leverage digital technology to the max

To make the most of their digital devices and enable the sharing of data by different departments, new and old plants alike need a reliable digital data infrastructure.

-

O&M

Upgrade your BWR recirc pumps with adjustable-speed drives

The U.S. is home to more than 30 boiling water reactors of BWR-3 through -6 vintage. At one time or another, all have experienced obsolescence, reliability, or control problems with their reactor recirculation flow control systems and components. Temporary down-powers are often required for corrective maintenance. Exelon Nuclear plans to begin upgrading the recirculation pump motor drives at its BWRs in the spring of 2009. The upgrade project’s technical design and business case were developed in great detail before the project was approved. This article presents the results of all key internal analyses.

-

O&M

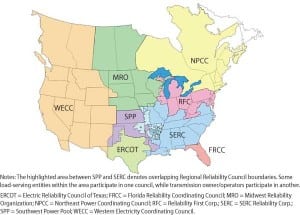

The Coal Patrol: Demand Growth — and Reliability — Are Still Supply-Limited

While noting marginal improvements since last year, America’s power reliability watchdog recently warned that the nation’s growing thirst for electricity will still far exceed planned increases in generation capacity over the next 10 years, and that reserve margins could dip below optimal levels within two or three years in California, the Rocky Mountain states, New […]

-

O&M

Tech Notes: Intelligent Sootblowing Needed to Keep Uprated Units Clean

The National Coal Council estimates that 40,000 MW of additional generating capacity is available to existing U.S. coal-fired plants simply by making efficiency improvements. Because decreases in production costs go straight to a plant’s bottom line, efficiency projects usually have short payback periods, especially if implemented in concert with mandatory environmental upgrades. One often-overlooked consequence […]