O&M

-

O&M

Can Your Boiler Feed Pump Handle a Deaerator Pressure Transient?

In a typical steam power plant, the boiler feedwater (BFW) pump takes suction from the deaerator (DA) and discharges high-pressure water to the boiler through the feedwater heaters. During normal operation, the DA is supplied with steam turbine extraction steam to mix with and heat the feedwater.

-

O&M

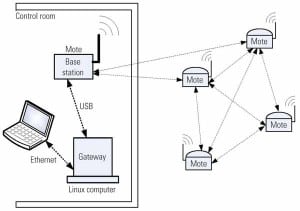

Low-Cost Wireless Sensors Can Improve Monitoring in Fossil-Fueled Power Plants

As equipment ages in fossil-fueled power plants, component wear leading to machinery failure increases as a result. Extending equipment life requires increased attention to maintenance, and one way to improve maintenance planning is to detect faults prior to failure so maintenance can be scheduled at the most cost-effective, opportune time. This type of strategy benefits from the use of additional sensors, and wireless ones can often be installed with the least time and cost.

-

O&M

How to Avoid Alarm Overload with Centralized Alarm Management

In 1999, the Engineering Equipment and Materials Users’ Association (EEMUA) released its general guide to the design, management, and procurement of alarm systems for industrial plants. The guidance document (EEMUA 191), however, is vague about applications to specific facilities, such as electric power plants. This article specifies EEMUA 191 standards and practices applicable to the electric power industry and spells out specific variations in alarming practices that are tailored for today’s power plants.

-

O&M

Replacing an HP/IP Rotor

Today’s power plant owners face many challenges, including the aging and degradation of equipment. Steam turbines at times may be condemned due to operating inefficiency or rising vibration levels. In such cases the options may be few because the turbine may require a full or partial rotor section replacement. The good news is that a rotor section replacement can be performed in a relatively short time, depending upon the original rotor configuration. Here’s one example.

-

O&M

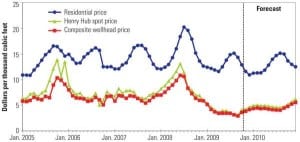

The U.S. Gas Rebound

"It’s déjà vu all over again," said Yogi Berra. The Hall of Fame catcher could easily have been predicting the coming resurgence of natural gas – fired generation. Yes, a few more coal plants will be completed this year, but don’t expect any new plant announcements. A couple of nuclear plants may actually break ground, but don’t hold your breath. Many more wind turbines will dot the landscape as renewable portfolio standards dictate resource planning, but their peak generation contribution will be small. The dash for gas in the U.S. has begun, again.

-

O&M

Sealing Transformer Oil and SF6 Leaks Quickly and Effectively

Transformers, which are prone to leaking, are an excellent example of where using the right materials and techniques can quickly reduce cleanup costs and potential environmental damage from a fluid leak. Transformer leaks are most commonly caused by degrading cork gaskets or holes in the radiator fins or the steel tank. Often these leaks are slow drips, but occasionally a catastrophic leak will occur, spilling hundreds of gallons of mineral oil into the environment and causing the transformer to short-circuit, causing further health and safety concerns. These dangers, coupled with transformers’ isolated locations, make inspection, repair, and maintenance a major challenge.

-

O&M

When to Use an Oil Skimmer

Oil skimmers are very effective in removing oil from wastewater before discharge but are also perhaps the most efficient and economical approach.

-

O&M

Four Methods of Fly Ash Sampling

There are four approaches to measuring fly ash content and, therefore, the quality of fuel combustion in a boiler. Before choosing one, you should understand their relative levels of complexity and accuracy.

-

O&M

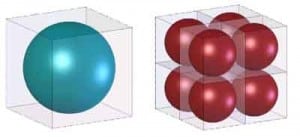

Ceramics Win the War on Erosion

Erosion can significantly reduce the operational life of boiler components. Abrasion-resistant ceramic parts can be a sound alternative to expensive metallic parts when replacing boiler components.

-

O&M

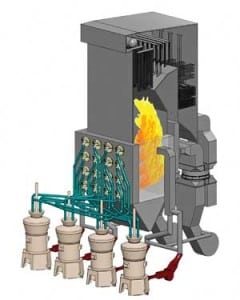

World’s Largest Circulating Fluidized Bed Boiler Begins Commercial Operation

When the Åagisza power plant began commercial operation in late June 2009, it marked the beginning of a new era in the evolution of circulating fluidized bed (CFB) technology. At the heart of this 460-MW plant is the world’s largest CFB boiler, which is also the world’s first once-through unit supercritical CFB boiler.

-

O&M

Rebuilding Feedwater Heaters While a Plant Is Online

Rebuilding aged feedwater heaters can make better economic sense than buying new ones, because rebuilding reduces capital cost and plant outage expenses. At one Texas generating station, rebuilding saved one-third the cost of a new feedwater heater while improving the plant’s heat rate.

-

O&M

Halar-Lined Chimney Remains Maintenance-Free

A fiberglass-reinforced plastic (FRP) Halar stack liner was installed at Vattenfall’s 300-MW Unit 2 at the Nordjylland Power Station in 1995. The 112-meter-high (367-ft) stack, protected from corrosion by the ECTFE liner, is still in excellent condition and has not required any repairs during more than 13 years of service. (ECTFE is short for ethylene chlorotrifluoroethlyene polymer, marketed under the brand name Halar ECTFE [Halar] by Solvay Solexis.)

-

O&M

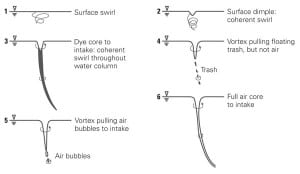

Scale Model Testing Confirms Adequate Refueling Water Storage Tank Vortex Allowance

Recent Nuclear Regulatory Commission (NRC) Component Design Bases Inspection activities have scrutinized empirical approaches used to determine vortex allowances for emergency core cooling system (ECCS) suction sources.

-

O&M

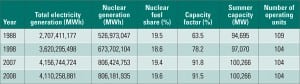

Benchmarking Nuclear Plant Operating Costs

In an exclusive agreement with the EUCG Nuclear Committee, POWER was provided access to some key, high-level performance and operational data from the group’s nuclear industry benchmarking database. All U.S., and many international, nuclear power plants are members of the committee and have contributed to its database for many years. This month we introduce you to the EUCG Nuclear Committee and share sample nuclear operating costs. Look for future reports on other key performance benchmarking metrics during 2010.

-

O&M

Modeling and Simulation Tools Reduce Plant Outage Duration

Replacing equipment inside a nuclear power plant requires careful planning that begins many months before the plant outage. Entergy has adopted advanced modeling and simulation tools that allow engineers to "walk through" the entire outage in a virtual model, thus avoiding unanticipated surprises.

-

O&M

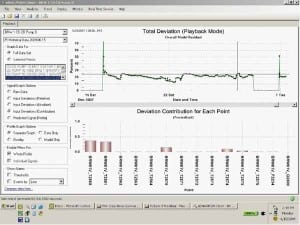

Catching Faults with Centralized Condition Monitoring

In 2007, Exelon Corp. began the Centralized Performance Monitoring (CPM) pilot program. The goal was to reduce downtime costs and lost revenue associated with the 25% of unplanned forced losses across its fleet of 17 nuclear power units without additionally taxing existing personnel or adding new personnel.

-

O&M

HDPE Replaces Carbon Steel in Safety-Related Pipe System

Corrosion of steel water pipes in the safety-related piping systems of aging U.S. nuclear power plants is fast becoming a safety concern and a significant operational cost, not to mention an indication of potential future liability for nuclear utilities currently constructing new plants or retrofitting existing sites.

-

O&M

Condenser Tube Life-Cycle Economics

The decision to retube a heat exchanger or condenser begins with understanding why tubes are failing. Only when the “why” is understood can the economic replacement tube material be selected. We explore the most common tube material failure mechanisms and then illustrate how to perform a proper life-cycle analysis for that new set of condenser tubes your plant so desperately needs. In sum, there are many reasons to consider getting the copper out of your condenser.

-

O&M

Texas Wind Boom Cutting into Fossil Generator Profits

Can wind turbines actually reduce the amount of fossil fuels consumed? A Wall Street Journal analysis concludes that ERCOT utilities will begin to feel the squeeze in their profits this year and to expect the amount of fossil fuels used to generate electricity to be reduced.

-

O&M

Zonal Combustion-Tuning Systems Improve Coal-Fired Boiler Performance

Coal-fired power plants that fire low-cost coals or that are equipped with combustion modifications for NOx controls are challenged with maintaining good combustion conditions while maximizing generation and minimizing emissions. In many cases, significant unit derates, availability losses, and an increase in unburned carbon levels can be attributed to poor combustion conditions that occur as a result of poorly controlled local air/fuel distribution within the boiler furnace. Fortunately, a new generation of combustion optimization technologies is available that uses burner air and fuel controls and spatially distributed combustion monitors to detect and correct local furnace air/fuel distribution imbalances.

-

O&M

Measuring Coal Pipe Flow

Once pulverized coal flows have been measured, they can be balanced and optimized. Until then, tuning is simply guesswork. The right way to balance furnace fuel flows is to establish solid baseline performance by proper measurement of fuel flow, fineness, and velocity. Only then can all the coal pipes be accurately balanced and followed by a tune-up of the boiler controls.

-

O&M

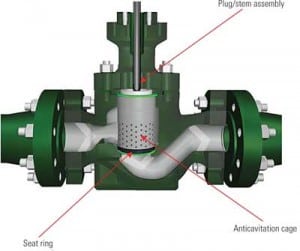

Proper Valve Selection Reduces Downtime, Increases Process Efficiency

Many customer quotation requests provide only the line size, pressure class rating, and valve type. A typical request might read: size 4, Class 900 globe valve. Though this may be enough information to produce a valve quote, it rarely is enough information to size the best valve from both a performance and cost perspective.

-

O&M

Ensure Your Valve Replacement Parts Meet OEM Specs

When high-temperature boiler feedwater passes through a control valve, the pressure drop can exceed several thousand pounds per square inch, placing extreme stress on the valve body and internal parts. If those parts are not engineered and manufactured to the highest industry standards, there is a very real possibility of the severe conditions damaging or destroying the valve.

-

O&M

Update: Benchmarking Boiler Tube Failures

Boiler tube failures continue to be the leading cause of downtime for steam power plants. Is your boiler tube failure reduction program showing improvement when compared to programs at peer plants? The EUCG’s recent update of its boiler tube failure study can help you answer that question. The full study is available only to members, but this POWER exclusive presents many of the key results, which could help you improve the operation of your plant.

-

O&M

Avoid These 10 Mistakes When Selecting Your New Water Treatment System

There are a number of reasons why your plant might be looking at new water pretreatment equipment in the near future. One common reason is the addition of new generating capacity. Regardless of the type of new generation, you can be sure that it will require additional high-purity water for processes ranging from direct steam generation to power augmentation, NOx control, and washing the blades of the combustion turbines.

-

O&M

Top Plants: Portlands Energy Centre, Ontario, Canada

Construction of the Portlands Energy Centre was a logistical dream: A mothballed power plant next door had an active switchyard, natural gas pipeline, and cooling water structure. The new facility put peak power into the Ontario Power Authority’s grid from its two combustion turbines only two years after collecting the necessary permits. The entire plant entered commercial service on April 23, 2009 — six weeks early.

-

O&M

Top Plants: Royal Pride Holland Commercial Greenhouse Cogeneration Plant, Middenmeer, North Holland Province, Netherlands

At Royal Pride Holland’s commercial tomato greenhouse, green thumbs and green energy go hand in hand. With a total energy utilization of 95% in this application, GE’s new Jenbacher J624 natural gas – fired engines offer the innovative greenhouse an economical supply of on-site electrical and thermal power, as well as CO2 fertilization, to support its operations.

-

O&M

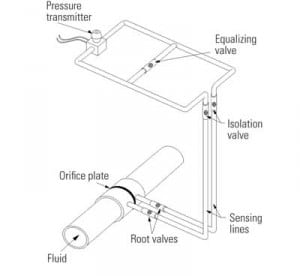

Pressure-Sensing Line Problems and Solutions

Improper pressure-sensing line design or installation is often found to be the cause of poor sensing system accuracy and response time. Here’s how to identify and solve those pesky pressure sensor problems in short order.

-

O&M

Accurate Online Silica Analyzers Ensure Boiler Performance, Add Boiler Life

One key area at the 800-MW Michoud power station where O&M excellence is evident is in maintaining plant water quality.

-

O&M

PRB Coal Users’ Group Educates Industry on the Dangers of Combustible Dust

The annual meeting of the Powder River Basin Coal Users’ Group was held in association with the ELECTRIC POWER conference in early May in Chicago. Get a taste of the festivities, technical meetings, and the announcement of the group’s 2009 Large and Small Plant of the Year winners in this conference report.