Coal

-

Coal

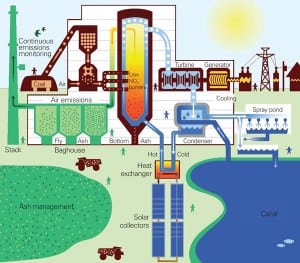

Xcel Energy Fires Up Solar/Coal Hybrid Demonstration

At the end of June, Xcel Energy fired up a demonstration project that integrates a 4-MW parabolic trough solar technology with an existing 44-MW coal-fired power plant.

-

O&M

Power 101: Flue Gas Heat Recovery in Power Plants, Part III

Every power engineer must have a firm grasp of the rudiments of how fuel is processed to produce electricity in a power generation facility. With this article, we conclude our three-part series on the essentials of recovering heat from flue gas to dry and process coal, with the goal of improving overall plant operating efficiency.

-

O&M

Improve Furnace Reducing Atmosphere Using Fuel/Air Ratio Control

Progress Energy has incorporated online combustion optimization/tuning to eliminate furnace reducing atmospheres at its Asheville Plant. The optimization project utilized individual burner airflow measurement and continuous burner coal flow measurement to adjust burner air/fuel ratios. The result: significantly improved boiler combustion.

-

Coal

Fourth Circuit Scuttles NC Air “Nuisance” Suit

Scuttling a high-profile “public nuisance” lawsuit, a federal appeals court has reversed a lower court ruling that required the Tennessee Valley Authority to accelerate plans to install pollution controls at four TVA coal-fired power plants to reduce the amount of pollution blowing into western North Carolina, saying the lower court decision could lead to other public nuisance suits that would wreak havoc on federal and state regulatory regimes for combating air pollution.

-

Coal

House Members Warn EPA on Coal Ash

Saying they have “grave concerns” about the agency’s two-option proposal to regulate coal combustion ash, 31 members of the House Energy and Commerce Committee have urged the Environmental Protection Agency to continue to regulate coal ash as a non-hazardous waste, saying an EPA proposal to designate it as a “special” hazardous waste eligible for reuse would lead to costly and unnecessary management and disposal requirements.

-

Coal

AEP Blasts EPA Transport Rule; PSEG Supports It

An Environmental Protection Agency proposal to tighten sulfur dioxide and nitrogen oxides limits in 31 states and the District of Columbia to address transported air pollution fails to give utilities and state air regulators sufficient time to develop rules and install controls, according to American Electric Power Co. Officials from the EPA and New Jersey-based Public Service Enterprise Group said utilities already had begun making investments to cut emissions and they believed the agency’s compliance schedule could be met.

-

O&M

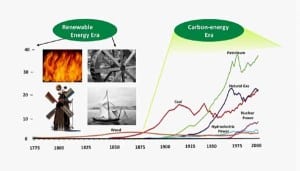

Wind Integration: Does It Reduce Pollution and Greenhouse Gas Emissions?

Many claim that wind generation is beneficial because it reduces pollution emissions and does not emit carbon dioxide. This isn’t necessarily the case. When wind is introduced into a generation system that uses carbon technologies to back up the wind, it actually reduces the energy efficiency of the carbon technologies.

-

Coal

Canada to Shutter Older Coal Plants

While the U.S. awaits congressional action on a cap-and-trade program that could possibly be limited to just the utility sector, Canada is moving, starting in 2011, to phase out older coal power plants and replace them with natural gas–fired plants. The announcement, made this June by Environment Minister Jim Prentice prior to the G8 and G20 summits, could have serious implications for coal-fired generators in the country.

-

Coal

Breathing Added Life into Failing Heat Exchangers

When heat exchanger tubes—sometimes numbering a thousand or more per unit—begin to crack or wear, the effects can lead to a cascade of subsequent failures in adjacent tubes. If too many tubes are plugged, heat exchanger effectiveness is compromised, and power generation may be curtailed. If conventional mechanical plugs are used, they can break loose, leak, and fail. At that point, the replacement of a very costly heat exchanger is imminent.

-

Coal

Protect Your Stack Linings from Corrosion

Stacks at power generating stations may be low maintenance, but they are not no maintenance. The cost of preventing corrosion may be as little as $10,000, but the cost of repair or replacement could be many times that or even put your plant out of commission until the stack problem is corrected.

-

Coal

Luminant’s Oak Grove Power Plant Earns POWER’s Highest Honor

Luminant used remnants of the ill-fated Twin Oaks and Forest Grove plants (which were mothballed more than 30 years ago) to build the new two-unit 1,600-MW Oak Grove Plant. Though outfitted with equipment from those old plants, Oak Grove also sports an array of modern air quality control equipment and is the nation’s first 100% lignite-fired plant to adopt selective catalytic reduction for NOx control and activated carbon sorbent injection technology to remove mercury. For melding two different steam generators into a single project, adopting a unique and efficient “push-pull” fuel delivery system, assembling a tightly integrated team that completed the project on time and within budget, and for completing what was started almost four decades ago, Oak Grove Power Plant is awarded POWER magazine’s 2010 Plant of the Year award.

-

Coal

Cleco’s Madison Unit 3 Uses CFB Technology to Burn Petcoke and Balance the Fleet’s Fuel Portfolio

With commercial operation of Madison Unit 3, Cleco Power now claims bragging rights for owning the largest 100% petroleum coke–fired circulating fluidized bed power plant in North America. For using readily available fuel in an environmentally attractive manner, adopting fuel-flexible combustion technology, balancing the utility’s generation portfolio, and adopting an innovative fuel-handling system design, Madison Unit 3 is the winner of POWER’s 2010 Marmaduke Award for excellence in operation and maintenance. The award is named for Marmaduke Surfaceblow, the fictional marine engineer and plant troubleshooter par excellence.

-

O&M

Real-Time Monitoring System Measures Air In-Leakage

The amount of air leaking into the boiler envelope is difficult to estimate. Traditional methods of measuring oxygen at the furnace exit and economizer exit do not account for all types of air leakage. By using molar calculations and total airflow measurement, a good approximation of the total air in-leakage rates of a boiler can be quickly determined using station instruments.

-

Coal

Advanced SCR Catalysts Tune Oxidized Mercury Removal

Catalysts used in selective catalytic reduction (SCR) systems in utility boilers provide high NOx removal efficiencies that routinely exceed 90%. A major co-benefit of applying SCR to coal-fired power plants is that the SCR catalyst also oxidizes the vapor phase mercury from an elemental form to a soluble ionic form, which can be readily captured in a downstream flue gas desulfurization process. Mitsubishi Heavy Industries and Cormetech have developed an advanced SCR catalyst technology with high mercury oxidation activity capable of achieving 95% oxidized mercury over a wide range of operating conditions.

-

O&M

Work Process Optimization: Meeting the Challenge of Change

The competitive push for more efficient power generation prompted the management of East Kentucky Power Cooperative’s Spurlock Station to provide training and to implement standardized work processes in order to achieve higher productivity. To that end, Spurlock’s management collaborated with salaried and hourly personnel to design and implement work process optimization. Two years later, their proactive, operations-driven culture is promoting continuous improvement at this facility.

-

Coal

Lean Construction Principles Eliminate Waste

Eliminate waste in coal, gas, or nuclear power plant construction through a holistic application of lean principles.

-

Coal

Drax Offers Model for Cofiring Biomass

When it is completed, later this summer, the UK’s Drax Power Station biomass facility will become the largest dedicated cofiring project of its kind in the world. As U.S. coal-fired generators come under increasing pressure to cut emissions and take advantage of incentives to promote power generation from renewables, Drax offers an example of what is possible.

-

O&M

Use Dry Fog to Control Coal Dust Hazards

Fogging systems have been successfully used in the material-handling industry for more than 30 years to control explosive dust at transfer points. Today, fogging systems are an EPA Best Demonstrated Technology for subbituminous coal preparation plants.

-

Coal

Industry Pivots on Natural Gas, Hails Cap and Trade

At the opening ELECTRIC POWER 2010 plenary session, both the keynote speaker’s address and discussion among the Power Industry Executive Roundtable participants pointed to the renewed appeal of natural gas and proposed cap-and-trade legislation as being potential game-changers for the U.S. power industry.

-

Coal

PRB Coal Users’ Group Celebrates a Decade of Achievement

The 2010 Powder River Basin Users’ Group (PRBCUG) commemorated its 10th anniversary with 354 registered members (210 of whom were from operating companies) for its three-and-a-half-day annual meeting in Baltimore this May. The meeting’s Grand Sponsor was Benetech and its Plant Professionals group.

-

Coal

EPA Proposes Two Options to Regulate Coal Ash

In an unusual two-option proposal that drew clashing views from green groups and power plant operators, the Environmental Protection Agency has proposed regulating coal combustion ash either as a nonhazardous waste subject to tougher management and disposal requirements or as a "special" hazardous waste that would have similar controls but still be eligible for recycling and reuse in products such as Portland cement.

-

Coal

EPA Issues Final Greenhouse Gas Tailoring Rule

Less than 24 hours after the unveiling of sweeping Senate legislation to reduce U.S. greenhouse gas emissions, the Environmental Protection Agency released a final Clean Air Act rule that defines emission thresholds for greenhouse gas permitting requirements for power plants and other large stationary sources.

-

Coal

American Power Act Dangles Carrots for Nukes, Coal, Gas

Facing a difficult uphill slog in a sharply polarized Senate, Sens. John Kerry and Joseph Lieberman have unveiled long-awaited draft climate change and energy legislation that includes billions of dollars in incentives for the nuclear, natural gas, and coal industries aimed at attracting enough bipartisan support to overcome an all-but-certain filibuster led by the Senate Republican leadership.

-

Coal

Comparing the Value of Single- and Double-Layer Insulation on Boiler Walls

Boiler insulation practices have moved from using a single layer to a double layer of the same total thickness in recent years. However, this dual-layer trend has a downside: higher installation costs and the opportunity for contractors to cut corners when installing insulation. It’s time to return to using single-layer insulation on power boilers.

-

O&M

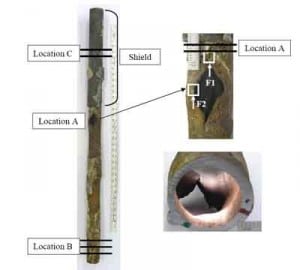

The Role of Fireside Corrosion on Boiler Tube Failures, Part II

One of the primary challenges of reliably burning coal is managing the corrosion experienced by the furnace heat transfer surfaces. Fireside corrosion remains a leading cause of failure in superheater and reheater tubes. In Part I, we examined three case studies of different failure modes experienced by tubes located throughout the furnace. In Part II, we conclude with two additional boiler tube failure case studies.

-

Coal

CORRECTED: New York Coal Plant to Get 20-MW Energy Storage System

New York regulators in April approved construction of a 20-MW energy storage system at the site of an operating coal-fired power station near Union, Broome County. When operational, the $22.3 million project, owned by AES ES Westover LLC—an AES Corp. subsidiary—will use the technology to participate in New York’s growing day-ahead market for ancillary services and regulation.

-

O&M

Power 101: Flue Gas Heat Recovery in Power Plants, Part II

Every power engineer must have a firm grasp of the rudiments of how fuel is processed to produce electricity in a power generation facility. With this article, we continue our three-part series on the essentials of recovering heat from flue gas to dry and process coal, with the goal of improving overall plant operating efficiency.

-

O&M

A Burning Concern: Combustible Dust

If not properly controlled, coal and coal dust can cause fires, explosions, and implosions at power plants. Strategies for promoting safer management of these combustibles include actions such as training personnel exposed to the hazards of coal and coal dust about safe handling methods.

-

Coal

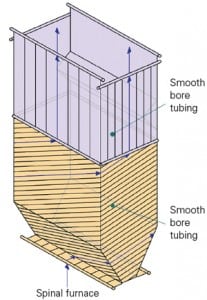

First Posiflow Benson Boiler Completes Seven Years of Service

Seven years have passed since the world’s first low mass flux vertical tube once-through furnace was put into operation by Doosan Babcock at the Yaomeng Thermal Power Plant Unit 1 in China. That boiler replaced a boiler of another design that had become unreliable. The operating experience with the Posiflow design has been so positive that the owner has since ordered and commissioned a replacement for Unit 2’s boiler. Here’s what makes this furnace design unique.

-

Coal

Adding Desalination to Solar Hybrid and Fossil Plants

Shrinking water supplies will unquestionably constrain the development of future power plants. A hybrid system consisting of concentrated solar thermal power and desalination to produce water for a plant, integrated with a combined cycle or conventional steam plant, may be the simple solution.