Xcel Energy Fires Up Solar/Coal Hybrid Demonstration

At the end of June, Xcel Energy fired up a demonstration project that integrates a 4-MW parabolic trough solar technology with an existing 44-MW coal-fired power plant. Designed to increase the plant’s efficiency, decrease its use of coal, and test the viability of solar power thermal technology, the project at the company’s Cameo Generating Station near Grand Junction, Colo., is being billed as the first of its kind in the U.S. (See “Fossil Fuels + Solar Energy = The Future of Electricity Generation” in POWER’ s April 2009 issue for an in-depth look at hybrid solar/coal systems.)

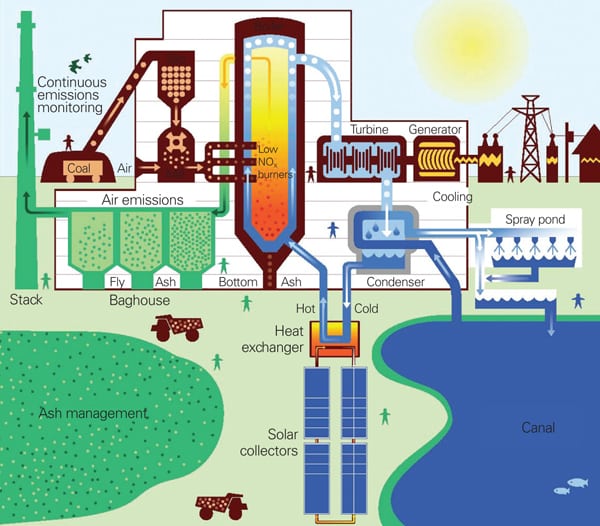

Designed by Spain’s Abengoa Solar, the concentrating solar power system consists of eight rows of 500-foot-long parabolic troughs covering 6.4 acres. Essentially, these solar collectors—specially curved “ultra pure glass mirrors”—concentrate incoming solar radiation at the focus of the parabola, where a line of receiver tubes is located (Figure 2).

|

| 2. The best of superterrestial and subterrestial power. Xcel Energy’s Colorado Integrated Solar Project near Grand Junction, Colo., uses parabolic trough technology at its coal-fired Cameo Generating Station to increase the plant’s efficiency and decrease the use of coal. Mineral oil used in the solar collectors is heated to about 575F and then used to preheat boiler feedwater from 360F to 407F, thereby reducing the amount of coal consumed to produce the same amount of power in the steam turbine. Courtesy: Xcel Energy |

The tubes are filled with a heat transfer fluid—Xcel uses food-grade mineral oil. That fluid circulates through the tubes and is heated to about 575F. A pump then circulates the heat transfer fluid through the heat exchanger. At the heat exchanger, heat from the transfer fluid is transferred to preheat the boiler feedwater, increasing its temperature from 360F to 407F. In the boiler, where pulverized coal is being burned, steam is produced, which then turns a turbine and generates power.

Xcel anticipates that the project will increase the power plant’s efficiency by up to 5%—by slashing the use of coal at the power plant nearly 2% or 3%—and will reduce carbon dioxide emissions by 2,000 tons per year. Testing should be completed by the end of this year, when the Cameo plant will be shut down. According to the Minnesota-based company, the $4.5 million project was built between September 2009 and February 2010.