Taean IGCC: Continued Operation, Continued Achievement

|

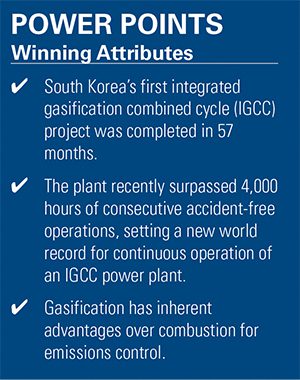

Korea Western Power’s Taean Integrated Gasification Combined Cycle (IGCC) Power Plant this year marked 4,000 hours of consecutive accident-free operations, setting a new world record for IGCC power plants.

South Korea last year set out to achieve carbon neutrality by 2050, vowing to end dependence on coal and replace it with renewables. Under the 9th Basic Plan for Electricity, the country plans to close 20 coal plants by 2034—in addition to 10 scheduled for closure in its 8th plan—with the aim of reducing coal’s share in its national power mix to 29.9% in 2030, compared to 40.29% in 2019. A significant facet of this plan are ambitions to switch 24 state-owned coal-fired units, a total 12.7 GW, to run on natural gas by 2034. While a specific roadmap has not yet emerged, the nation’s power plants will likely rely on domestically developed technology.

Leading that charge is Doosan Heavy Industries & Construction (DHIC), a regional energy technology conglomerate that has sought to establish itself at the core of South Korea’s strategy to become only the fifth country to own an independent gas turbine model. DHIC is also working, as part of a consortium of other South Korean firms, to build and demonstrate the country’s first large-scale hydrogen gas turbine. DHIC, notably, has spearheaded technology development for several first-of-their-kind coal technologies in use around the country, including at the nation’s first integrated gasification combined cycle (IGCC) demonstration project at Taean.

Demonstrating and Proving IGCC Technology

As the company recalls, South Korea began developing IGCC technology in 2006 as part of a renewable energy development project coordinated by the Ministry of Knowledge Economy. DHIC collaborated in this effort along with the Korea Institute of Energy Technology Evaluation and Planning, and Korea Western Power Co. (KOWEPO). By 2011, the company had snagged a $453 million contract with KOWEPO to build a 300-MW IGCC demonstration project at the utility’s existing 4-GW Taean power station in South Chungcheong Province.

At the time, interest in IGCC was growing, owing to its purported environmental benefits for coal power, which was slated to see a 400-GW expansion by 2030. South Korea, which already produced the bulk of its power from imported coal, envisioned 15 coal gasification plants producing 10 GW by 2020. Successful demonstration of the technology would open up new markets for coal, including for exports.

“An IGCC power plant is a process whereby a synthetic gas, consisting primarily of hydrogen and carbon monoxide, is extracted from coal and is used as the fuel to generate electricity,” the company explained in a 2011 press release. Along with capturing emitted carbon dioxide, the technology “minimizes the emission of other pollutants, including sulfur oxide and solid particulates,” it said. “If a coal gasification technology that minimizes the shortcomings of conventional coal-fired power plants, including the emission of pollutants, is commercialized, there is a high probability that coal could replace crude oil and natural gas in the foreseeable future.”

Groundbreaking on the pioneering project took place in November 2011, and following a remarkable 57-month construction timeframe—comprising 610,000 man-days and 49,000 pieces of construction equipment—the Taean IGCC project was declared operational on Aug. 16, 2016.

|

|

1. The Taean integrated gasification combined cycle (IGCC) project uses a Shell Coal Gasification Process (SCGP). This image shows the gasification unit under construction in 2014. Courtesy: Korea Western Power Co. (KOWEPO) |

At the heart of the Taean IGCC unit’s process is a gasification facility developed by Shell (Figure 1). GE supplied a 7F syngas combustion turbine, a D11 steam turbine, a heat recovery steam generator, and the unit’s Mark VIe integrated control system (ICS). It also signed a 10-year maintenance services contract for the facility. At the Taean IGCC plant, the 7F syngas turbine notably operates on syngas produced from the gasification of low-Btu coal. DHIC acted as both the gasification and air separation unit engineering, procurement, and construction contractor.

Industry observers have reported that the project has functioned mostly as designed. In November 2018, the unit refined its coal gasification gas extraction, and in November 2019, the unit reportedly succeeded in refining a 99.99% high-purity hydrogen. KOWEPO reportedly uses this refined hydrogen to demonstrate a 100-kW fuel cell system that uses polymer electrolyte technology. A project is reportedly underway to expand that system to 10 MW by 2025.

For KOWEPO and Doosan, the world’s dramatic turn away from coal power may have dampened their ambitions. However, they hold renewed optimism for IGCC technology given the current surge in interest in hydrogen’s role as a decarbonization driver. DHIC, for example, has reportedly proposed a system based on the Taean IGCC project that performs coal gasification, separates the hydrogen and carbon dioxide, and then uses the hydrogen for fuel cell power generation, while capturing the carbon dioxide.

A Continuous Operation Record

Meanwhile, as a testament to the technology’s soundness, KOWEPO ran the plant continuously for more than 4,000 hours between August 2020 and early February 2021. These hours were reportedly accident-free and set a new world record for continuous IGCC operation without failure. The previous records reported by the International Energy Agency’s Clean Coal Centre were 3,917 hours set by the Nakoso IGCC facility in Japan in 2013, and 3,993 hours set by the Tianjin IGCC facility in China in 2018.

|

Taean’s long-term continuous operation is especially remarkable because, owing to cost pressures and uncertainty around carbon emissions policy, several iconic IGCC plants have closed over the past decade. These include the 300-MW Puertollano unit in Spain and a 250-MW unit in Buggenum in the Netherlands. Tampa Electric has told POWER its 1996-completed 250-MW Unit 1 at the Polk Power Station in Florida is not currently operating, but “it has not been retired,” a spokesperson said. “It remains part of our long-term plans.” Plans to close the 1995-completed 265-MW Wabash IGCC in Indiana, meanwhile, appear to have been reversed to convert the plant’s gasifier to hydrogen firing with carbon capture and storage, and converting its gas turbine to fire with hydrogen as well.

Among existing still-operating large-scale IGCC projects are Duke Energy’s 2013-built 618-MW Edwardsport IGCC Station in Indiana, China’s 2009-built 250-MW GreenGen demonstration project in Tianjin, and the 1996-converted 400-MW Vresová project in the Czech Republic. In 2013, notably, Mitsubishi Power wrapped up a successful demonstration of the air-blown technology at the 250-MW IGCC unit at Joban Joint Power Co.’s Nakoso Power Plant Unit 10 in Iwaki, Fukushima. This April, a Mitsubishi consortium put online the 543-MW Nakoso IGCC facility in Fukushima. That facility’s gasifier uses Mitsubishi Power air-blown technology developed at Nakoso 10, essentially relying on a reaction between coal and air to generate the combustible syngas. Another unit using the same technology is slated to come online later this year at Tokyo Electric Power Co.’s Hirono Power Station in Futaba-gun, Japan.

—Sonal Patel is a POWER senior associate editor.