Harnessing Cooling Tower Plumes to Provide Purified Water

A novel technology that is surprisingly simple in principle promises to significantly reduce water consumption in evaporative cooling tower systems by capturing water from cooling tower plumes.

Cooling towers at power plants are essentially heat rejection systems that use significant quantities of water to dissipate heat from recirculating water. In wet cooling towers, the process involves evaporating a portion of the circulating water, producing heat transfer through both sensible heat of air and latent heat of evaporation.

A longstanding concern in the power industry involves the amount of water loss from cooling towers. Water is mainly lost through evaporation, which involves vapor dissipation into the ambient air during the heat rejection process. But it also occurs during blowdown, when the water has to be removed from the tower and replaced to prevent fouling and scale formation. Some water is also lost due to drift, which occurs when tiny droplets are entrained with the exiting air or vapor flow, though drift losses are typically minimal, comprising less than 1% of consumption.

Water losses can be substantial. The U.S. Environmental Protection Agency (EPA) suggests that regardless of cooling tower operating efficiency, about 1.8 gallons of water are evaporated for every ton-hour of cooling. “Traditional wet-cooled power plants lose 60% to 90% of their incoming water via cooling tower evaporation or drift,” noted Dan Sampson, a principal technical consultant at HDR.

In addition to being costly, these losses have other side effects. Because water evaporation requires continuous makeup from a water source, current and future water scarcity concerns may directly affect power plant reliability and viability. In 2017, two doctoral students from the Massachusetts Institute of Technology (MIT), Maher Damak and Karim Khalil, and MIT Professor of Mechanical Engineering Kripa Varanasi set out to address this pressing issue with a concerted focus on power plant plumes.

The Quest for Plume Abatement

When vapor leaves a cooling tower, it may, under certain ambient conditions (usually when ambient air is cold or humid), condense and form a plume of fog, the researchers observed. Plumes have long posed another concern for the power industry, the researchers noted. They can be a nuisance and even dangerous.

“Regulatory requirements relating to safety (drifting plumes can reduce visibility on roads and airports) and aesthetics, force some cooling towers to be equipped with plume abatement systems, which generally heat the exiting vapor and decrease its moisture content, either by heat exchangers or by blowing hot dry air and mixing it with the exiting vapor, thereby preventing the formation of fog droplets at the outlet of the tower,” they said.

While these abatement systems can remove the appearance of a plume, a power plant using them may still consume the same amount of water and suffer lowered overall net energy efficiency, owing to added heat requirements redirected to the cooling tower outlets. And while some devices have been designed to collect exiting vapor from cooling towers for reuse in the cycle, most methods rely on liquid or solid sorption, requiring significant energy or costly equipment.

|

|

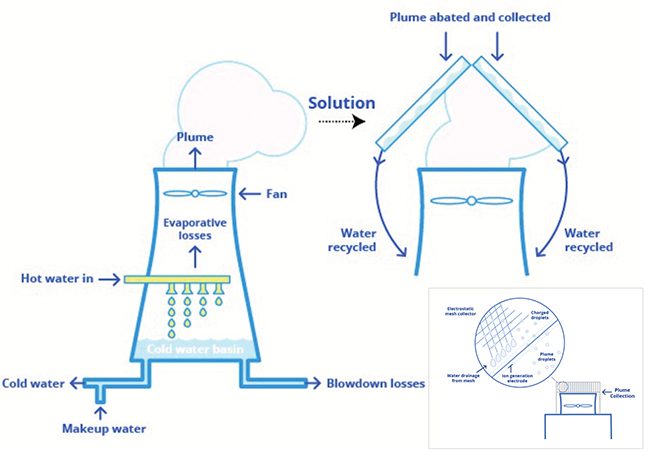

1. Schematic demonstrating location and use of Infinite Cooling’s retrofittable solution. Courtesy: Infinite Cooling / National Energy Technology Laboratory (NETL) |

Under a project fostered by the MIT Varanasi Research Group, the researchers developed the Water Panel (Figure 1). When air rich in fog is zapped with a beam of ions, the water droplets in the fog become electrically charged. These droplets can then be drawn toward a mesh of wires (like a window screen), captured, and drained into a collection pan. The power plant can then reuse that “harvested” water or send it to a city’s water supply system.

The system is essentially a distillation process that could allow a 600-MW power plant to capture as much as 150 million gallons of water a year—which represents about 20% to 30% of water lost from cooling towers, Infinite Cooling says. Research and development findings suggest water captured by the system typically measures below 50 microsiemens per centimeter—a measure of electrical conductivity that gauges water contamination. That compares to the 3,000 microsiemens per centimeter that water used in power plant cooling systems typically measure.

“The water recovery system could also serve as a simple desalination service. Installing the conversion system would cost about a third of that to build a new desalination plant—and its operating costs would be about 2% compared to a desalination plant. It would also have virtually no footprint,” the company said.

The Race to Scale Up

The concept became a core focus for Infinite Cooling, a startup company Damak, Khalil, and Varanasi founded in 2017. Damak serves as the nascent company’s CEO, Khalil as its chief technology officer, and Varanasi as chairperson. In 2017, the researchers joined 20 other teams in the MIT delta v cohort, a student venture accelerator that provides mentorship and incubation for student entrepreneurs to launch their businesses. Development of the concept has since dramatically ramped up, buoyant on interest from industry and academia.

Infinite Cooling went on to become the grand prize winner at the MIT $100K Entrepreneurship Challenge in 2018. It used that prize money to boost funding from the MIT Office of Sustainability to set up test installations in various configurations on one of the cooling towers of MIT’s natural gas–powered Central Utility Plant.

|

|

2. Shown here is a test installation of Infinite Cooling’s water recovery system at the Massachusetts Institute of Technology’s Nuclear Reactor Laboratory research facility. The right side of the tower has the new system installed, eliminating its plume of vapor, while the untreated left side continues to produce a steady vapor stream. Courtesy: Infinite Cooling |

When tests at the cogen plant showed that the system could eliminate the plume and produce high-purity water, Infinite Cooling was invited to conduct further tests at MIT’s Nuclear Reactor Laboratory research facility. The research reactor, which operates 24/7 and produces higher-temperature vapor emissions, offered a real-world test in an actual operating reactor licensed by the Nuclear Regulatory Commission (Figure 2).

As pivotally, it allowed Infinite Cooling to test the technology at scale and validate the water quality and performance of the system. “After the system was installed above one of the plant’s four cooling towers, testing showed that the water being collected was more than 100 times cleaner than the feedwater coming into the cooling system,” MIT said. “It also proved that the installation—which, unlike the earlier version, had its mesh screens mounted vertically, parallel to the vapor stream—had no effect at all on the operation of the plant.”

|

An Industry Demonstration on the Horizon

More recognition and competitive awards swiftly followed for Infinite Cooling. Accolades include the MassChallenge Awards, the Department of Energy (DOE) national Cleantech competition, and the Rice Business Plan Competition. As recently as April 2022, it took the gold award in the 2022 Edison Best New Product competition. But Infinite Cooling has also gained several notable federal grants to help it boost its development, including a $100,000 Phase I Small Business Innovation Research (SBIR) grant from the EPA in 2019. That award was recently increased to nearly $1 million as part of an SBIR Phase II grant.

Bolstered separately with a $1.5 million award under the DOE’s Water Management Crosscutting Peer Review, Infinite Cooling is currently exploring plume formation and collection on mechanical (induced) draft cooling towers. Tests are ongoing partly in a high-fidelity controlled environment and partly on a full-scale industrial cooling tower. That project, which is supported by the National Energy Technology Laboratory (NETL), is slated to wrap up in September 2022. It entails using a computational fluid dynamics (CFD) model to understand power plant plume characteristics and to inform test electrodes and collectors, which will make up modular panels that NETL will install on its cooling tower. Portions of the design will then be prototyped and tested on the lab cooling tower to evaluate collection efficiency. “The result will be a ready-to-deploy design for a high-throughput water collector for cooling tower plumes on an industrial cooling tower,” NETL said.

Once the design is complete, manufacturing of the modular collection panels and structure will begin. Then, under another recently awarded $1.1 million DOE-funded project that will wrap up in July 2024, the project team will build a full-scale prototype on the cooling tower at Wisconsin Public Service’s Fox Energy Center, a two-unit 620-MW natural gas–fired combined cycle power plant in Wrightstown, Wisconsin. According to NETL, that project will inform any potential next steps for technology maturation, paving the way to commercialization.

“If successful, the technology that is developed could lead to significant water savings and improve water quality with minimal energy cost,” the lab said. “Existing towers can be easily retrofitted with the technology, leading to a significant reduction in water usage in cooling towers as well as a reduction in chemical use for water treatment in coal plants.”

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).