Gas

-

Coal

CERAWeek 2009: Floundering Economy Eclipses Renewable, Carbon Plans

For the past 26 years, Cambridge Energy Research Associates (CERA) has hosted an annual conference in Houston that is world-renowned for its high-profile speakers and attendees’ willingness to exchange ideas and share industry forecasts. The consensus this year was that the power industry remains strong but market and political forces, often working at cross-purposes, make bringing any new power generation to market more problematic than ever.

-

Coal

Fossil Fuels + Solar Energy = The Future of Electricity Generation

Renewable energy, though still accounting for a comparatively small portion of overall supply, generates a larger portion of the world’s electricity each year. Combining many of the available solar energy conversion technologies with conventional fossil-fueled technologies could reduce fuel costs while simultaneously helping utilities that are struggling to meet their renewable portfolio goals.

-

Coal

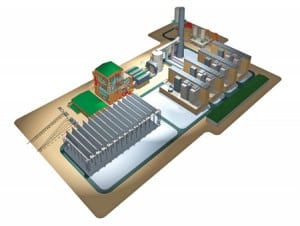

Sri Lanka Commissions Major Thermal Power Plant

The Sri Lankan government in December commissioned the first phase of the 300-MW Kerawalapitiya Thermal Power Plant, the nation’s biggest combined-cycle power plant project. The $300 million plant in the western part of the country commenced operations by generating 200 MW (Figure 7). In its second phase, it will expand to 300 MW. Per government estimates, power produced by the plant is priced at about 20 rupees or $0.18/kWh.

-

Gas

2009 Industry Forecast: New Power Politics Will Determine Generation’s Path

The U.S. power industry’s story in 2009 will be all about change, to borrow a now-familiar theme. Though the new administration’s policy specifics hadn’t been revealed as POWER editors prepared this report, it appears that flat load growth in 2009 will give the new administration a unique opportunity to formulate new energy policy without risking that the lights will go out.

-

O&M

Stopping Natural Gas Leaks

Chances are you have endured the tedious process of removing fuel piping when maintaining just about any gas turbine, especially aero-derivative engines that are usually swapped out rather than repaired in place. One of the most time-consuming jobs after reassembling the fuel piping is checking for leaks at all the flanges. In a large frame-size turbine, that means sealing up to 64 flanges and then removing the seals after the leak testing.

-

Gas

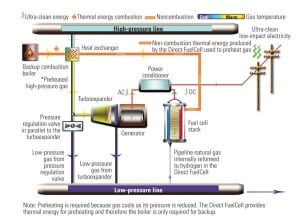

Ontario turbine gets pressure from natural gas pipelines

Enbridge Inc., a Canadian pipeline and energy distribution and services company, and FuelCell Energy Inc. opened what they say is the "world’s first" direct fuel cell – energy recovery generation (DFC-ERG) power plant in Toronto, Ontario, this October. The innovative 2.2-MW project harvests high pressure that is used to channel natural gas over long distances […]

-

Coal

Under construction in South Africa

This summary of power generation projects is a web-only supplement to the November 2008 special report titled “Whistling in the dark: Inside South Africa’s power crisis.”

-

Commentary

How unconventional fields are powering Texas

In the 1980s, Houston wildcatter George Mitchell drilled the first well into the Barnett Shale formation that stretches through north and central Texas. He tapped into what would turn out to be one of the most prolific and valuable onshore natural gas reserves in the United States.

-

Gas

Bugok II Power Plant, Dangjin County, South Korea

South Korea, one of the “Four Asian Tigers” known for their aggressive economies, is boosting its electrical capacity with the recent addition of the Bugok II Power Plant. Ranked as the top plant in South Korea because of its efficient, environmentally friendly operation, the 565-MW plant is powered by combined-cycle units that burn natural gas. Part of this project’s success derives from the fact that Bugok I and II were the first projects awarded to a foreign company by a South Korean independent power producer.

-

Gas

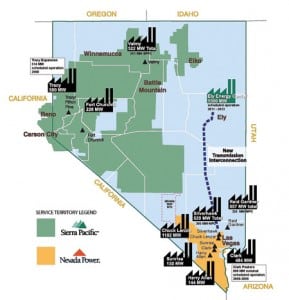

Frank A. Tracy Combined Cycle Plant, Reno, Nevada

At 564 MW, Sierra Pacific Resources’ Frank A. Tracy Combined Cycle Plant is the largest power project constructed in northern Nevada in 24 years and will reduce the state’s dependence on expensive power purchases from out-of-state suppliers. The project achieved a significant safety milestone by expending 1.5 million safe work hours during construction with zero lost-time accidents.

-

Gas

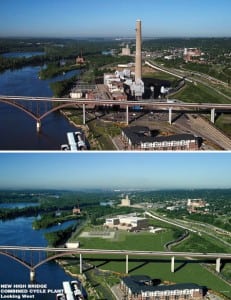

High Bridge Combined Cycle Project St. Paul, Minnesota

With greenhouse gas caps on the horizon, more U.S. utilities now have another reason–besides tightening air pollution limits–to consider replacing some of their old coal-fired plants with less-carbon-intensive gas-fired capacity. Even local residents are pleased with the results of an Xcel Energy project to do just that in St. Paul, Minnesota. For Xcel, the key ingredient in the recipe for its recently commissioned High Bridge plant was hiring an EPC contractor smart enough to overcome formidable site constraints.

-

Gas

Kårstø Power Plant, Stavanger, Norway

Power supplies are looking brighter these days in the Land of the Midnight Sun now that the Kårstø combined-cycle power plant has begun commercial operation. Kårstø is Norway’s first commercial onshore gas-fired combined-cycle plant. Combining Scandinavian savvy with German engineering, this 420-MW plant showcases maximum efficiency coupled with minimal emissions.

-

Gas

Port Washington Generating Station, Phase 2, Port Washington, Wisconsin

We Energies’ Port Washington Generating Station Phase 2 is recognized as a 2008 POWER Top Plant for its design innovation and strong teamwork among the owner, contractor, and craft personnel that ensured project completion on time, on budget, and with a stellar safety record. While staying true to its historical roots, the plant will remain a good neighbor and a reliable provider of intermediate-load power to the region for many years to come.

-

Coal

Global Monitor (July 2008)

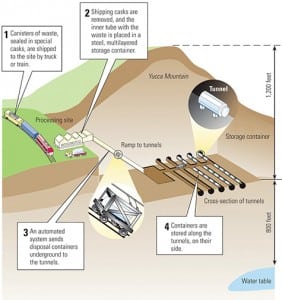

Yucca Mountain plan sent to NRC/ CPV cells get cooling chips from IBM/ StatoilHydro to pilot test first offshore floating wind turbine/ U.S. rivers next massive power source?/ Siemens delivers 500-MW gasifiers/ Algae: A green solution/ POWER digest

-

Coal

Woods and power company CEOs agree: “The state of the industry is cautious”

It is rare indeed to witness, at an otherwise staid industry forum, the public rebuke of the country’s most prominent supplier to the electric power industry. But at the Keynote session and Power Industry CEO Roundtable of the 2008 ELECTRIC POWER Conference & Exhibition in Baltimore this May, Milton Lee, general manager and CEO of […]

-

Coal

Global Monitor (June 2008)

Artificial photosynthesis for solar power? / Poultry litter to fuel 55-MW N.C. plan / First fuel cell-powered plane takes flight / First HTS transmission cable energized / PTC powers wind power industry / Renewing Greensburg / GAO deems coal-to-gas switch impractical / Assessing the Congo River’s power potential / POWER digest / Corrections

-

Coal

Global Monitor (April 2008)

Tenaska proposes first new coal-fired plant with carbon capture/ Concerns raised over growth of China’s CO2 emissions/ Sandia, Stirling Energy Systems set new world record/ Indonesia orders first Wärtsilä Gas Cubes/ First wind turbines on Galapagos Islands cut oil imports/ Harnessing waste heat for electricity/ POWER digest/ Correction

-

Gas

Castejon 2: Ready to reign in Spain

The new, 424-MW Castejon 2 combined-cycle plant designed and built by Alstom was recently given its provisional acceptance certificate. Alstom used its “Plant Integrator” approach to fast-track delivery of a plant just like Castejon 1, which averaged 98% availability during its first three years of operation. That kind of performance is crucial to generators operating in the Spanish merchant power market—or any market.

-

Coal

Global Monitor (March 2008)

DOE scraps FutureGen / U.S. nuclear plants have record year / Westinghouse wins TVA contract / UniStar Nuclear to file for COL / AEP ranks second in U.S. construction / China moving to the driver’s seat / New solar cycle poses risks / Dutch favor power from natural gas / POWER digest / Corrections

-

Gas

How to make a power plant a welcome neighbor

Developing power projects has become less a technical challenge and more an exercise in developing good relationships among all the stakeholders. If a community understands the need for a new plant and is involved in its development process, the odds of a successful project increase.

-

O&M

Desuperheating valves take the heat

Hot reheat steam bypass actuators are some of the most critical, yet least understood components in a typical combined-cycle plant. If you’re using pneumatic actuators to stroke your main steam or hot reheat bypass valves in a cascading bypass system, you’re behind the times. Here’s a way to get better control of the bypass process, shorten unit start-up and train blending times, and decrease your plant’s heat rate—all at the same time.

-

O&M

Extend EOH tracking to the entire plant

Predicting combined-cycle system longevity and determining optimal maintenance intervals at the same time is difficult: It requires balancing repair costs against the risk of trying to squeeze that last bit of life out of some component before it fails. One solution to the problem is to extend coverage of an equivalent operating hours (EOH) preventive management program for turbines to the entire plant.

-

Coal

Global Monitor (February 2008)

FutureGen picks Mattoon, Ill./Duke applies for first greenfield COL/PPL to work with UniStar on another COL

/Areva seeks NRC certification of its reactor/Mitsubishi also in line at the NRC/PV project shines in Nevada/SunEdison commissions Colorado PV plant/Big concentrating solar plant proposed/Super Boiler celebrates first anniversary/Small fuel cell uses JP-8 jet fuel/POWER digest -

O&M

The case for cathodic protection

All fossil fuels carry some risk with their reward of an energy density that’s sufficient for producing electricity economically. For coal and natural gas, that threat is a fire or explosion. However, the risk of an explosion isn’t limited to gas-fired plants. Gas poses a threat to any plant that uses the fuel, even in small quantities for heating. Here’s an overview of what you should be doing to keep gas pipelines from corroding and exploding.

-

Coal

Global Monitor (January 2008)

Dominion applies for new Virginia reactor / ABB commissions world’s largest SVC / Google Earth adds air quality data / Alstom supplies integrated solar/CC project in Morocco / DOE updates coal plant database / Dam the Red Sea? / Complying with CWA Section 316

-

Coal

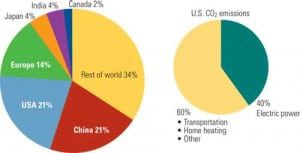

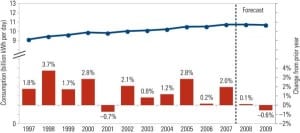

Regulatory risks paralyzing power industry while demand grows

In our second annual report on the state and future of the U.S. power generation industry, we combine the considerable experience of POWER’s editorial staff with the market savvy of Industrial Info Resources Inc. (see next story) to preview the industry’s direction in 2008. We anticipate that the specter of carbon control legislation will hobble coal and make renewables the hot ticket while nukes continue to inch forward in a generation market that is basically treading water.

-

Coal

Greater fuel diversity needed to meet growing U.S. electricity demand

Industrial Info Resources’ strengths are tracking capital projects and cost projections and providing intelligence about the power generation market, among others. IIR has used its large industry databases and numerous industry contacts to develop its outlook for 2008. Here’s what you should expect and plan for this year.

-

Gas

Global Monitor (December 2007)

TVA may revive Bellefonte / GE’s globetrotting Jenbaches / Largest PV plant taking shape / When will PV be competitive? / Siemens goes to the wall with solar / Breakthrough in metamaterials / POWER digest

-

Coal

Global Monitor (October 2007)

Siemens ships first blade from U.S. plant; GE’s frames hit 1,000; Battery problems hit hybrid EV programs; Solar thermal rebounds in California;Peabody’s Illinois coal plant gets green light;EPA could sink 278-MW CFB unit; Longest-serving NRC commissioner dies at 58; POWER digest; Readers talk back; corrections