UK Eyes 2025 Operation Date for Fusion Demo Plant as Powerful Magnet Heads to ITER

This week marked two major milestones for fusion energy. On June 15, San Diego-based General Atomics (GA) said it was ready to ship the first module of the Central Solenoid—the world’s most powerful magnet—which will become a central component of ITER, the world’s largest experimental fusion facility that is under construction in France. And a day later, Vancouver-based General Fusion announced it inked an agreement to build and operate the Fusion Demonstration Plant (FDP) at the UK Atomic Energy Authority’s (UKEA’s) Culham Campus, a project that will demonstrate its Magnetized Target Fusion (MTF) technology. Construction is slated to begin next year, and the plant could be operational by 2025.

The milestones put the promise of demonstrating the feasibility of fusion energy—an energy resource that essentially replicates the process which powers the sun—closer to fruition. They also build on tremendous momentum from the scientific community that suggests fusion energy is closer than many people realize.

Fusion energy—sometimes called nuclear fusion, though this is discouraged to avoid confusion with nuclear fission—harvests the large amount of energy released when light atomic nuclei (such as hydrogen) fuse together to form heavier ones (such as helium). To enable this “fusion,” fuel is heated to very high temperatures forming a plasma in which fusion reactions take place. Experts have long-lauded its possibilities as the perfect energy resource: Not only could it provide a virtually limitless of highly concentrated, baseload energy, generating that energy produces no greenhouse gas emissions or long-lived radioactive waste. And, the risk of accidents with a fusion plant is limited: if containment is lost, the fusion reaction simply stops.

First Central Solenoid Module Ready to Ship to ITER

One reason for the recent surge in interest is that the ITER experiment—an international undertaking involving 35 nations that are collaborating to build the largest and most powerful tokamak fusion device—is on track to begin operations in five to 10 years.

Courtesy: General Atomics

“The ITER project is the most complex scientific collaboration in history,” said Dr. Bernard Bigot, director-general of the ITER Organization, in a statement sent to POWER. “Very challenging first-of-a-kind components are being manufactured on three continents over a nearly 10-year period by leading companies such as General Atomics. Each component represents a top-notch engineering team. Without this global participation, ITER would not have been possible; but as a combined effort, each team leverages its investment by what it learns from the others.”

So far, ITER is reportedly almost 75% built. Despite the COVID-19 pandemic, the project has received several “massive first-of-a-kind components” over the past 15 months.

And now, according to GA, the first of six modules that will make up the Central Solenoid—the largest of ITER’s magnets and a component so central to the experiment that it is sometimes called the “beating heart” of the ITER machine—is ready to ship.

The Central Solenoid is so powerful, its magnetic force “is strong enough to lift an aircraft carrier 2 meters (6 feet) into the air,” GA said. “Fully assembled, [the Central Solenoid] will be 18 meters (59 feet) tall and 4.25 meters (14 feet) wide, and will weigh a thousand tons.”

The magnet will essentially induce a powerful current in the ITER plasma, helping to shape and control the fusion reaction during long pulses. Creating the magnetic fields in a tokamak requires three different arrays of magnets, GA explained. “External coils around the ring of the tokamak produce the toroidal magnetic field, confining the plasma inside the vessel. The poloidal coils, a stacked set of rings that orbit the tokamak parallel to its circumference, control the position and shape of the plasma.”

In the center of the tokamak, “the Central Solenoid uses a pulse of energy to generate a powerful toroidal current in the plasma that flows around the torus. The movement of ions with this current, in turn, creates a second poloidal magnetic field that improves the confinement of the plasma, as well as generating heat for fusion. At 15 million amperes, ITER’s plasma current will be far more powerful than anything possible in current tokamaks,” it said.

| For an in-depth look at how fusion energy works and major advances in recent years, see POWER’s June 2020 feature, “Fusion Energy Is Coming, and Maybe Sooner Than You Think.” |

GA marked its milestone after “a decade of design and fabrication” at GA’s Magnet Technologies Center in Poway, California, near San Diego, under the direction of the US ITER project, managed by Oak Ridge National Laboratory (ORNL). GA said final testing wrapped up earlier this year.

“This week it will be loaded onto a special heavy transport truck for shipment to Houston, where it will be placed on an ocean-going vessel for shipment to southern France,” it said. Five other Central Solenoid modules, plus one spare, are at various stages of fabrication, it said. Module 2 is slated to be shipped in August.

UK Could Begin Operating Fusion Demonstration Plant Within Three Years

While ITER’s collective successes are fueling optimism within the industry, some notable government entities have laid out ambitious targets to realize fusion’s feasibility. In a landmark report released last December, for example, the U.S. Department of Energy (DOE) Fusion Energy Sciences Advisory Committee (FESAC) set out a strategic pathway to achieve a low-capital-cost fusion pilot pant by 2040. And this February, the National Academies of Sciences, Engineering, and Medicine laid out recommendations for the design, construction, and operation of a fusion pilot plant that could produce power in the 2035–2040 timeframe.

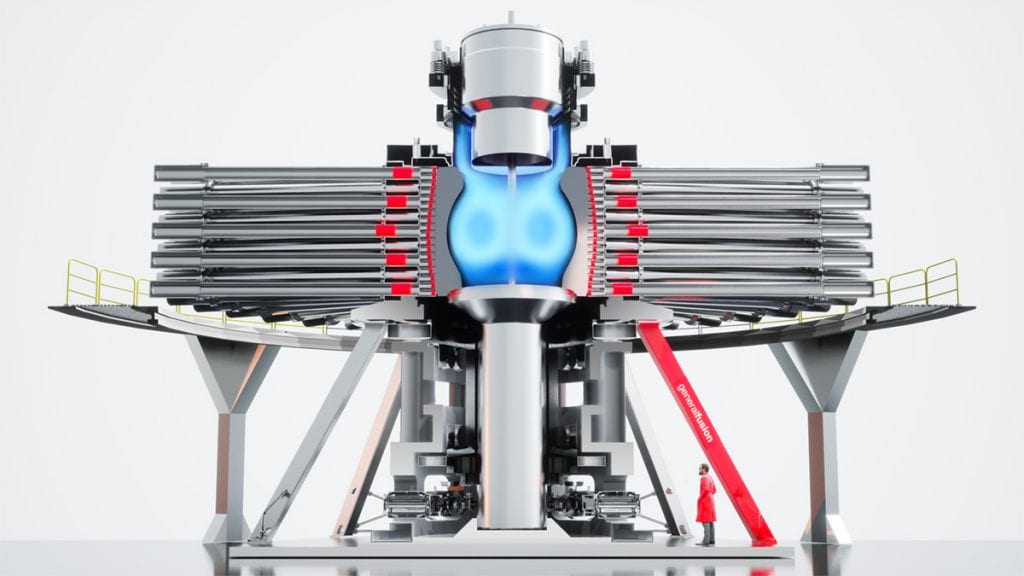

Meanwhile, across the pond in the UK, culminating more than a decade of advances in General Fusion’s proprietary Magnetized Target Fusion (MTF) technology, General Fusion and the UKAEA announced construction of the FDP at Culham will begin next year, with operations beginning “about three years later.”

A major milestone on the company’s path to commercialization, the FDP will essentially “verify that General Fusion’s MTF technology can create fusion conditions in a practical and cost-effective manner at power plant relevant scales, as well as refine the economics of fusion energy production, leading to the subsequent design of a commercial fusion pilot plant,” the entities said in a joint statement.

General Fusion’s MTF-based power plant concept involves a thick, flowing “liquid metal wall” that can absorb energy from the fusion reaction. Key to the concept is a “quasi-spherical cavity,” which is formed in the tank filled with liquid metal through a combination of fluid rotation and flow management features.

“We inject a hydrogen plasma into the cavity,” the company said. “We use high-powered pneumatic pistons to compress the plasma, increasing its density and heating it to more than 100 million C. This creates fusion conditions. Hydrogen atoms fuse and release energy in the form of heat,” it explained. That energy can then be pumped to heat exchangers. “The liquid metal also protects the solid outer wall from damage and can be combined with liquid lithium to breed tritium within the power plant,” the company noted.

Video: General Fusion: Magnetized Target Fusion Technology. Source: General Fusion

In a blog post on June 17, General Fusion CEO Christofer Mowry said that at 70% of full scale, the FDP “will be powerful enough to heat hydrogen plasma fuel to fusion temperatures of 150 million degrees.” The MTF demonstration will be key to refining “those technical performance metrics that will become the measure of our technology’s ability to economically produce energy, durably operate as a power plant, and easily follow the fluctuating demands of electricity on power grids,” he said.

If validated, the endeavor could allow the company’s customers and government partners “to proceed with commitments to jointly develop and construct the first commercial fusion pilot plants later in the 2020s,” Mowry added.

But the FDP is also notable because it will be “the first private endeavor seeking to demonstrate the ability to cost-effectively and reliably create fusion conditions in a power plant-relevant environment,” he said. That will involve gleaning key supply chain know-how and crucial construction experience.

And finally, when completed in 2025, the FDP facility “will be the stage on which General Fusion will communicate to [end-users, including customers, regulators, investors, and communities] how our MTF technology can be integrated into a new carbon-free portfolio of energy generation assets,” he said. “It will be a platform for regulators to assess licensing requirements for commercial fusion power plants. And it will become a center for convening the policymakers, community leaders, and stakeholders who are shaping this swiftly emerging future of energy in a decarbonized world.”

For UKAEA, the plant represents a “huge boost for our plans to develop a fusion industry in the UK,” said UK Science Minister Amanda Solloway. The Culham Campus, the home of the UK’s national fusion research program, is already widely recognized as “a world leader in fusion energy development and innovation,” she said.

UKAEA’s most-watched effort is perhaps its development of the STEP (Spherical Tokamak for Energy Production) program, which aims to build a prototype fusion power plant in the UK around 2040. While design work for STEP is well underway, the government in March wrapped up collecting public opinion on where to site the pioneering project. UKAEA plans to produce a “concept of design” by 2024, followed by a detailed engineering design phase, which could lead to construction within the next two decades, it said.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).