The POWER Interview: A Virtual Approach to Factory Acceptance Testing

Traditional in-person factory acceptance testing, also known as witness testing, is a challenge during a pandemic. To keep projects moving, power management company Eaton developed a virtual method to help utilities verify the capabilities of their complex equipment before it arrives onsite.

This virtual solution can provide important advantages compared to traditional witness testing, including allowing more people to participate, utilizing modern camera technology to provide up-close equipment insights, and saving time and money due to the elimination of travel. Adams Baker, product manager for low-voltage switchgear at Eaton, provided answers for POWER about how the company is using this virtual platform to help customers finalize complex equipment orders.

POWER: What’s the purpose of a factory witness test?

Baker: For electric utilities and power generation plants, witness testing, also known as a factory acceptance test (FAT), is a standard practice for major equipment like switchgear. Power distribution equipment is essential to critical infrastructure at the generation plant. So, our customers ensure that every aspect of the equipment they install meets their exacting specifications.

Much like test driving a car, witness testing can give customers added confidence for major equipment. It shows that devices communicate correctly, dashboard information displays as expected, and more. Additionally, it provides an extra opportunity to talk through safety protocols for such equipment.

Customer-attended factory witness testing is an add-on to standard testing protocols that is requested when customers desire the opportunity to become familiar with equipment prior to delivery. This type of testing is typically reserved for major equipment like low-voltage switchgear, substation switchgear and motor control centers.

Witness testing may be useful to emulate how equipment will act in its installed environment, especially when assemblies are designed for multiple power sources, complicated transfer schemes or communications, or equipment that personnel access regularly.

POWER: How is a factory witness test performed? And who goes?

Baker: Factory witness testing is not intended to ensure that equipment works, but rather provide familiarity prior to delivery. Prior to a factory witness test, all of our equipment is fully tested. At Eaton, we have standard testing protocols that are product-specific and conducted prior to and irrespective of customer-attended factory acceptance testing.

When a customer has decided that a factory witness test is desired, they’ll specify attendees. Traditionally, this has been limited to a very small team, as travel costs and time were limiting factors. With a virtual test, additional attendees can participate (Figure 1). This can include representatives from:

- Customer engineering and/or management

- Customer maintenance teams

- Consulting firms

- Electrical contractors

- Manufacturer project management

- Electrical utility representative

POWER: How does it work in a socially distant world?

Baker: With social distancing a relatively new reality, the traditional factory acceptance or witness test is a challenge. We developed a virtual model to help customers verify the capabilities of their equipment without leaving their homes or offices.

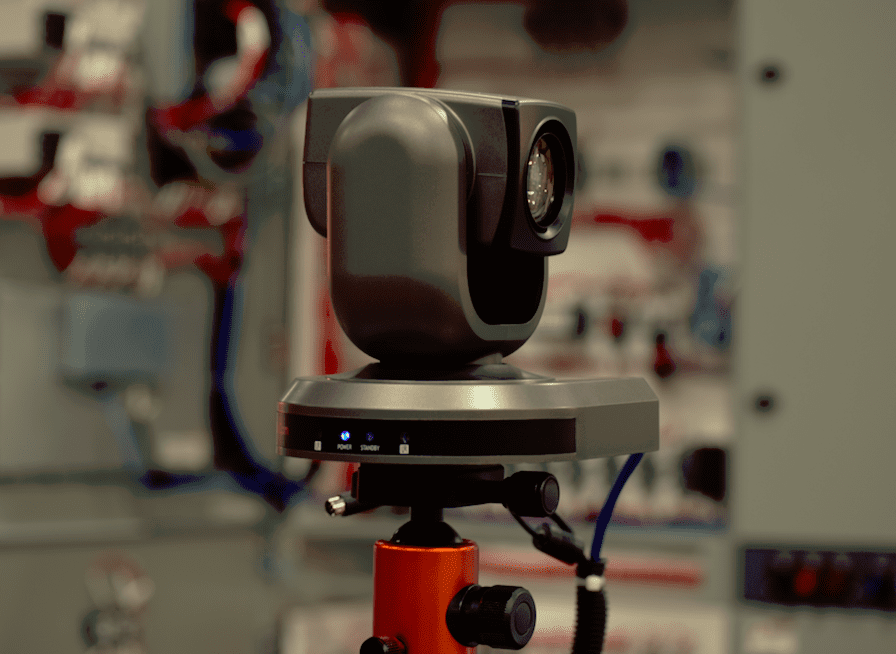

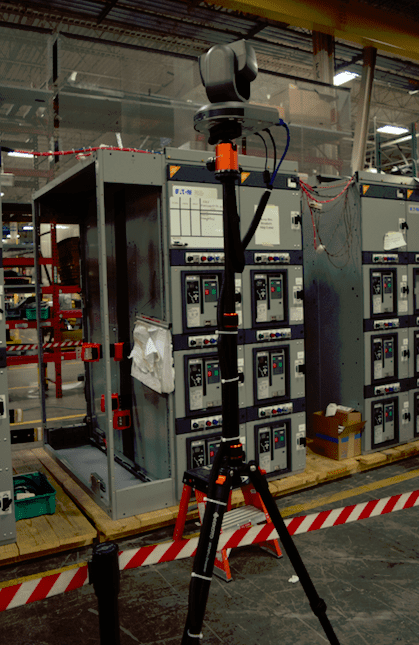

A virtual witness test works much like a traditional, in-person test. The difference is that customers are not physically on the factory floor. Equipment is energized and operational, our experts are on hand to answer questions and customers can see their equipment working. Testing occurs in real time through multiple cameras (Figure 2), complete with two-way audio, which can zoom in to clearly show nameplate data, trip unit configurations, relay function and more. It’s basically like joining a web video conference but with multiple high-definition, pan-tilt-zoom cameras that can be precisely aimed and controlled by the Eaton engineer leading the test.

POWER: What are the differences between a virtual and in-person test?

Baker: A factory witness test follows the same testing protocols and procedures whether in person or virtually. This virtual approach can provide certain advantages, including:

More people can participate remotely and better understand the equipment operation. There’s no limit on how many customer representatives can attend a virtual factory acceptance test. Further, a virtual approach is more sustainable and has a smaller carbon footprint with fewer miles traveled, no matter how many participants join the discussion.

You can get closer to equipment with a camera and see more detail. When testing electrical equipment like low-voltage switchgear in person, the equipment is energized with 480 volts and participants must be outside the arc flash boundary. Virtual tests, however, allow customers to get closer and see HMI screens, nameplate information and more while equipment is energized.

It saves time and money by eliminating travel costs and time. Also, multiple cameras can be positioned so customers can see a variety of testing aspects at one time (Figure 3).

All that said, some customers appreciate the opportunity to touch and feel the equipment (in a safe, non-energized state) to gain additional confidence on quality and craftmanship. Additionally, customers may be interested in touring our facility and observing the manufacturing process. So, some customers will still want to come into the factory when social distancing requirements are lifted. In the meantime, virtual testing provides an alternative to keep infrastructure projects on schedule.

POWER: What’s on a typical factory witness test checklist?

Baker: A virtual test is conducted much the same way a traditional test is performed. The main difference is that customers see the testing in real time via cameras instead of visiting the factory.

While the testing protocol for a factory acceptance test is product-specific, these tests provide an opportunity to see how equipment will perform in its application environment. Eaton’s testing procedure for low-voltage switchgear follows this multi-pronged approach:

- Visual—The first aspect of a factory acceptance test is a visual inspection of nameplate information, circuit breaker ratings, UL and ANSI testing labels, wiring, and more to verify everything meets the customer’s design intent.

- Mechanical operation—This aspect of the testing protocol verifies applicable key interlock systems, circuit breaker racking mechanisms and the mechanical operation of circuit breakers.

- Electrical function—The electrical circuit breaker operation is verified as well as the function of any meters and relays that may be included in the switchgear.

- Operational controls—This involves testing applicable automatic transfer systems and other operational tests to demonstrate proper sequential functions.

- As-built comparison—Check the control wiring and make sure it meets customer’s specification with respect to size, termination and general aesthetics of the layout.

A factory acceptance test gives customers an opportunity to get their eyes on equipment before it makes it to their facility. In my experience, customers typically have specific operations that they would like to verify during the test, like transferring from one power source to another or fault response.

—Darrell Proctor is associate editor for POWER (@POWERmagazine).