Inventory Management Systems: How Automation Can Save Time and Reduce Costs for Power Companies

Inventory management can provide significant operational benefits for power companies. From forecasting, fueled by real-time data, to automated replenishment and supply chain continuity, digital solutions are improving processes and productivity.

Traditional vendor managed inventory (VMI) programs track ordering, fulfillment, and replenishment of power generation equipment components and supporting pieces, but a genuinely automated end-to-end system is much more significant in scope and benefits than just “managing parts.” Modern inventory management offers a strategy that elevates supply chain assurance, increases facility efficiency, and positively impacts financial performance. These tech-enabled processes also enhance supplier-distributor collaboration and align both partners by:

- ■ Illuminating and adapting to changes in demand.

- ■ Offering visibility into consumption patterns, on-hand inventory, and locations.

- ■ Providing data to optimize quantity, logistical, and delivery decisions.

- ■ Automating replenishment based on individual facility requirements.

Digitized inventory management ensures you can make data-driven decisions with current inventory numbers that are not vulnerable to mistakes, tardiness, miscommunication, or multiple data sources. In turn, automated solutions can help you more accurately anticipate stock levels required and bring your supply chain planning into focus.

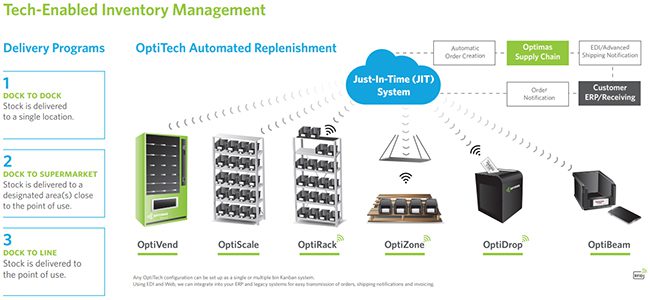

Still, some power generation companies cling to their legacy inventory management processes. Familiarity breeds comfort, but remaining loyal to those routines is likely doing you few favors. Before embarking on a new solution, it’s best to get more acquainted with what fully integrated inventory management can look like (Figure 1), how a digitized system reduces cost, and some small steps to get started.

|

|

1. A step-by-step representation of a proper end-to-end inventory management system. This chart shows Optimas’ innovative OptiTech Inventory Management Solutions that uses the latest technology to automate inventory replenishment, saving companies time and money. Courtesy: Optimas Solutions |

Tech-Enabled Inventory Management Defined

Managed inventory employs a partner (think full-service distributor) that’s responsible for all things related to inventory. This resource develops a custom program to ensure stocking levels match demand and inventory is delivered when needed. It’s about streamlining your supply chain, reducing costs, having higher visibility into your parts consumption, and reallocating human resources away from slow, manual, error-prone work to more quality-focused, value-add responsibilities. Partner requirements include:

- Digital Tools to Meet Individual Plant Requirements. The ability to easily implement technology solutions that meet different workflow and space requirements at one or multiple facilities.

- Radio Frequency Identification (RFID) and Electronic Data Interchange (EDI). Proven transmission protocols that assure the partner’s network and support data flow freely and securely to and from storage and distribution locations.

- Integration into Existing Enterprise Resource Planning (ERP) and Supply Chain Management (SCM) Platforms via Web Tools. It’s critical to ensure all aspects of production are working with the same data through a single source of truth.

- Security. All data transactions moving between the manufacturer and the partner must be secure and can’t be compromised.

- Accountability at the Facility, Group, and Individual Levels. The partner should demonstrate multiple ways to understand and attribute inventory usage.

- Reporting. Visibility throughout the managed inventory process starts with good reporting that is designed to meet an end-user’s unique needs.

- Control. The partner needs to demonstrate that manual inventory practices can be moved to automated replenishment processes at a pace that’s comfortable for the company and personnel.

How a Digitized System Helps Cut Costs

An Industrial Machinery Digest study found that most companies devote 20% to 40% of their overall working capital to inventory. With such a sizable percentage of funds invested in inventory, keeping those costs down is critical to maintaining cash flow. Automated inventory management facilitates better stocking levels, less excess and obsolete (E&O) inventory, greater control over cash flow, and fewer people needed to manage stock. A tech-enabled solution can reduce costs in many ways and power companies are starting to understand that. Among the benefits are:

- Better Forecasting Through Technology. Using RFID technology to manually or automatically submit replenishment orders means that inventory may be monitored in real-time. As a result, procurement and supply chain professionals can manage inventory levels to production requirements.

- Working Smarter with Business Analytics. Technology available today allows you to capture and use data and modeling based on real-time and historical consumption patterns. The best forecasting uses a mix of quantitative (such as past numerical insights and current market demand) and qualitative data (such as market trends, product lifecycle, competitive landscape, etc.) to guide more accurate inventory management decisions. This foresight allows decision-makers to see where demand and usage come from, and plan accordingly. You can see where fulfillment levels are and adjust production up or down based on demand, parts availability, and lead time.

- Refocusing Human Capital. With a manual scanner or an automated replenishment program, it will take less time, teammates, and process to maintain appropriate inventory levels. These productivity gains drive soft costs down and offer an opportunity to reallocate people to roles with greater impact on production.

Automating Your Inventory Management System

To get started, identify the core pain points of your current solution and map them to the benefits a digitized system provides. Here are the top five questions to ask:

- ■ On a scale of 1 to 10 (with 10 being the best) how accurate are your part counts?

- ■ How long does it take to go from count to replenishment?

- ■ Has production slowed or stopped because of low inventory or stockouts in the last 12 months? If so, was the plan to elevate production to the planned level successful?

- ■ Has E&O inventory negatively impacted your company’s balance sheet in the last three years?

- ■ Is your current supplier doing anything to improve your inventory management process?

Answers to these questions are a first step toward achieving the benefits associated with a modern inventory management solution. Digitized inventory management can make your supply chain more efficient and resilient to disruptions, develop higher visibility into your part consumption, improve forecasting, and help you reallocate resources to more productive responsibilities.

|

|

2. This graphic shows the multiple technology options at your fingertips with Optimas’ OptiTech Inventory Management Solutions. Courtesy: Optimas Solutions |

Tech-enabled inventory management (Figure 2) has promising benefits for the global power generation industry. Among them are savings in time from a labor and administrative standpoint, increased supply chain assurance, and greater confidence in data-driven decisions. Today’s supply chain solutions and the right partner to plan, implement, report, and fulfill orders can elevate efficiencies and help companies be more competitive in a very demanding marketplace.

—Paul Przyby is senior vice president of Sales and Marketing with Optimas Solutions.