Global Monitor (April 2008)

Tenaska proposes first new coal-fired plant with carbon capture

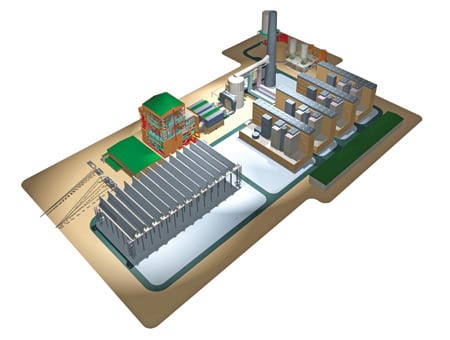

Tenaska Inc. is developing a site near Sweetwater, Texas, for a new 765-MW gross, 600-MW net supercritical coal-fired power plant that will capture up to 90% of the CO2 in the stack gas. The captured CO2 will to be used in enhancing oil production in the Permian Basin. The proposed construction site for the $3 billion Trailblazer Energy Center is a 1,919-acre tract east of Sweetwater and north of Interstate 20 in Nolan County. Construction could begin in late 2009 and be completed in 2014 (Figure 1).

1. First out of the gate. Tenaska has proposed the first coal-fired supercritical power plant with integrated CO2 capture. Source: Tenaska Inc.

If built, the plant will be the first new commercial coal-fueled power plant, other than small research projects, to capture and provide for storage of CO2. The CO2 would be captured and transported via pipeline to oil fields in the Permian Basin, where it will be used in enhanced oil recovery and be stored in the basin’s geologic formations. CO2 has been used to increase oil production in West Texas for more than 30 years (Figure 2).

2 Bury it deep. Captured CO2 from the Trailblazer Energy Center will be used for enhanced oil recovery in the Permian Basin. Source: Tenaska Inc.

The volume of CO2 expected to be sold to oil producers could be used to recover enough oil to add more than $1 billion a year to the Texas economy.

“Nolan County is home to more wind turbines than any other place in the United States,” said Nolan County Judge Tim Fambrough. “The Tenaska Trailblazer Energy Center builds on this area’s reputation as a location for progressive, environmentally responsible electric generation. We are delighted to welcome Tenaska to our community.”

An air permit application, the first formal step in gaining approval to build the plant, was filed in early March with the Texas Commission on Environmental Quality, according to David Fiorelli, president and CEO of Tenaska’s Business Development Group.

The final decision to proceed with the project will be made in 2009 based on a number of factors, including the availability of local, state, and federal incentives; final project cost estimates; and projected market prices for electricity and CO2. Current estimates of these factors make the project appear to be economically feasible. In the meantime, Tenaska is working with Sweetwater area officials to determine the project’s feasibility and to provide accurate and timely information to Sweetwater area residents.

Concerns raised over growth of China’s CO2 emissions

The growth in China’s CO2 emissions is far outpacing previous estimates, making the goal of stabilizing atmospheric greenhouse gases even more difficult, according to a new analysis by economists at the University of California, Berkeley and UC San Diego. The study is scheduled for print publication in the May issue of the Journal of Environmental Economics and Management.

Previous estimates, including those used by the Intergovernmental Panel on Climate Change, say the region that includes China will see a 2.5% to 5% annual increase in CO2 emissions between 2004 and 2010. The new UC analysis pegs China’s annual growth rate at 11%, at a minimum, for the same time period. In contrast, the U.S. Energy Information Administration reports U.S. CO2 emissions decreased 1.3% in 2006 from the previous year. Data for 2007 is not yet available.

The researchers’ most conservative forecast predicts that by 2010 there will be an increase of 600 million metric tons of carbon emissions in China over the country’s levels in 2000. This growth from China alone would dramatically overshadow the 116 million metric tons of carbon emissions reductions pledged by all the developed countries in the Kyoto Protocol and surpassed those of the U.S. last year.

Put another way, the projected annual increase in China alone over the next several years is greater than the current emissions produced by either Great Britain or Germany.

The authors pointed out that after 2000, China’s central government began shifting the responsibility for building new power plants to provincial officials, who had less incentive and fewer resources to build cleaner, more efficient plants, which save money in the long run but are more expensive to construct. Government officials turned away from energy efficiency as an objective to expanding power generation as quickly and cheaply as they could. Wealthier coastal provinces tended to build clean-burning power plants based upon the very best technology available, but many of the poorer interior provinces replicated inefficient 1950s Soviet technology.

Sandia, Stirling Energy Systems set new world record

On a perfect New Mexico winter day—with the sky almost 10% brighter than usual—Sandia National Laboratories and Stirling Energy Systems (SES) set a new solar-to-grid system conversion efficiency record by achieving a 31.25% net efficiency rate. The old 1984 record of 29.4% was toppled January 31 by SES’s “Serial #3” solar dish Stirling system at Sandia’s National Solar Thermal Test Facility (Figure 3).

3. For the record books. Sandia and Stirling Energy Systems set a new world record for solar-to-grid conversion efficiency of 31.25%, eclipsing the old record of 29.4% that had stood for 24 years. Courtesy: Sandia National Laboratory, Photo by Randy Montoya

The conversion efficiency is calculated by measuring the net energy delivered to the grid and dividing it by the solar energy hitting the dish mirrors. Auxiliary loads, such as water pumps, computers and tracking motors, are accounted for in the net power measurement.

“Gaining two whole points of conversion efficiency in this type of system is phenomenal,” said Bruce Osborn, SES president and CEO. “This is a significant advancement that takes our dish engine systems well beyond the capacities of any other solar dish collectors and one step closer to commercializing an affordable system.”

Serial #3 was erected in May 2005 as part of a prototype six-dish model power plant at the Solar Thermal Test Facility that produces up to 150 kW of grid-ready electrical power during the day. Each dish unit consists of 82 mirrors arranged in a dish shape to focus sunlight into an intense beam.

The solar dish generates electricity by focusing the sun’s rays onto a receiver, which transmits the heat energy to a Stirling engine. The engine is a sealed system filled with hydrogen. As the gas heats and cools, its pressure rises and falls. The change in pressure drives the pistons inside the engine, producing mechanical power, which in turn drives a generator and makes electricity.

Lead Sandia project engineer Chuck Andraka says that several technical advancements to the systems made jointly by SES and Sandia led to the record-breaking solar-to-grid conversion efficiency. SES owns the dishes and all the hardware. Sandia provides technical and analytical support to SES in a relationship that dates back more than 10 years.

Andraka says the first and probably most important advancement was improved optics. The Stirling dishes are made of a low-iron glass with a silver backing that make them highly reflective—focusing as much as 94% of the incident sunlight on the engine package, whereas prior efforts reflected about 91%. The mirror facets, patented by Sandia and Paneltec Corp. of Lafayette, Colo., are highly accurate and have minimal imperfections in shape.

Both improvements allow for the loss-control aperture to be reduced to 7 inches in diameter—meaning that light is highly concentrated as it enters the receiver. Other advancements to the solar dish–engine system that helped Sandia and SES beat the energy conversion record were a new, more effective radiator that also costs less to build and a new high-efficiency generator.

The temperature on the record-setting date, which hovered around freezing, allowed the cold portion of the engine to operate at about 73F, and the sky’s brightness meant that more energy was produced while most parasitic loads and losses were constant. The test ran for two and a half hours. A 60-minute running average was used to evaluate the power and efficiency data, in order to eliminate transient effects. During the testing phase, the system produced 26.75 kW, net.

SES is working to commercialize the record-performing system and has signed power purchase agreements with two major southern California utilities (Southern California Edison and San Diego Gas & Electric) for up to 1,750 MW, representing the world’s two largest solar power contracts. Collectively, these contracts require up to 70,000 solar dish–engine units.

Indonesia orders first Wärtsilä GasCubes

In December 2007, Wärtsilä got its first order for a Wärtsilä GasCube power plant. PT PLN (Persero) Wilayah Kalimantan Timur, a regional subsidiary of the Indonesian state-owned utility company PT Perusahaan Listrik Negara (PLN) (Persero), ordered two GasCubes for a single site in Bontang in the province of East Kalimantan.

Both plants incorporate a Wärtsilä 16V34SG gas engine rated at 7 MW (Figure 4). The two GasCubes are due to be handed over in March 2009. They will run on locally available natural gas to generate electricity for the national grid. The GasCubes were selected because of their high generating efficiency and small footprint.

4. Thinking inside the box. The Wärtsilä GasCube is a complete single-engine power plant with all the ancillaries and components needed to form a working power production unit. Courtesy: Wärtsilä

The Wärtsilä GasCube is a standardized power plant that provides industrial customers, utilities, and independent power producers with economical, reliable, and quickly installed capacity of 7 to 26 MW on a turnkey basis.

Each GasCube is a complete single-engine power plant with all the ancillaries and components needed to form a working power production unit. Each plant is of cubical construction with radiators on the roof and an exhaust gas stack close to the Cube. The GasCube is based on Wärtsilä 34SG engines and can provide up to 9 MW. All components and structures are above ground.

The exhaust silencer and stack are integrated, thereby reducing the plant’s footprint. The small footprint and minimum interface with the surrounding environment open up new possibilities for placing the GasCubes. A closed-circuit cooling system that reduces water consumption to a minimum makes the plant perfectly suitable for remote locations or any location where water is scarce.

First wind turbines on Galapagos Islands cut oil imports

In January 2001, the world held its breath when the tanker Jessica, loaded with 150,000 gallons of fuel, struck a reef and began breaking up in the heart of one of the most precious, famous, and fragile ecosystems on Earth—the Galapagos Islands. At risk were vast numbers of unique species of flora and fauna written about by Charles Darwin in studies that contributed to his landmark theory of evolution by natural selection.

The sight of thousands of gallons of oil pouring into the ocean off the Galapagos island of San Cristobal triggered a determined international initiative to mitigate risks of future spills by dramatically reducing the islands’ dependence on diesel fuel to generate electricity.

Ecuador’s President Rafael Correa just launched his country’s program to end the use of fossil fuels on the Galapagos by 2015. That initiative is led by the San Cristobal Wind Project: three giant wind turbines that will halve the island’s diesel fuel imports and pave the way for further renewable energy development elsewhere in the archipelago (Figure 5).

5. Evolving power supply. Ecuador recently dedicated three wind turbines on the Galapagos Islands that will supply approximately half of the residents’ power demands. Courtesy: e8

The three wind turbines, totaling 2.4 MW, were installed by the San Cristobal Wind Project, an international partnership among the government of Ecuador, the UN Development Program (UNDP), and nine of the world’s largest electricity companies (known as the e8). They started supplying power on the islands last October. The system will meet 60% to 80% of electrical demand during the windy months of October, November, and December.

The San Cristobal Wind Project is the first stage of an umbrella program supported by Ecuador and the UNDP that will eventually bring renewable electricity—hybrid wind-diesel with some photovoltaic power—to the 30,000 residents of the Galapagos archipelago’s five inhabited islands.

The lead company in the project’s development, funding, and implementation was American Electric Power (AEP), which provided about half of the $10.8 million needed. Ecuador provided $3.2 million, and $1 million came from the United Nations Foundation, coupled with contributions from the UNDP and other sources. A trust has been established to facilitate the system’s ongoing training needs, maintenance and operation, and eventual removal.

“From day one, the overriding concern was the need to protect this invaluable place and its incredible biodiversity,” said Michael G. Morris, CEO of AEP. “The e8 team approached this work with a level of caution akin to the curators responsible for da Vinci’s Mona Lisa or Michelangelo’s David.”

According to project manager Luis Vintimilla of EOLICSA, the company established to operate the project, it is not possible to replace all diesel generation capacity with wind power. “That would be ideal, but there is not enough wind year round,” he said. “In particular, during four months of the year with unfavorable wind conditions, during certain hours on certain days, it will be necessary to continue using diesel generated electricity. However, it is recommended that future work be done on projects to substitute the diesel currently used with a more environmentally friendly fuel.”

Harnessing waste heat for electricity

Energy now lost as heat during the production of electricity could be harnessed through the use of silicon nanowires synthesized via a technique developed by researchers with the U.S. Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab) and the University of California (UC) at Berkeley. The far-ranging potential applications of this technology include the DOE’s hydrogen fuel cell–powered “Freedom CAR” and personal power-jackets that could use heat from the human body to recharge cell phones and other electronic devices.

“For example, if it is cold outside and you are wearing a jacket made of material embedded with thermoelectric modules, you could recharge mobile electronic devices off the heat of your body [Figure 6],” explained Arun Majumdar, a mechanical engineer and materials scientist with joint appointments at Berkeley Lab and UC Berkeley. “In fact, thermoelectric generators have already been used to convert body heat to power wrist watches.”

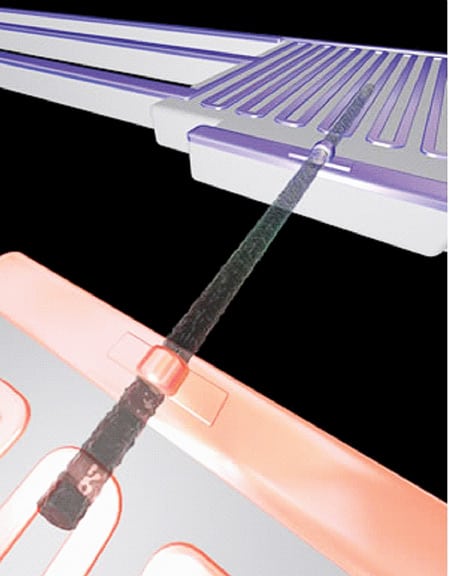

6. Nano generators. Rough silicon nanowires demonstrated high-performance thermoelectric properties even at room temperature when connected between two suspended heating pads. Here, one pad serves as the heat source (pink) and the other as the sensor. Source: Lawrence Berkeley National Laboratory

“We’ve shown that it’s possible to achieve a large enhancement of thermoelectric energy efficiency at room temperature in rough silicon nanowires that have been processed by wafer-scale electrochemical synthesis,” said chemist Peidong Yang, the other principal investigator behind this research, who also holds joint Berkeley Lab and UC Berkeley appointments.

The researchers describe a unique “electroless etching” method by which arrays of silicon nanowires are synthesized in an aqueous solution on the surfaces of wafers that can measure dozens of square inches in area. The technique involves the galvanic displacement of silicon through the reduction of silver ions on a wafer’s surface. Unlike other synthesis techniques, which yield smooth-surfaced nanowires, this electroless etching method produces arrays of vertically aligned silicon nanowires that feature exceptionally rough surfaces. The roughness is believed to be critical to the surprisingly high thermoelectric efficiency of the silicon nanowires (Figure 7).

7. Miracle fibers. A cross-sectional scanning electron microscope image of an array of rough silicon nanowires includes an inset showing a typical wafer chip of these wires (a). The second photograph is a transmission electron microscope image of a segment of one of these wires in which the surface roughness can be clearly seen. The inset shows that the wire is single-crystalline all along its length. Source: Lawrence Berkeley National Laboratory

“Thermoelectric materials, which have the ability to convert heat into electricity, potentially could be used to capture much of the low-grade waste heat now being lost and convert it into electricity,” said Majumdar. “The same devices can also be used as refrigerators and air conditioners, and because these devices can be miniaturized, it could make heating and cooling much more localized and efficient.”

The ability to dip a wafer into solution and grow on its surface a forest of vertically aligned nanowires that are consistent in size opens the door to the creation of thermoelectric modules that could be used in a wide variety of situations. For example, such modules could convert the heat from automotive exhaust into supplemental power for a vehicle, or provide the electricity a conventional vehicle needs to run its radio, air conditioner, and power windows.

When scaled up, thermoelectric modules could eventually be used for cogenerating power with gas or steam turbines. “You can siphon electrical power from just about any situation in which heat is being given off, heat that is currently being wasted,” said Majumdar.

The Berkeley Lab researchers will be studying the physics behind this phenomenon to better understand and possibly manipulate it for additional improvements. Berkeley Lab’s Technology Transfer Department is now seeking industrial partners to further develop and commercialize this technology.

POWER digest

News items of interest to power industry professionals.

CO2 capture demo. Basin Electric Power Cooperative and Powerspan Corp. announced the selection of Powerspan’s CO2 capture technology for a commercial demonstration at Basin Electric’s coal-based electrical generation facility, the Antelope Valley Station located near Beulah, North Dakota. (For more details on the Powerspan CO2 removal technology, see POWER October 2007, p. 54.)

Approximately one million tons of CO2 will be captured annually from the 120-MW slipstream project, making this demonstration among the largest in the world. The captured CO2 will be fed into an existing CO2 compression and pipeline system owned by Basin Electric’s wholly owned subsidiary, Dakota Gasification Co.

IGCC plant gets regulator nod. Going boldly where some states have feared to tread, the Public Service Commission of West Virginia gave its approval to American Electric Power Co.’s plans to build a 629-MW IGCC coal power plant at the site of AEP’s existing Mountaineer plant near New Haven, W.V.

With the approval, AEP becomes the second utility to have been given the go-ahead by state regulators to build a commercial-scale power plant using IGCC technology that remains commercially unproven for power plant applications.

Duke Energy Corp.’s application to build a 630-MW IGCC plant was approved by the Indiana Utility Regulatory Commission in November. Both Duke and AEP still need to secure air permits before they can begin construction of their respective projects.

Regulators in other states have balked at IGCC plants because of the technical uncertainties and fears about saddling ratepayers with high development costs.

The AEP project’s cost, now estimated to be about $2.23 billion, has nearly doubled since the Columbus, Ohio–based company announced it in 2004. The heavy cost increases are due to sharp price increases in steel, cement, and other construction necessities—fueled in part by China’s burgeoning economy.

DOE refuses to reconsider corridors. The DOE has refused requests by state and local officials, environmentalists, and affected community groups to reexamine the parameters of its two “national interest electric transmission corridors,” thus clearing the way for utilities to seek federal override of state and local opposition to new power lines located in those DOE- designated areas in the Southwest and Mid-Atlantic.

While acknowledging state and local concerns about federal intervention in power line siting decisions, the DOE said it was carrying out directives from Congress in the Energy Policy Act of 2005, which required the department to establish the corridors and granted the Federal Energy Regulatory Commission “backstop” authority to approve power lines in those corridors that are blocked by state and local officials.

The department also said that in drawing the national interest transmission corridors, it relied on clear evidence that there was transmission congestion in the designated areas and that new power lines were needed to meet growing electricity demand in those energy-constrained regions.

The DOE also rejected a welter of arguments from critics who said that it had failed to consult adequately with states in setting the transmission corridors, as required by Congress; that it violated federal administrative law by failing to provide enough time for public comment on its proposed corridors; that it violated federal environmental review requirements; and that it had relied too heavily on CRA International, a contractor, in assessing transmission congestion (New York officials contended that CRA studies gave too much weight to electric utility industry views).

In what could be a focus of legal challenges to the DOE, the department asserted that it did not have to follow federal administrative procedure because its action on the corridors was an “informal adjudication.” Lawsuits to follow.

Florida blackout caused by engineer error. In what it called preliminary findings of an ongoing investigation into the blackout, Florida Power & Light Co. (FPL) said an engineer working on a switch malfunction at a west Miami substation turned off “two levels of relay protection,” allowing the fault to ripple through the grid, resulting in the loss of power for 2.5 million Floridians in late February.

The company’s announcement appears to answer a key question asked by federal officials and investigators with the North American Electric Reliability Corp.: Why wasn’t the small short-circuit at the substation quickly isolated by protective devices so it did not spread?

“While still preliminary, the results of the investigation so far indicate that human error was the primary factor immediately responsible for the event,” FPL said in a press release.

“A field engineer was diagnosing a switch that had malfunctioned at FPL’s Flagami substation in West Miami,” the utility said. “Without authorization, the engineer disabled two levels of relay protection. This was done contrary to FPL’s standard procedures and established practices. Standard procedures do not permit the simultaneous removal of both levels of protection.

“During the diagnostic process, a fault occurred and, because both levels of relay protection had been removed, caused an outage ultimately affecting 26 transmission lines and 38 substations. One of the substations affected serves three of the generation units at Turkey Point, including a natural gas unit as well as both nuclear units, which, as designed, automatically and safely shut down due to an under-voltage condition. Also affected were two other generation plants in FPL’s system. Total impact to the system was a loss of 3,400 MW of generating capacity.”

H-Engine achieves first firing in Japan. GE Energy’s first commercial H System gas turbine has achieved first firing at Tokyo Electric Power Co.’s Futtsu Thermal Power Station. Tepco Futtsu is the first commercial site for GE’s most advanced gas turbine combined-cycle system.

Futtsu Thermal Power Station will feature three H Systems, each including GE Energy’s 9H gas turbine along with a steam turbine and generator provided by Toshiba under an agreement with GE. The three combined-cycle blocks will enter commercial operation between 2008 and 2010, with a total output of 1,520 MW.

Futtsu Thermal Power Station is the second location where GE Energy’s H System gas turbine will be in operation. The world’s first 50-Hz 9H combined-cycle system entered service in 2003 at Baglan Bay in South Wales and has surpassed 26,500 operating hours. The first 60-Hz project is the Inland Empire Energy Center in California, scheduled to begin service later this year.

CO2 capture partnership formed. Alstom and The Dow Chemical Co. (Dow) announced a joint development and commercialization agreement for advanced amine scrubbing technology for the removal of CO2 from low-pressure flue gases particular to fossil fuel–fired power plants and other major industries. The agreement between Alstom and Dow is worldwide and exclusive for the application of this specific technology (see POWER, February 2008, p. 38 for a description of the process).

Under the agreement, Alstom will commercialize and manage the installation of carbon capture solutions using the developed process. Dow, a global gas treatment technology leader, will support Alstom by leveraging its technical capabilities to co-develop an optimized CO2 capture system.

Panda Energy to build 500-MW plant. Panda Energy Inc. has announced that it intends to build, own, and operate a 500-MW combined-cycle power plant in an industrial-zoned area of the city of Sherman, Texas. The Panda Sherman generating station will be located on a 200-acre site at the Progress Industrial Park. Construction will take approximately 24 months and is dependent upon financing, regulatory approvals, and other conditions. Panda Energy previously announced that it has filed for an air permit to build a 1,000-MW combined-cycle power plant in Temple, Texas.

Peru gets two gas turbines. Siemens Power Generation has awarded Worley- Parsons the engineering phase contract for installation of two SGT6-5000F simple-cycle units in Peru. The first unit is the Simba Project for EnerSur, a subsidiary of Suez Energy International. That project is located in Chilca, 37 miles south of Lima. The second installation is the Kallpa Unit II Project for Kallpa Generacion S.A., where Siemens previously installed a SGT6-5000F unit. The two project sites are less than a mile from each other. Worley-Parsons’ Chattanooga office design team, with support from ARA WorleyParsons in Chile, will complete both projects on an economically structured concurrent basis. The projects are scheduled for completion in July 2008.

Superconducting wire goes live. SuperPower Inc. has reconnected the 350-meter high-temperature superconducting (HTS) cable to the National Grid power system between the Riverside and Menands substations in Albany, N.Y. Using a new 30-meter cable segment fabricated with wire manufactured in Schenectady, SuperPower marked the successful installation and energization of Phase 2 of the HTS Cable Demonstration Project funded by the DOE and the New York State Energy Research and Development Authority (NYSERDA). HTS cables, which carry three to five times more power than the copper-based power cables in use today, can provide an important solution to the ever-increasing demand for more and higher-quality power.

The Albany HTS Cable Project, first installed and energized in July 2006, initially consisted of two sections—a 320-meter-long section connected to another 30 meters long—both fabricated with the so-called first-generation HTS wire. During Phase 2 of this demonstration project, the 30-meter section was removed and replaced during 2007 with an equal section fabricated from SuperPower’s new second-generation (2G) HTS wire.

This is the first in-grid demonstration in the world of a device that incorporates 2G HTS wire, which is expected to provide important performance and price benefits compared with copper wire. HTS cables carry more power more efficiently because they occupy less space than comparably rated conventional cables. HTS cables can be retrofitted into existing underground conduits, eliminating the need for additional trenching, which will be of particular benefit in highly congested urban settings, such as New York City.

The $27 million Albany HTS Cable Project began in 2001 with a $6 million grant from NYSERDA and $13.5 million provided by the DOE. SuperPower; Sumitomo Electric Industries (Osaka, Japan); Linde, formerly known as BOC (Germany); and National Grid (Westborough, Mass.) have all contributed their technical capabilities to this project. SuperPower has managed the project and manufactured the 2G HTS wire; Sumitomo has manufactured and installed the HTS cable systems; and Linde has provided and monitored the cryogenic refrigeration system that is used to cool the HTS cable to –333F.

APS announces world-class-size solar plant. Arizona Public Service Co. (APS) has announced plans for one of the world’s largest solar facilities: a 280-MW concentrating solar power (CSP) plant to be built 70 miles southwest of Phoenix, near Gila Bend, Ariz.

The Solana Generating Station will be built by Abengoa Solar Inc. and is scheduled to provide renewable energy beginning in 2011. It will provide APS with more solar electricity per customer than any utility in the U.S. The facility also would be the largest solar power plant in the world if it were in operation today.

APS noted that it chose Abengoa Solar because of its extensive experience constructing, owning, and operating solar power plants. Abengoa Solar deploys CSP technologies across the world, including large-scale facilities under construction or development in the U.S., Spain, Algeria, and Morocco.

Unlike traditional solar-photovoltaic plants, which use direct sunlight to produce electricity, CSP uses the sun’s heat. Parabolic mirrors track the sun and focus solar energy on a heat transfer fluid. Once heated, the liquid converts water into steam, which turns the plant’s turbines to create electricity. This technology allows the plant to produce more energy for customers than a photovoltaic solar power plant, which only produces electricity when its panels are exposed to direct sunlight. (For more information on concentrating solar technology, see POWER, December 2007, p. 40.)

APS also recently announced that it has joined a multi-state consortium of southwestern utilities that have an interest in contracting for a separate 250-MW solar power plant. Should that project proceed to completion, APS customers will receive a portion of the energy from the joint development project, as well as all of the energy from the Solana facility.

Correction

In the February Speaking of Power column, the title for John Hutton’s position in the British government should have been secretary for business, enterprise, and regulatory reform.