O&M

-

O&M

Steam Turbine Blade Reverse Engineering, Upgrade, and Structural Design

Steam turbine blade cracking often suggests the need for an upgraded blade design. Follow the process of reversing engineering a failed blade to produce a more reliable and efficient design.

-

O&M

How Overcycling Induces Economizer Tube Failures

Why do some HRSG economizers and feedwater preheaters seem to suffer tube failures more frequently than others? If frequent failure is your problem, the cause may not necessarily be your heat exchanger’s design or how often you cycle your plant. Don’t forget to carefully check your feedwater controls—they may be cycling more than your HRSG.

-

O&M

Layup Practices for Fossil Plants

Improper layup practices are a major contributor to boiler tube failures and to steam turbine pitting and cracking in U.S. fossil plants. EPRI’s research into identifying damage mechanisms, utility best practices, and innovative new methods to protect plant equipment during outages will aid plant operators in achieving a successful layup.

-

O&M

Report: Fuel for Power Generation to Lead Energy Growth Through 2040

Fuel for power generation will account for about 55% of demand-related energy growth through 2040, ExxonMobil forecasts in its latest annual energy forecast. Like several other forecasters, the Irving, Texas–based oil and gas company also predicts that natural gas will emerge as the leading source of electricity generation by 2040.

-

O&M

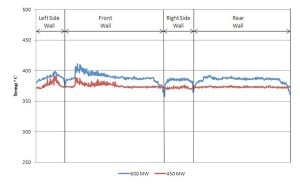

Jinzhushan 3: The World’s First PC-Fired Low Mass Flux Vertical Tube Supercritical Boiler, Part 3

The world’s first supercritical pulverized coal–fired low mass flux vertical tube Benson boiler is Jinzhushan 3, located in the Hunan Province of the People’s Republic of China. The 600-MW Babcock & Wilcox Power Generation Group Inc. once-through boiler burns Chinese anthracite using downshot pulverized coal (PC) technology. Part 1 of this three-part article presented a summary of the project design features. Part 2 discussed the boiler technology. This third and final part reviews the plant’s performance test results.

-

O&M

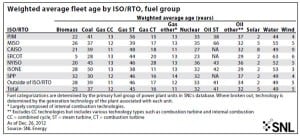

America’s Aging Generation Fleet

Proposed U.S. Environmental Protection Agency rules and a greater reliance on newer generation technologies have put the nation’s aging fossil-fueled generation units at risk of retirement. The numbers demonstrate that the U.S. power generating fleet is older than you may believe.

-

O&M

DHS: USB Drives Spread Malware in Control System Environment at Two Power Plants

A report by the U.S. Department of Homeland Security (DHS) Industrial Control Systems Cyber Emergence Response Team (ICS-CERT) reveals that infected USB drives spread common and sophisticated malware in the control systems at two power plants in separate incidents late last year.

-

O&M

Power Plant Cycling: Growing Regime Needs Better Understanding of Technical and Cost Issues

Increased cycling is now a fact of life for many combined cycle power plants, even those once used for baseload. The shift in regime can have many associated costs, not all of which are obvious.

-

O&M

When Disaster Strikes: Five Lessons for Infrastructure Owners and Operators

Sooner or later, every plant owner will face a natural disaster. Careful planning, preparation, and teamwork are key to getting through in one piece.

-

O&M

Controlling Fugitive Combustible Coal Dust

Regardless of how much prevention is employed to mitigate combustible dust in coal-fired power plants, fugitive coal dust is pervasive and can be dangerous. In coal-fired power plants, mechanical transfer points are leading sources for airborne fugitive dust. However, because coal dust travels quickly over large areas with minimal airflow, fugitive combustible dust settles in many areas.

-

O&M

Emerging Technologies Enable “No Regrets” Energy Strategy

Achieving a balance between affordable and sustainable electricity while improving reliability is a challenge unlike any the electricity sector has faced since its inception. Technology innovations in key areas such as energy efficiency, smart grid, renewable energy resources, hardened transmission systems, and long-term operation of the existing nuclear and fossil fleets are essential to shaping the future of electricity supplies.

-

History

The Russian Power Revolution

Exports of natural resources have given Russia increased global political and economic clout. But domestically, the world’s fourth-largest generator of electricity has had to embark on the most ambitious reforms ever undertaken to modernize dilapidated Soviet-era power infrastructure and incentivize a massive capacity expansion to support a revived economy.

-

O&M

Edison Mission Energy Seeks Bankruptcy Protection, Separation from Edison International

Edison International’s unregulated power generating unit Edison Mission Energy (EME) on Monday filed for bankruptcy protection after reaching a reorganization agreement with its parent company and holders of its $3.7 billion in debt to become an entity that is independent of Edison International.

-

O&M

Users Return to Fogging on Frame 7FAs

It has been a decade since an R0 compressor blade was liberated on one of the eight Frame 9FA combustion turbines at CLP Power Hong Kong’s Black Point Power Station. This catastrophic failure eventually led to GE’s recommendation that operators severely limit or cease using online water wash (OLWW), inlet fogging, wet compression, and evaporative coolers on F-Class turbines.

-

O&M

Duke Prepares for Testing at Edwardsport IGCC Plant

Duke Energy said in mid-October that testing was under way in preparation for commercial operation next year of its 630-MW integrated gasification combined cycle (IGCC) Edwardsport power plant in Knox County, Ind.

-

O&M

EPRI: Generation Sector Research Update

This synopsis of today’s most interesting research related to power generation gives you a glimpse of what’s possibly coming to your plant in the not-so-distance future. Research under way today will surely determine how power plants are designed, operated, and maintained for many years to come.

-

O&M

Insulation and Lagging Fundamentals

Insulation and lagging are key to saving energy in a typical steam plant, and plant operators would be well advised to pay close attention to energy losses in their insulation and lagging systems.

-

O&M

Jinzhushan 3: The World’s First PC-Fired Low Mass Flux Vertical Tube Supercritical Boiler, Part 2

The world’s first supercritical pulverized coal–fired low mass flux vertical tube Benson boiler is Jinzhushan 3, located in Hunan Province of the People’s Republic of China. The 600-MW Babcock & Wilcox Power Generation Group Inc. once-through boiler burns Chinese anthracite using downshot pulverized coal (PC) technology. Part 2 of this three-part article discusses the boiler technology. The third and final part will review the plant’s performance test results.

-

O&M

As Cybersecurity Bill Dies, Newly Declassified Report Underscores Grid Vulnerabilities

Despite growing concern about cybersecurity both in and outside of Washington, the Senate’s cybersecurity bill died a second time on Nov. 13. The apparent inability of Congress to pass legislation designed to protect critical U.S. infrastructure could lead to President Barack Obama implementing some of the bill’s provisions via executive order. A day after the bill failed to gain 60 votes for passage, a recently declassified report was released that finds the U.S. power grid is vulnerable to attacks that could be more destructive than natural disasters such as Hurricane Sandy.

-

O&M

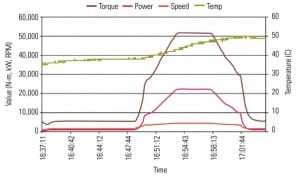

Maximizing Steam Turbine/Compressor Performance with Precise Torque Monitoring at the Coupling

All turbo machinery is subject to degradation that, over time, will affect the system’s efficiency and operational performance. Precise monitoring of turbo machinery performance with continuous torque-monitoring systems can be used to identify gradual efficiency loss. That, in turn, allows a more focused maintenance scope to be developed that can return the system to its optimum operation and efficiency.

-

O&M

Dominion’s North Anna Station Sets New Standard for Earthquake Response

On August 23, 2011, at 1:51 p.m., a magnitude 5.8 earthquake knocked both units at Dominion’s North Anna Power Station off-line—the first time such an event has occurred in the U.S. After 80 days of extensive evaluation and inspection by plant staff and representatives from the U.S. Nuclear Regulatory Commission, both units were back online. What occurred during those days is a remarkable story.

-

O&M

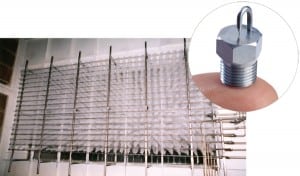

The Evolution of Steam Attemperation

The fundamental design principles and process for modern steam desuperheating, or the attemperation of superheated steam in the power generation industry, have been evolving since the early 1930s. Meeting the requirement for steam quantity, quality, and temperature consistency is the foundation of traditional attemperator component design, particularly for fast-response combined cycle plants.

-

O&M

Major Noise Sources and Mitigation Cost Estimates for Gas-Fired Power Facilities

Natural gas–fired power plants can generate substantial amounts of noise. With proper planning and foresight during the design phase, major noise sources can be effectively mitigated, while failing to plan can be very expensive in the long run.

-

O&M

Upgrading Legacy Gas Turbines’ Fuel Control Systems

Relatively simple upgrades to legacy turbine systems can yield big payoffs in efficiency and reduced maintenance.

-

O&M

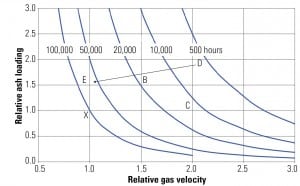

Fly Ash Erosion Control and Prevention

Boiler tube failures (BTFs) are responsible for the largest portion of availability loss (about 4%) in the fossil boiler industry, and approximately 25% of all tube failures are due to fly ash erosion (FAE). An Electric Power Research Institute report indicated that the problem was being managed in U.S. utilities by maintenance activities that were put into effect each time a boiler was taken off-line. The cost of an individual repair was a small fraction of the forced outage cost, and therefore has been considered justified in the past. However, many forced outages continue to be experienced each year due to FAE, and in many cases, these occur at identical locations, indicating that applied solutions relieve, but do not cure, the problem.

-

O&M

Predictive Maintenance That Works

This is the sixth in a series of predictive maintenance (PdM) articles that began in the April 2011 “Focus on O&M” in which the essentials of PdM were introduced. In this occasional segment, we have explored specific PdM techniques, such as motor-current signature analysis, oil analysis and thermographic analysis and their routine use, and ultrasonic and vibration analysis. In this issue we look at lubricating oil wear-particle analysis.

-

O&M

Reducing Ash Agglomeration in JEA’s CFB Boilers

A chronic operational problem with circulating fluidized bed boilers is ash buildup or agglomeration that turns into slag, which forces frequent shutdowns for cleaning. Solving the problem is tricky, because combustion efficiency relies on good fuel quality, but the best fuel for efficiency may not be the best fuel for minimizing furnace and tube fouling and ash plugging.

-

O&M

Unit Cycling Makes the Impossible the Ordinary, EUCG Members Say

Low natural gas prices and still-soft electricity demand are forcing low-load and cycling operations at traditionally baseloaded coal units across the country. The resulting challenges were top of mind at the Electric Utility Cost Group’s (EUCG’s) fall meeting in Denver last week. One member of the EUCG’s fossil generation committee from an Ohio Valley utility said that cycling and low-load operations pose challenges for one of his company’s 1,300-MW coal-fired plants that “two years ago we wouldn’t have considered possible.â€

-

O&M

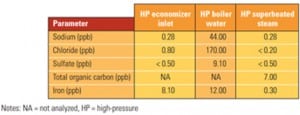

Cycle Chemistry Commissioning Deserves Its Own Strategy

After years of development, design, and construction, your plant is finally nearly ready for startup. But don’t light that cigar yet—at least not until you’ve developed a strategy for commissioning your water cycle chemistry. Root causes of corrosion can be predicted and avoided. The best way to avoid corrosion is to develop and implement plant-specific cycle chemistry commissioning guidelines.

-

O&M

Give Your Plant a Dust Control Tune-Up

Because Powder River Basin (PRB) coal is smaller, more friable, and contains more fine particulates than bituminous coal, controlling the fugitive dust generated as PRB coal moves from bunker to burner tip is problematic. The challenge for material-handling systems at power plants that have switched coals is to minimize this dust and capture it cost-effectively and without compromising safety.