-

O&M

How important is IR detector resolution?

Stretching meager maintenance dollars is a way of life for most maintenance staff. In past years, the cost of an infrared (IR) camera usually came down to a choice between a low-resolution 160 x 120-pixel camera or no camera at all. If the camera was chosen, it usually became clear before long that low resolution […]

-

Legal & Regulatory

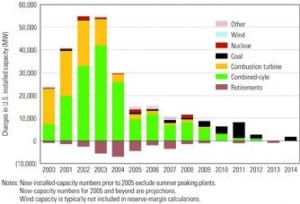

Facilitate plant siting by relaxing ratemaking constraints

The U.S. needs new generating capacity in coming decades to meet growing electricity demand. The increasing scarcity of land within utility load centers, combined with environmental opposition to the siting of plants, often limits siting options to remote locations. Restricting power plants to distant sites necessitates additional transmission facilities, increases delivery costs and electric bills, […]

-

Business

Balancing people, plants, and practices

An essential ingredient in the success of any business endeavor is thorough planning. We’ve all heard the axiom "proper prior planning prevents poor performance" or a variation on that theme. Why the need for peak performance? Competition within the industry has never been as intense, with utilities combining in search of economies of scale. The […]

-

Instrumentation & Controls

Steam turbine upgrading: Low-hanging fruit

In 1500, Leonardo Da Vinci drew sketches of a device that rotated when hot air going up a chimney passed through a set of fan-like blades. Leonardo called his invention a "chimney jack," and although it only turned a roasting skewer, it gave birth to the idea of mounting blades on a shaft to convert […]

-

O&M

Keeping condensers clean

There’s a relatively easy way to make a steam plant more efficient and reliable: keep the tubes of its condenser(s) clean. According to George Saxon, Jr., VP of international sales and marketing for Conco Systems Inc. (Verona, Pa.)—a company whose specialty is cleaning and maintaining condenser tubes—"There are two major problems that result from dirty […]

-

Instrumentation & Controls

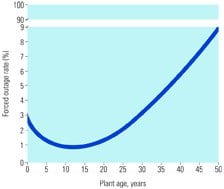

A permanent solution to generator vibration problems

Remember the slogan, "Never trust anyone over thirty?" Chances are you’ve joined the ranks of the over-thirty generation and are dealing with your own personal "maintenance" issues—not unlike the fleet of generators at larger U.S. power plants, whose average age is about 30. Given the continuing growth in U.S. electricity demand and the cost and […]

-

Instrumentation & Controls

Brain surgery breathes new life into aging plants

Age is wreaking havoc on the U.S. generation industry, especially the coal-fired sector. Industry conferences are replete with hand-wringing over the "brain drain," the lack of skilled personnel, the meager number of students pursuing engineering degrees, and the accelerated retirement of the older workers who make up the industry’s experience base. On top of this, […]

-

Instrumentation & Controls

Designing steam cycles to avoid corrosion

U.S. power producers and owners of industrial steam systems each spend about $15.4 billion annually to combat corrosion in their plants. Scale and deposits are thought to be responsible for another $20 billion a year in reduced plant efficiency and lost generation capacity. Corrosion is the primary cause of every other forced outage, and the […]

-

-

Poor priorities

I couldn’t help but marvel at the synchronicity of two unrelated events over the past few weeks. The first, on January 12, was the rare cancellation of a major military acquisition program with problems called "too expensive to fix." It takes an Act of Congress to kill most military contracts due to the pork flowing […]

-

-

Gas

Fleetwide standardization of steam cycle chemistry

Nearly five years ago, a major IPP began standardizing steam cycle chemistry feed, control, and monitoring across its combined-cycle fleet. This article discusses the steps taken, the costs incurred, and the technical and financial benefits achieved. Although the project focused on non-cogeneration plants, the findings detailed below are broadly applicable to other kinds of plants. However, the specific implementations (especially of the chemistry standards) described may have to be modified slightly for application to cogen plants.

-

-

Coal

Gas turbine "refueling" via IGCC

The jury is still out on the economic and technical feasibility of burning gasified coal to generate electricity. Gasification technology has yet to be proven on a utility scale, especially with Powder River Basin coal as the feedstock. And on the generation side, there are more questions than answers about the capital cost and availability of integrated gasification combined-cycle (IGCC) plants. But with natural gas prices high and rising, it’s definitely worth examining whether it would be economically and technically feasible to convert the existing U.S. fleet of gas-fired combined-cycle plants to burn gasified coal.

-

O&M

O&M staff keep their cool at Alaskan plant

Operating a combined-cycle power plant profitably is no walk in the park, even under ideal conditions. But the extreme conditions at the Beluga Power Plant—from isolation to volcanoes—challenge its staff every day in ways that operators in the lower 48 can only imagine.

-

News

Poor Priorities

I couldn’t help but marvel at the synchronicity of two unrelated events over the past few weeks. The first, on January 12, was the rare cancellation of a major military acquisition program with problems called "too expensive to fix." It takes an Act of Congress to kill most military contracts due to the pork flowing […]

-

O&M

Include generators and exciters in your outage inspections

Generators and exciters don’t get much respect during scheduled outages. If yours fall into that category, a strategy that includes regular inspections and routine maintenance is all the more important for identifying incipient problems that could bring a plant down. Read on to learn how to keep your generator or exciter from suffering any of the problems shown in the dramatic photos.

-

News

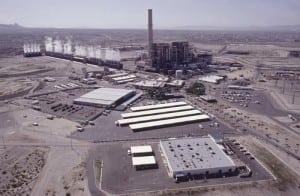

Environmental quandary shuts Mohave plant

Southern California Edison (SCE, Rosemead, Calif.) closed the 1,580-MW coal-fired Mohave Generating Station in Laughlin, Nev., on December 31. In a filing with the California Public Utilities Commission (CPUC), SCE said it expects the plant to remain off-line for four years—the time it will take for the utility and the plant’s other owners to battle […]

-

-

News

Fluor completes Texas project

Fluor Corp. (Aliso Viejo, Calif.) has finished building and commissioning the 620-MW Jack County power plant (Figure 2) near Jacksboro, Texas, for Waco-based Brazos Electric Cooperative Inc. The natural gas–fired, combined-cycle plant officially came on-line on February 1. 2. Texas 2 x 1 step. The gas-fired, 620-MW, combined-cycle Jack County Generation Plant was built and […]

-

-

News

Russia says "da" to floating nukes

The Russian Federation plans to start building a floating nuclear power plant this year. According to the country’s atomic energy agency (Rosatom), the first plant will be small (3 MW) but could lead to the development of offshore plants with capacities of several hundred megawatts. The pioneering plant will be sited off the coast of […]

-

-

News

Pearl Harbor cable links past, future

A new, mile-long submarine transmission cable in Pearl Harbor (Figure 3, p. 10) will facilitate the U.S. Navy’s plan to renovate and expand historic Ford Island. Honolulu-based Hawaiian Electric Co. Inc. (HECO) recently laid two new 46-kV lines beneath the bridge connecting the island to Oahu. The trickiest part of the installation was avoiding the […]

-

-

News

A breakthrough in hydroturbine design

One of the distinguishing characteristics of deregulated power markets is variable demand. The ability to operate efficiently at partial loads can determine whether a plant is profitable or not. This need creates special challenges for hydroelectric turbines, because at partial loads they often exhibit strong swirl in the draft tube at the outlet of the […]

-

-

Legal & Regulatory

Get involved!

The Combined Cycle Users’ Group (CCUG) was formed to address issues of importance to users, particularly the interactions among the major systems of combined-cycle power plants: the steam turbine, combustion turbine(s), and heat-recovery steam generator. The added value of becoming a CCUG member is the opportunity to interact with other operators, as well as designers, […]

-

Legal & Regulatory

Hybrid generation markets endanger competition and innovation

Competition in power generation fosters technical innovation, cleaner power plants, and downward pressure on prices. Before the 1980s, such competition was almost nonexistent: vertically integrated utilities built and operated the vast majority of U.S. plants with oversight by state regulators. The Public Utility Regulatory Policies Act of 1978 and the Energy Policy Act of 1992 […]

-

Gas

Designing HRSGs for cycling

With U.S. combined-cycle plants increasingly being cycled—rather than being run continuously, as they were designed to do—owner/operators worry that units expected to last two or three decades may survive only a few years without an expensive overhaul. Cycling takes as much of a toll on heat-recovery steam generators as it does on gas turbines. Whether you’re procuring a new HRSG or adapting an existing one for cycling service, robust design features should be what you’re looking for.

Search