The POWER Interview: 3D Printing as a Supply Chain Solution

Issues with the global supply chain have impacted the power generation sector, in much the same way those problems have affected other industries. Sourcing of materials, including spare parts for boilers and turbines, solar panels and other solar-related equipment, and items needed for wind power and other renewable energy sources, has delayed projects worldwide. The nuclear power industry also is looking at 3D printing.

Replique, a German-based company, maintains a digital inventory 3D printing platform, part of a newer technology of 3D printing that could shape the future of spare part production.

The use of 3D printing technology to enable the fast availability of spare parts—when needed, where needed, and in the right quantity—is becoming a reality thanks to Replique and others in the 3D printing space. Dr. Max Siebert, CEO and co-founder of Replique, provided POWER with insight into what his company’s model means for original equipment manufacturers (OEMs) and their customers.

Replique’s industrial 3D printing platform includes a global, decentralized, and secured printing network. The company helps customers with design, technology, and material selection, and digital warehousing.

POWER: Can you start by giving our readers a quick overview of who Replique is and what your company does?

Siebert: Sure—Replique is part of BASF’s internal incubator program, Chemovator GmbH, and has enabled the first fully encrypted digital inventory 3D printing/additive manufacturing (AM) platform that offers OEMs a secure and sustainable means of providing spare parts on demand, anytime, anywhere, to their customers.

We achieve this by combining our digital inventory platform (Figure 1) with a global decentralized 3D printing network of AM professionals. Via this combination, we offer OEMs an end-to-end solution from design to manufacturing and part shipment.

POWER: What specific challenges do you address for OEMS?

Siebert: First, an OEM might need to provide critical spare parts with uncertain demand, or support spare parts for aging assets, but would typically find that the supplier or tooling is no longer available. Working with us, the OEM just needs to store the design in our digital inventory. Once a breakdown occurs, we print the spare part locally, on-demand.

Also, be it at the beginning of the product phase or throughout the whole lifetime, the production of small and mid-volume series is connected to high costs and risk. Using AM, we’re enabling OEMs to cost-efficiently produce parts from a batch size of just one, with close to zero fixed costs as there is no tooling or minimum order quantities required.

Additionally, when it comes to the supply chain, via our offering, OEMS can reduce warehousing and transport costs, limit environmental impact and improve resiliency.

POWER: Regarding that last point—given the increasing focus on supply chains and the way in which they continue to be impacted, can you tell us more about how you reduce supply chain costs and improve resiliency?

Siebert: The fact that spare parts are housed digitally (Figure 2) rather than in a physical warehouse, eliminates both storage and transportation costs. Storing parts physically can also require disposal costs, should parts become obsolete, which in turn presents an environmental concern. With our model, once a part is ordered, it is automatically sent to the most appropriate production partner in our AM network. Parts can be produced everywhere and at any time, even at remote locations—reducing CO2 in logistics and improving supply chain resiliency.

Ultimately, supply chains can be hit for a variety of reasons, be it global pandemics, cross border trade issues or by ships getting stuck in the Suez Canal. In each case goods and parts are prevented from getting to where they need to be on time, which can lead to sleepless nights for OEMs. Our solution overcomes such issues by enabling the ability to print whatever the customer needs, whenever it is needed, wherever it is needed, and in the exact quantity needed.

POWER: Couldn’t OEMs just equip themselves with the technology and deploy your model?

Siebert: The reality isn’t that straightforward. 3D printing of spare parts can often come with pitfalls, even to those with manufacturing expertise, which is why many companies—including global automakers and aircraft manufacturers—turn to experts and service bureaus for advice and support in this area. We work closely with our OEM customers to carefully analyze spare part inventories, including technical and economic factors such as material, height, demand frequency and supplier dependency. It might be that not every part is available or even suitable for 3D printing. We can convert 2D drawings into 3D or reverse engineer parts if drawings no longer exist, before helping OEMs select the right technology and material for their spare parts, depending on their requirement (e.g. stiffness, hardness, UV-resistance).

POWER: In which sectors do you see your offering playing a role for OEMs and can you offer a flavor of the customers you are already working with?

Siebert: Right now, we are working with those in a variety of different sectors—including consumer products, energy, automotive/transport, agriculture and construction, and heavy machinery.

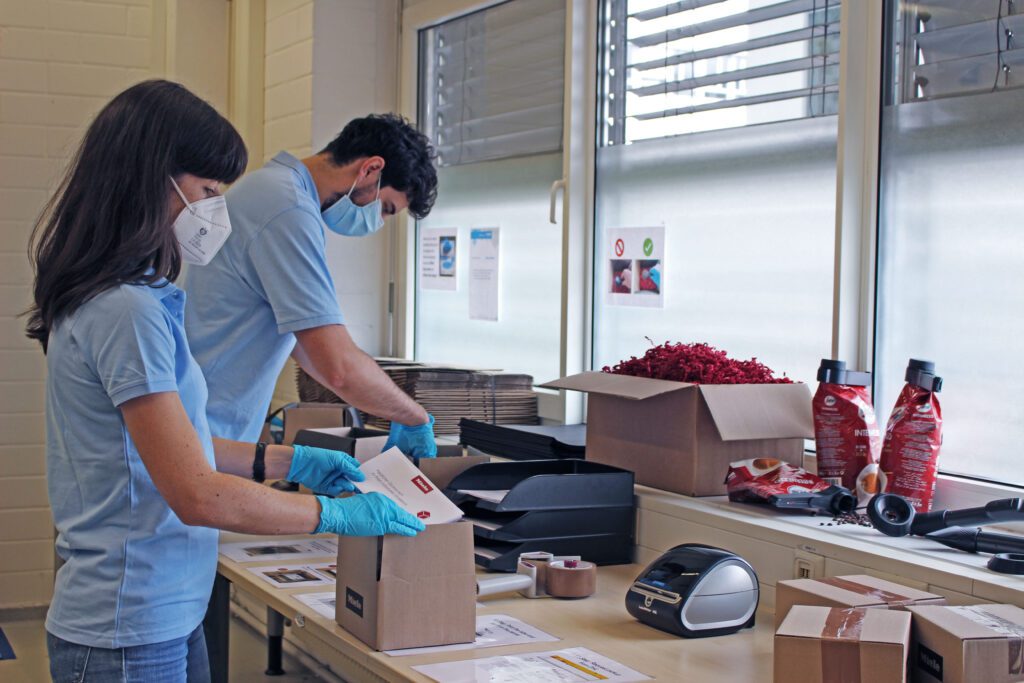

Our customer, German home appliances manufacturer, Miele, is a good example from the consumer goods sector (Figure 3). The company uses our platform to quickly and cost-efficiently provide new accessories to customers. The full integration of our platform into their online shop made the shift to distributed manufacturing possible. Another customer, H. Gautzsch Firmengruppe, uses our platform as part of its sustainability strategy, providing spare parts to customers to prolong product lifecycles. Here our digital inventory plays a crucial role.

Elsewhere, 3D printing is a good fit for industries with long-lasting machinery, where traditional mass production is difficult due to the low part quantities required. This applies to heavy machinery, but is also the case across sectors like transport, agriculture, construction, mining, and oil and gas. Companies in these sectors want to improve the availability of spare parts, while optimizing costs. The costs of spare parts, for example, can increase by up to 20 times after serial production.

POWER: While this appears to be a good solution for many industries, there must be concerns that OEMs sometimes raise—for example security of their intellectual data. How do you ensure a lock-tight process?

Siebert: Security, and quality assurance, are two primary areas that were top of our list right from the get-go. Dealing with each in turn, intellectual property needs to stay in the right hands, which is why we take strong measures to encrypt all data sets on our platform. Moreover, we close non-disclosure agreements with our manufacturing partners to ensure OEMs’ designs are secure and confidential. In terms of quality assurance, we carefully select our production partners to identify and check their capability to ensure repeatable fit-for-purpose parts.

POWER: With 3D printing so fundamental to your offering, where do you think the technology is headed moving forward? Has it fulfilled its expectations, or are there areas in which it still needs to deliver? If so, what are they?

Siebert: 3D printing offers many significant opportunities and is always evolving. First, for several reasons, costs of 3D printing are decreasing. Machines are getting faster, and the benefits of parallelism are used by machine manufacturers, for instance with the use of two extrusion heads instead of one, or 12 lasers instead of four. This reduces printing time incredibly. In addition, support-free printing is now possible, which reduces post-processing time as well as material usage. Lastly, new and more efficient technologies are appearing, such as wire arc, which works by melting metal wire using an electric arc as the heat source, and Palette 3, where multiple materials can be used simultaneously. These technologies not only enable cheaper raw material but are usually also faster.

However, to be able to use 3D printing in new applications and achieve the same possibilities as traditional manufacturing, the range of materials must improve. Even though AM is not suitable for every part in every industry, with current trends, we believe it will be a major enabler of digital supply chains and a complement to traditional manufacturing technologies.

POWER: As a company, you’re still in your initial phase, but what are your objectives insofar as growth and development?

Siebert: Right now, we are moving forward with OEMs that are fairly advanced in their 3D printing journey. But we also want to enable AM for companies who are new in this field and scale up business across the globe. As a digital platform, we expect strong exponential growth, partly because our current customers can extend our services for a wider part range, and partly because new companies will start leveraging our solution.

We know that currently about 6% of all spare parts are 3D printable, and our goal is to supply the highest proportion of that. If companies move to our digital inventory and on-demand 3D printing, a major cost improvement can be achieved and sustainability can increase significantly. But to achieve this, and indeed for AM to fulfil its true potential, a rethinking of current supply chains is needed.

As it stands, 3D printing is to some extent still limited to “yesterday’s” designs. In the future, parts will be constructed for 3D printing, reducing costs, and optimizing the topology and weight of a part. The 3D printing industry still has to show these advantages to the rest of the world, who, to a large extent has yet to properly consider the technology as a viable solution to their design and manufacturing needs.

—Darrell Proctor is a senior associate editor for POWER (@POWERmagazine).