POWER

-

Wind

Greener than thou

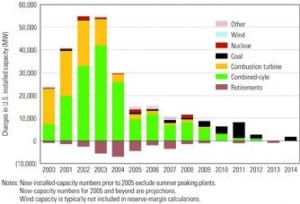

U.S. wind power is on a roll, with wind farms sprouting like weeds. But in the near future, utilities may end up paying higher prices for wind capacity because state regulators are, in effect, imposing an artificial floor on national demand for generation fueled by renewable resources. At last count, at least 20 states had […]

-

Gas

Global Monitor (May 2006)

Nuclear hot streak continues/Who’s winning in U.S. wind power?/ Canadian wind picking up too/ Brazilian port powers itself/ Biomass meets CHP in Sweden/ Power surfing from Scotland to Germany

-

Water

Focus on O&M (May 2006)

Desalination, Italian style; How to minimize DI operating costs; Advanced flow meter works with shorter pipe runs; Why tubing beats piping.

-

Legal & Regulatory

State monitoring fails the cost/benefit test

Steven F. Greenwald and Christopher A. Hilen Utility regulators in California and other states have begun subjecting power plants to extensive oversight of their O&M activities. These oversight programs are a response to allegations that generators purposely shut operational plants down to drive electricity prices up during the 2000–2001 energy crisis. These state initiatives […]

-

Water

Recycling, reuse define future plant designs

The Valley of the Sun went off the water wagon on March 4, ending a record 136 consecutive days without measurable rainfall. That first 0.05-inch sip, followed by a 0.18-inch gulp the next day, only left residents yearning for more. But Mother Nature was only teasing, because the rest of March remained dry. On March […]

-

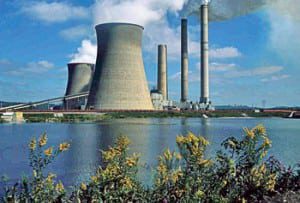

Coal

Preparation keyed Entergy’s responses to Katrina, Rita

With the 2006 hurricane season about to begin, climatologists are predicting that the Atlantic Ocean will spawn 17 “named” storms this summer and fall, with 9 categorized as hurricanes and 5 expected to be “intense.” Whether or not your plant lies in a vulnerable coastal area, you’d do well to learn a few lessons from Entergy’s unique experience last year.

-

Coal

Curbing the blue plume: SO3 formation and mitigation

Understanding why stack emissions become opaque leads to better choices of systems for controlling SO3 and other pollutants, based on current and future plant operating configurations.

-

Coal

How accurate primary airflow measurements improve plant performance

Primary airflow has a major impact on the efficiency, capacity, and cleanliness of pulverized coal–fired generation. Inaccurate measurements that underestimate primary airflow levels can lead to negative operational outcomes that include increased boiler gas temperatures, flyash loss-on-ignition, excessive NOx emissions, and higher-than-necessary fan power consumption. We remind you how to avoid those headaches.

-

Gas

Cheng Cycle flirts with 2 ppm NOx— and CO

Three years ago, an article in POWER described how Cheng Power Systems, by modifying the combustors of several popular gas turbines, had used steam injection to lower the units’ NOx output to about 5 ppm—but some models had substantial CO levels without combustor modifications. Since then, the company has developed new combustor nozzles that recently […]

-

Coal

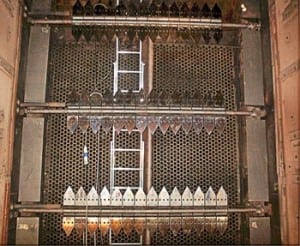

Designing and maintaining steam coil air preheaters for reliability and effectiveness

If engineered well and drained properly, a simple finned-tube heat exchanger can help maximize a fossil-fueled power plant’s combustion efficiency, capacity, and air pollution reduction. Use the guidelines in this article either to return a disabled steam coil air preheater to service or to improve the performance of a unit that may have been wasting […]

-

Instrumentation & Controls

Solving plant vibration problems

Solving insidious vibration problems in rotating equipment may sometimes seem like a black art that requires the right incantation. But identifying the root cause of the vibration is actually a science. By using cutting-edge vibration measurement tools in concert with computer simulations, plant operators can arrive at a permanent, cost-effective solution to virtually any vibration […]

-

Gas

Designing duct burners for variable GT loads

Duct burners use supplementary firing to increase the heat energy of a gas turbine’s exhaust, making it possible to increase the output of a downstream heat-recovery steam generator (HRSG). Early systems of the 1960s took a conventional approach to burner design. The exhaust of the turbine was directed into a windbox and then into a […]

-

Instrumentation & Controls

Brain surgery breathes new life into aging plants

Age is wreaking havoc on the U.S. generation industry, especially the coal-fired sector. Industry conferences are replete with hand-wringing over the "brain drain," the lack of skilled personnel, the meager number of students pursuing engineering degrees, and the accelerated retirement of the older workers who make up the industry’s experience base. On top of this, […]

-

Instrumentation & Controls

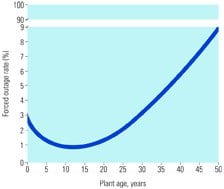

Designing steam cycles to avoid corrosion

U.S. power producers and owners of industrial steam systems each spend about $15.4 billion annually to combat corrosion in their plants. Scale and deposits are thought to be responsible for another $20 billion a year in reduced plant efficiency and lost generation capacity. Corrosion is the primary cause of every other forced outage, and the […]

-

Western coal rush

—Dr. Robert Peltier, PE Editor-in-Chief The hot hand in coal-fired power plant development is undoubtedly held by Nevada. In a departure from Sin City’s latest marketing slogan, "What happens in Vegas, stays in Vegas," most of the 5,500 MW to be generated by plants proposed for the state is destined for use elsewhere, principally […]

-

Instrumentation & Controls

Air heater leakage: Worse than you think

Rotary regenerative air heaters capture and recycle about 60% of the heat energy exiting the boiler—energy that would otherwise go up the stack. For a 500-MW coal-fired plant, the recycled energy amounts to about 1.5 billion Btu per hour, and reusing it reduces fuel consumption by about 1,500 tons per day. Although most performance engineers […]

-

Howdy . . . and welcome!

During the 17 years I’ve lived in Texas, I don’t know that I’ve actually heard anyone say, "Howdy!" but it seemed like the most appropriate word to associate POWER with its new headquarters in Houston. As you may have heard, POWER magazine and related properties were purchased by The TradeFair Group from McGraw-Hill on March […]

-

Coal

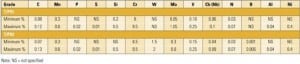

Why new U.S. supercritical units should consider T/P92 piping

T/P92 is being heralded as a superior and lower-cost alternative to T/P91 for new power plants with pressures above 3,600 psi and temperatures above 1,100F—such as the supercritical and ultra-supercritical units proposed to be built in the U.S. over the next few years. The switch from T/P91 to T/P92 would represent the next step in […]

-

Gas

Giant GE GT goes global

In late February, the largest gas turbine ever manufactured by GE Energy at its Belfort plant in France began a 30-day journey by land and sea that will take it to a new power plant in Spain. The Frame 9FB gas turbine—which is also the first built completely in Belfort—was loaded onto a special, wide-load […]

-

Marmaduke

Marmy stops dreaming

Steve Elonka began chronicling the exploits of Marmaduke Surfaceblow—a six-foot-four, steel brush-mustached marine engineer with a foghorn voice—in the pages of POWER in 1948. That was the year that Marmy raised the wooden mast of the SS Asia Sun with the aid of two cobras and a case of Sandpaper Gin. This classic episode, written in the late 1960s, shows that even minor consequences of a steam turbine overhaul can cause problems. And as Marmaduke shows, solving any problem requires equal parts judgment, logic, and experience. Enjoy.

-

Instrumentation & Controls

Siemens units keep pace

Earlier this February, Siemens Power Generation’s (SPG’s) factory in Berlin delivered its 500th gas turbine. The SGT5-4000F (Figure 2), formerly called the V94.3A, is nominally rated at 270 MW and weighs in at about 300 metric tons. With this shipment, the Berlin facility can boast of having built gas turbines with a cumulative capacity of […]

-

Commentary

Economic dispatch done best when done locally

Both the states and the federal government are looking at who should decide which power plants are used at any given moment to meet demand. In question is which approach will reliably serve customers with the lowest-cost electricity. The Energy Policy Act of 2005 (EPAct) raised the issue when it directed the Federal Energy Regulatory […]

-

Nuclear

Monster moisture separators

Thermal Engineering International (TEI) (USA) Inc. (Santa Fe Springs, Calif.)—a subsidiary of Babcock Power Inc. (Danvers, Mass.)—recently shipped two of the largest pressure vessels in the company’s 90-year history. The pair of huge (13-ft-diameter, 110-ft-long) moisture separator reheaters (MSRs) were designed at corporate headquarters and built in TEI’s factory in Sapulpa, Okla. The 300-ton MSRs […]

-

Coal

Big bucks for carbon sequestration

The California Energy Commission (CEC) recently awarded about $14 million for carbon sequestration projects to be overseen by the West Coast Regional Carbon Sequestration Partnership. Westcarb, as the partnership is known, is part of the U.S. DOE’s effort to deploy technologies through its Regional Carbon Sequestration Partnership (RCSP) program. New members Alberta and British Columbia […]

-

O&M

SWAT team helps shorten forced outage

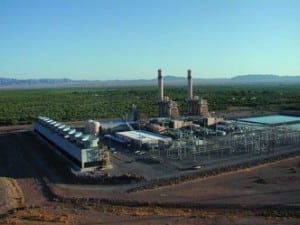

Calpine Corp.’s South Point Energy Center in Mohave County, Ariz. (Figure 1) is a 520-MW natural gas-fired, combined-cycle facility with two Siemens Westinghouse 501FD gas turbines and one steam turbine-generator with a BB33 high-pressure (HP) section, a BB65 intermediate-pressure section (IP), and a 65CC intermediate/low-pressure (LP) section. The plant entered commercial service in June 2001. […]

-

O&M

Wireless vibration monitoring shows benefits

The 1,768-MW Baldwin Energy Complex in Illinois was the site of a joint-venture pilot project to demonstrate a wireless vibration-monitoring system for a coal pulverizer. The partners in the project were EPRI and the plant’s owner, Houston-based Dynegy Midwest Generation. A key objective of the project was to identify a reliable wireless system capable of […]

-

O&M

How important is IR detector resolution?

Stretching meager maintenance dollars is a way of life for most maintenance staff. In past years, the cost of an infrared (IR) camera usually came down to a choice between a low-resolution 160 x 120-pixel camera or no camera at all. If the camera was chosen, it usually became clear before long that low resolution […]

-

Legal & Regulatory

Facilitate plant siting by relaxing ratemaking constraints

The U.S. needs new generating capacity in coming decades to meet growing electricity demand. The increasing scarcity of land within utility load centers, combined with environmental opposition to the siting of plants, often limits siting options to remote locations. Restricting power plants to distant sites necessitates additional transmission facilities, increases delivery costs and electric bills, […]

-

Business

Balancing people, plants, and practices

An essential ingredient in the success of any business endeavor is thorough planning. We’ve all heard the axiom "proper prior planning prevents poor performance" or a variation on that theme. Why the need for peak performance? Competition within the industry has never been as intense, with utilities combining in search of economies of scale. The […]

-

Instrumentation & Controls

Steam turbine upgrading: Low-hanging fruit

In 1500, Leonardo Da Vinci drew sketches of a device that rotated when hot air going up a chimney passed through a set of fan-like blades. Leonardo called his invention a "chimney jack," and although it only turned a roasting skewer, it gave birth to the idea of mounting blades on a shaft to convert […]