Protecting Battery Energy Storage Systems from Fire and Explosion Hazards

There are serious risks associated with lithium-ion battery energy storage systems. Thermal runaway can release toxic and explosive gases, and the problem can spread from one malfunctioning cell to neighboring cells, resulting in catastrophe. Having the right detection and protection systems in place can reduce the risk.

Battery energy storage systems (BESSs) collect and store power generated from facilities, such as solar farms and wind farms, to be used at a later time. While BESSs may be housed in various enclosures, shipping container-type portable units have become the predominant solution for lithium-ion battery storage due to their mobility, modularity, and weather-resistant properties.

They are, in many ways, the perfect solution for energy companies to store energy created by intermittent renewable power sources and to provide stability on the electric grid. However, these BESS shipping containers do pose a significant fire and explosion hazard.

Thermal Runaway

A lithium-ion battery that is malfunctioning or has been damaged in some way will likely experience an internal temperature increase, either gradually or quickly. This temperature increase can cause the release of explosive and toxic gas, and the battery to experience “thermal runaway,” meaning its internal temperature increases at a rate greater than the rate at which the heat can be dissipated into the surrounding environment. This results in a sudden—and often explosive—release of all the thermal and electromechanical energy stored in the cell, and ignition of expelled gas.

|

|

1. Demonstration of a battery rack experiencing thermal runaway. Source: Arizona Public Storage |

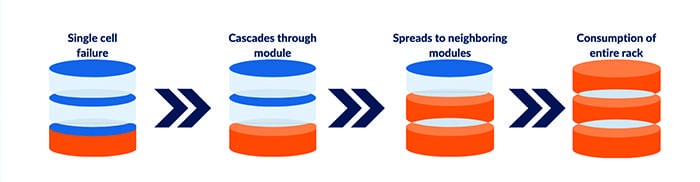

“Thermal runaway is a release of heat within the cell that is so great that it overwhelms the cell and it breaks down,” said Jason Jones, Fike global product manager for Fire Suppression products. “When that happens, you can have a cascading thermal event [Figure 1] where heat from that failure goes to the next cell, which goes into the next cell, and so on.”

A byproduct of a lithium-ion battery experiencing abnormal temperature increase is the release of a mixture of explosive off-gases, including hydrogen. The more batteries that begin to burn, the more dangerous the concentration of off-gases within the enclosure.

Sadly, in April 2019, seven Arizona firefighters were hurt and one was killed from an explosion occurring within a BESS shipping container. When the door to the container was opened by the investigating firefighters, oxygen was introduced into the gaseous mixture. The heat from the malfunctioning batteries ignited the gases and catastrophe occurred.

This is just one example of the danger that exists as a result of ever-increasing methods of energy storage. Fortunately, safety systems are available to ensure an incident such as this never happens again.

Layers of Protection

Nearly all BESSs are equipped with a battery management system (BMS), which ensures batteries operate within safe temperatures. Some of these systems shut off power if elevated temperatures are detected. However, BMSs cannot be relied on as the only form of protection from an explosion or fire because once thermal runaway occurs, it cannot be stopped without fire suppression systems.

“Various layers of protection may be used to protect a battery energy storage system from exploding,” said Carson Stephens, Fike business development manager for Explosion Protection. “A protection method may be recommended based on a number of factors, one of which is proximity to people. For example, an enclosure located near commercial buildings will likely be protected differently from one located in the desert.”

In addition to the BESS’s proximity to urban areas, workers, or other critical assets, other factors that may determine the protection strategy include the concern for preserving the enclosed batteries, the owner’s preference for certain methods (such as using gaseous agent fire suppression instead of water mist), and, of course, available budget. These layers of protection can be thought of as existing on a spectrum, where the earliest protection method detects thermal runaway and removes the hazard, and the latest protection method allows thermal runaway to occur and mitigates the “worst-case scenario” of an explosion. Three protection strategies include deploying explosion protection, suppression systems, and detection systems.

|

|

2. Explosion vent panels are installed on the top of battery energy storage system shipping containers to safely direct an explosion upward, away from people and property. Courtesy: Fike Corp. |

Explosion Protection. To protect against the worst-case scenario of the shipping container exploding, Fike recommends that all BESSs are protected with explosion vent panels (Figure 2).

“If a deflagration occurs within a BESS container, the explosion vents installed on the top of the enclosure will burst at a predefined low burst pressure, releasing the pressure and flames in a controlled way, thereby preventing an uncontrolled rupture of the vessel,” Stephens said. Explosion vents are considered “passive” solutions, meaning they activate from the pressure itself and require no electronic intervention.

Suppression Systems. Fire suppression systems are often recommended to quickly reduce the combustible atmosphere created from thermal runaway. When a malfunctioning battery is detected, either through gas, smoke, or heat detection, the connected fire panel may release one of two recommended fire suppression systems: water mist or gaseous agents.

“Fike recommends water mist as the foundational system to protect a BESS,” Jones said. “Water mist is very effective at absorbing heat, so it’s going to flash to steam and absorb the heat from any fire or heat produced during the thermal runaway process. If you’re using a pumped water mist system, such as Fike’s DuraQuench system, you’ll have a continuous water supply, which provides that continued cooling and inerting effect.” Finally, water mist provides “three-dimensional” coverage, allowing it to permeate the entire space and reach even obscured fires—something a traditional sprinkler system cannot provide.

When there is a need to protect against an incipient Class C fire that may occur even before any battery cells are involved, Fike recommends 3M Novec 1230 or FM-200. These fires may occur within a transformer; inverter; or heating, ventilation, and air conditioning (HVAC) motor.

“Oftentimes, even before the water mist system is activated, we will also use a gaseous agent system to suppress Class C fires that are igniting somewhere outside of the actual battery cells,” Jones said. “That way you get the fast-acting gaseous agent system to potentially put that Class C fire out before it can turn into a Class B fire that involves the battery cells.”

Detection Systems. One of the most impactful decisions for limiting fire damage and preserving the BESS is the chosen method of detection. Various detection options are available to identify the stages leading up to and including thermal runaway: temperature increase, off-gases, smoke, and flame.

The earlier a malfunctioning battery is detected, the sooner fire suppression systems may activate. However, if suppression systems are not installed, detection is still essential as it can activate HVAC vents to flush out off-gases, shut down power, sound alarms, and notify emergency responders. Detection options, from slowest to quickest to activate, include the following:

- ■ Traditional spot smoke detectors and heat detectors are placed inside the BESS enclosure to detect the presence of smoke or heat. However, by the time traditional detection activates, thermal runaway of a lithium-ion battery is well underway. This method is not recommended for those who hope to suppress the fire and preserve the BESS.

- ■ Thermal imaging or flame detectors are commonly mounted outside to monitor multiple BESS units for fire or increased temperatures from the HVAC exhaust vents. Thermal imaging provides added early warning when combined with other detection methods within each BESS unit. Flame detectors will respond to open flame and are required per IFC (International Fire Code) 2021 for rooftop or garage installations.

- ■ Honeywell Analytics industrial gas detection detects presence of off-gas within a BESS unit once it reaches a certain threshold.

- ■ VESDA with integrated gas and smoke detection continuously samples the air for presence of gas or smoke particles within a BESS unit.

- ■ Li-ion Tamer is specifically engineered and designed for BESS fire protection. It provides localized gas detection and reporting within individual lithium-ion battery racks.

Each of these detection methods may be ideal for certain scenarios. It’s the responsibility of the safety solutions provider to communicate the pros and cons of each for the unique application.

BESSs in Buildings

While much of the industry has been focused on portable BESSs contained in shipping containers, various other methods of energy storage also require protection, such as those found within buildings. The aforementioned temperature increases can be monitored and detected, even before off-gassing or thermal runaway occur. Because these battery installations are often located within manufacturing plants, commercial buildings, or residential areas, early identification of potential battery failure is essential.

For example, thermal monitoring displays real-time temperatures of each battery rack. Battery rack ambient temperature is normally about 130F. If it reaches 140F, the battery rack can be removed, cooled, and repaired before off-gassing occurs.

Two types of thermal monitoring systems are available: thermal monitoring cameras and distributed fiberoptic thermal monitoring cables. Thermal imaging cameras may be used to monitor multiple racks of batteries, monitoring for not only overheated batteries, but also for hot spots on metal or exhaust, which may indicate the presence of abnormal temperature increase prior to off-gas or thermal runaway. Fiberoptic distributed temperature sensing cables may be routed throughout battery energy storage racks. They can provide real-time temperature indication and alarm on a battery or rack basis to pinpoint the exact location of an overheated battery. Software is available with a virtual display of the racks including actual temperatures and indicated alarm areas, plus dry contact relay or modbus outputs can be utilized for equipment control.

Valuable Equipment Deserves First-Rate Protection

Reliably protecting a battery energy storage system requires a partner whom you can trust. Multiple variables should be considered, such as whether the BESS is located in a rural or urban area, whether it’s contained within a shipping container or a building, and whether the stakeholders want to protect the batteries themselves or just protect against the worst-case scenario. Because explosion protection, fire detection, and fire suppression are all important considerations for mitigating the effects of thermal runaway within a BESS, it’s recommended to find a partner who can provide reliable solutions to fulfill each of these safety requirements. ■

—Jim Vingerhoets is global product manager for Explosion Protection, and Kevin Montgomery is global product manager for Fire Detection and Control Products, both with Fike Corp.