How & Why to Prevent Cavitation in Piping Systems

Cavitation is a hot topic for engineers, maintenance professionals, and anyone who works with pumping systems—and for good reason. This condition has complicated and difficult-to-identify causes, and its effects can be devastating to equipment, system integrity and overall operations.

Preventing cavitation is a full-team effort when it comes to systems operated with centrifugal pumps. It starts with system design and calculations around net positive suction head (NPSH) before the system is even built. Pump selection, fluid temperature, and inclusion of safeguarding components are all factors that can protect against cavitation in a system.

What Is Cavitation?

From the perspective of an outside observer, cavitation can often be detected just by listening to a system. It can sound almost like the liquid in a system is boiling. The quick, repetitive sounds of bubbles popping is a sure sign that something is not right with your piping system. Some listeners have described cavitation as sounding like coffee beans or gravel in the system.

But what’s actually happening inside the system to cause that noise? Cavitation is the rapid formation and implosion of vapor pockets inside a pumped fluid. The implosions create shock waves that travel through the fluid and damage equipment.

The cavitation process can wreak havoc on sensitive and highly engineered components of piping systems. Pump impellers, casing, piping, and other equipment can experience pitting, erosion, or other damage that keeps these components from functioning correctly. This damage can also shorten the life span of individual system components and of the system as a whole.

Cavitation is much more likely in some systems than others. Systems that are pumping liquids, rather than slurries, are at a higher risk for cavitation. Thinner system fluids, such as water, also make systems more likely to face cavitation. Applications with fluids that are pumped at higher temperatures also need to take more steps to avoid cavitation.

Understanding Cavitation

To understand cavitation, the easiest place to start is one of the most basic cooking concepts: boiling water. When we boil water in the kitchen, it’s all about heat. Water must be heated to 212 F (100 C) to boil.

But heating to that precise temperature is not the only way to cause the rapid vaporization we call boiling. While 212 F is the commonly used boiling point in cooking, scientifically a boiling point is the temperature at which the vapor pressure of a liquid is equal to the pressure surrounding the liquid.

Whether a home cook or a professional chef is at the stove, it is unlikely that the vapor pressure of a liquid will be manipulated in a kitchen environment. That’s why the 212 F metric is used relatively universally (although kitchens at very high elevations are affected by changing water pressure and might use different boiling points).

In industrial systems, fluid pressure is changing throughout the stages of the pumping process. Most commonly, fluid experiences large pressure changes while inside the pump. When fluid is drawn in, it’s quickly pressurized, then experiences a major drop in pressure as it exits the impeller and travels to the pump outlet. This rapidly changing pressure can affect the boiling point of the fluid and create an ideal environment for cavitation to occur.

One important nuance of cavitation is the fact that the vapor pockets actually implode during the process. These implosions send out strong shock waves through the pumped fluid that can cause damage to system components. These shock waves can erode or cause cratering in pump impellers or pump casings, but also in piping or any other part of the system.

While the outlet section of a pump is the most common place for cavitation to occur, it is technically possible in any part of a system with a major pressure drop. Since systems often have many areas of very rapid fluid movement, cavitation can be a concern in multiple parts of the system.

The Dangers of Cavitation

Of course, system operators want to protect the investment they’ve made in their equipment. Pumps and other highly engineered or bespoke components have strict maintenance and repair schedules to keep them performing in top shape. The last thing operators want is to have the system operate in a condition that actively damages equipment.

Cavitation can cause pitting or removal of material in pump impellers or casings. The change in the component’s surface causes suboptimal performance of the entire system. The impeller or casing will have to be replaced much more quickly than expected by its schedule.

Another danger of this type of damage is the material removal from the pump component means that material can enter the pumped fluid. Depending on the system, it could be detrimental to the product to have even tiny amounts of a pump’s material of construction in the fluid.

How to Avoid Cavitation

Preventing cavitation starts in the planning phases of a system. NPSH calculations can help make sure a system never has the opportunity to experience cavitation. Pumps all have a set amount of NPSH required (NPSHr), so the system must always have a level of NPSH available (NPSHa) that exceeds the NPSHr. Pump manufacturers provide the NPSHr for every pump, so system designers can factor it in during the equipment selection process.

Systems can also be designed with temperature control in mind. The cooler a fluid, the less likely it is to reach its boiling point—even if that boiling point is made lower by changes in pressure. Pumping cooler fluids can help prevent cavitation issues in a system.

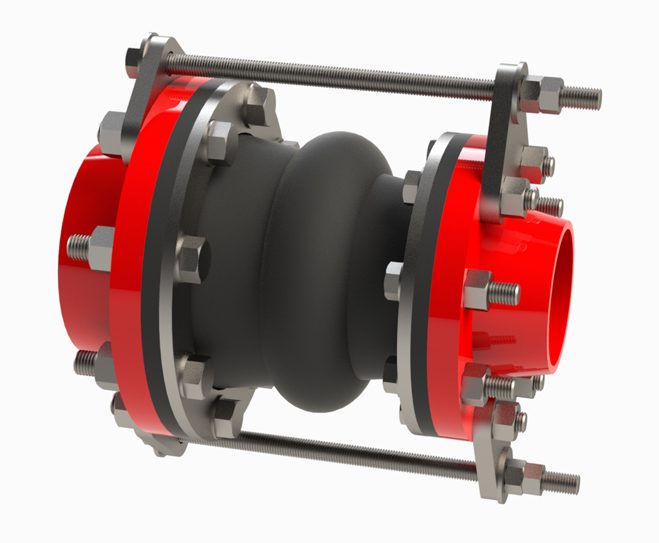

Style RC-231

Certain types of equipment can also help a system avoid cavitation and other undesirable conditions. Even the most carefully designed systems might encounter unexpected issues in real-world operations. When things don’t go as planned, maintenance professionals and engineers need options to be able to avoid some of the major damage that cavitation can cause.

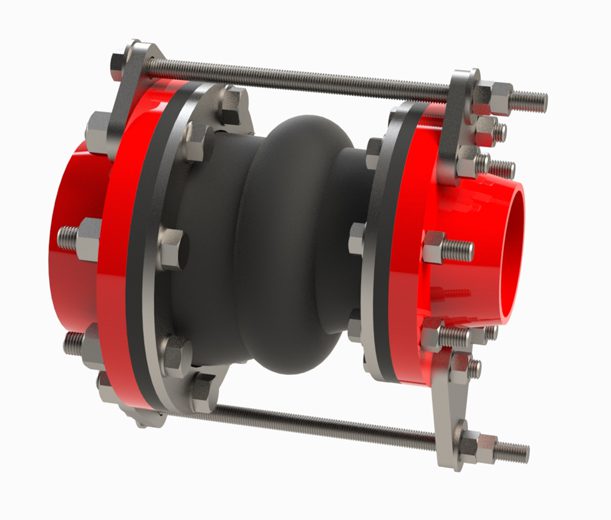

Expansion joints offer system operators the ability to account for real-world issues that are common in piping systems. Proco Products offers Style RC-231 and RE-231 rubber expansion joints as a solution for system operators. These expansion joints are available in different configurations and materials to meet the needs of many different systems. For chemical applications, a variety of elastomers are available to work seamlessly in harsh conditions.

Style RE-231

Some of the benefits of expansion joints include:

- Absorbing directional movement

- Reducing turbulence or material entrapment

- Absorbing vibration, noise and shock

- Compensating for misalignment

Keeping a system running smoothly is a priority for engineers and maintenance professionals alike, and Proco Products expansion joints can help promote optimal operations.

The RC and RE series are both single wide-arch rubber expansion joints. The RC series features concentric designs while the RE series offers eccentric designs. Both series of reducers are available in a range of sizes to accommodate most applications. Contact a Proco Products professional to find the ideal rubber expansion joint for your system.