New-Generation Gas Turbines Steam Ahead

This September, as Siemens Energy wrapped up testing of its H-class SGT5-8000H gas turbine at E.ON’s Irsching 4 gas power plant in Bavaria, Germany, the company raved about what it is calling "the world’s most powerful gas turbine." After firing the prototype megaturbine for 1,500 hours — 1,200 hours of which had been full-load testing — the company said that the 50-hertz machine exceeded the original rated output of 340 MW. Analysis of measurement data now shows that rated output could be increased to 375 MW in simple-cycle duty, it said.

The validation program, which began in April 2008, will now extend the simple-cycle test plant to a high-efficiency combined-cycle plant, beginning phase two of the program. Transfer to the plant operator, E.ON, is expected in 2011. The company suggests that the turbine, based on a combined Siemens and Westinghouse design, will outperform initial projections for output in its combined-cycle mode by 40 MW — bringing it to 570 MW. Expectations regarding the turbine’s efficiency remain at 60%, though this still beats another Siemens design by two percentage points and makes it the "world’s most efficient combined-cycle plant," according to the company.

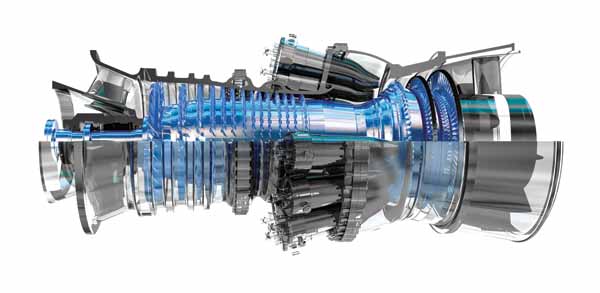

The 440 – metric ton turbine features roughly 1,000 turbine blades (each generates 10 times as much power as a Porsche 911, Siemens boasts). A ceramic coating as insulation and other adhesive coatings make the blades on the front rings impervious to combustion temperatures of up to 1,500C. These special coatings give the turbine a total service life of 25,000 hours — six times longer than pure metal would survive if exposed to the flow of the hot combustion gases. Steel makes up 95% of the gas turbine. In all, it comprises 7,000 components (Figure 2). The turbine features "numerous innovations, including a fully redesigned housing for the combustion chamber."

2. Bright and burly. Siemens Energy has wrapped first-phase testing of its H-class SGT5-8000H gas turbine at E.ON’s Irsching 4 gas power plant in Bavaria. Results suggest that rated output for the 50-hertz turbine has increased to 375 MW from 340 MW in simple-cycle duty. Courtesy: Siemens

The SGT5-8000H is the latest in a new generation of gas turbines — but it isn’t the only one that will be contending for global sales come 2011. Japan’s Mitsubishi Heavy Industries earlier this year completed development of its "J"-series gas turbine, planning to take it to market by 2011. Designed to operate at blistering temperatures of up to 1,600C at the turbine inlet, the 60-hertz machine is expected to achieve a rated power output of about 320 MW (ISO basis) and 460 MW combined-cycle power generation.

In October, meanwhile, GE Energy said it is looking to wheel out an upgraded version of its Frame 7FA gas turbine (Figure 3) by 2012 to help power plant operators use less fuel to generate power. The newly announced version is the turbine’s sixth upgrade. Compared to the original 7FA, which went into service in 1990, this version features an improvement of more than 60 MW. GE told POWER that the new model also has a 35.8-MW and 1.4 percentage points improvement in efficiency over its most widely used 7FA model.

3. Stepping on the gas. GE Energy recently introduced an upgraded version of its 7FA gas turbine. GE claims that a typical power plant operating two new 7FA gas turbines with a single steam turbine in combined-cycle configuration would achieve a fuel cost savings of more than $2.1 million per year at a natural gas price of $6 per mmBtu when compared to a similar plant with an earlier version of the 7FA. Courtesy: GE Energy

The turbine is reportedly being evaluated by several companies. Some of the first new 7FA turbines are planned to be used at the proposed 586-MW Oakley Generating Station in Oakley, Calif. The plant, developed by Radback Energy, is expected to be transferred to Pacific Gas and Electric Co. after it enters operation.