EGS, AGS, and Supercritical Geothermal Systems: What’s the Difference?

The spectrum of geothermal technologies is quickly evolving. This supplement to POWER’s April 2023 feature, “Startups Are Shaking Up Geothermal Power’s Potential,” briefly explains the differences between some engineered geothermal systems.

Conventional geothermal energy is largely produced by hydrothermal systems, which consist of hot water circulated in deep-seated permeable rocks. Resource temperature ranges from high (greater than 150C), medium (90–150C), and low (less than 90C). Geothermal power production typically relies on high and medium geothermal resources with minimum temperatures of about 150C to 180C. Other applications—heating and cooling, industrial processes, and agri-food applications—typically harness medium-temperature resources. At the same time,e geothermal heat pumps (GHPs) widely use low-temperature conditions in the shallow sub-surface to provide efficient space heating and cooling.

However, new technologies promise to open up geothermal energy production from resources seated deeper underground, allowing geothermal energy to be tapped virtually anywhere.

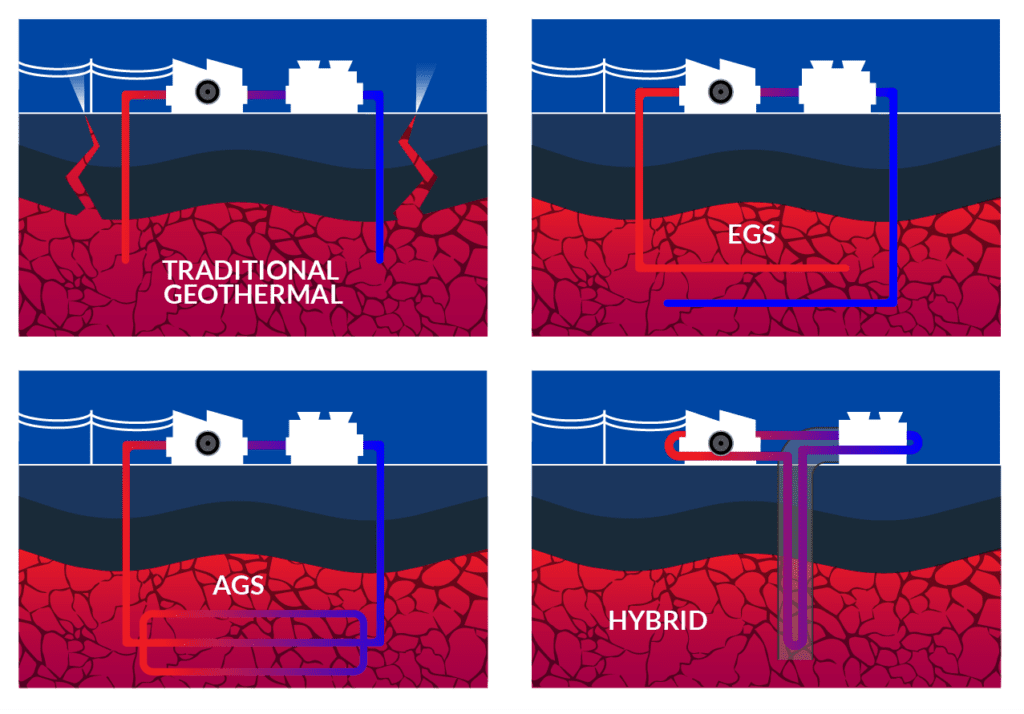

Enhanced (or Engineered) Geothermal Systems (EGS)

EGS “improve[s] the permeability of geothermal systems through hydraulic, chemical, and thermal stimulation,” explains the International Renewable Energy Agency (IRENA) in a February 2023 geothermal technology assessment. “This stimulation can be done in some geological settings that have high sub-surface temperatures but where fluid volumes and/or rock permeability are not sufficient to permit economic extraction using current techniques.” Permeability can be enhanced by stimulating the reservoir by pumping fluids (like water or carbon dioxide) to fracture the rock and create an artificial reservoir, it notes.

EGS has been explored since the 1970s, but efforts to develop EGS have remained small in scale, mainly owing to insufficient reservoir volume, difficulty with drilling, and induced seismicity. Since the first EGS pilot installation at Fenton Hill in the U.S. (and ran from 1974 to 1995), experimental projects have operated at Rosemanowes in the UK; Basel in Switzerland (which, at 3 MW, has so far been the largest in the world); Pohang in South Korea; Hijiori and Ogachi in Japan; and the Habanero project in Australia. Only a few EGS projects are currently operating: the 1.7-MW Soultz-sous Forêts in France; a 1-MW installation in Groß Schönebeck in Germany, and the 27.5-MWth Rittershoffen Geothermal Heat plant in the French Upper Rhine Graben.

Notable new near-term prospects include projects by Fervo Energy. The 2017–established company is exploring a three-pronged approach to revitalize geothermal production with horizontal drilling, multi-zone completion, and distributed fiber optic sensing. “We have drilled the first two horizontal geothermal wells in history at our commercial pilot in Winnemucca, Nevada,” the company said in February. “The clean energy generated from this drilling will help power Google’s data centers in Nevada.”

As of February 2023, Fervo had signed 93 MW of power purchase agreements to develop a next-generation geothermal power plant, and it is targeting operating more than 1 GW of geothermal projects by 2030. These projects could “direct 24/7 carbon-free electricity not only to utilities but to behind-the-meter partners including direct air capture, hydrogen production, and other energy-intensive industries,” it says.

Advanced Geothermal Systems (AGS)

Advanced Geothermal Systems (AGSs) are “deep, large, artificial closed-loop circuits in which a working fluid is circulated and heated by sub-surface rocks through conductive heat transfer,” IRENA notes. In essence, these systems are deep closed-loop heat exchangers.

According to the U.S. National Renewable Energy Laboratory (NREL), several AGS designs have been proposed “based on different geometries, heat transfer fluids, and physics principles.” The national lab suggests that AGS may be attractive because it may facilitate heat production estimates “with relatively high confidence.” At the same time, “reservoir stimulation is not required, which limits the risk of induced seismicity and lowers water consumption.” As prominently, it can “theoretically be applied anywhere.”

However, AGS requires “substantially longer well bores” to increase the surface area for heat transfer, which may result in higher drilling costs, IRENA notes. NREL highlights similar challenges, including “potentially complex downhole completions and creating sufficient area for heat transfer with the surrounding rock.” The commercial viability of AGS, meanwhile, may depend on declines in drilling costs.IRENA suggests that working fluid advancements, including carbon dioxide, ammonia, and others, could eliminate heat transfer to a secondary cycle and ultimately result in higher power outputs.

For now, closed-loop technology is still under development. A 2019-built Eavor demonstration facility in Alberta, Canada, has shown the technology’s technical feasibility. Eavor is now also building its first 8.2-MWe commercial implementation of an Eavor-Loop in Bavaria south of Munich near Geretsried, Germany. Construction began in October 2022, and drilling is scheduled to commence in July 2023.

Along with Eavor, companies exploring AGS systems include GreenFire Energy’s “GreenLoop.” The California-based firm is slated to provide the AGS technology as part of the Wells2Watts consortium at Baker Hughes’ Energy Innovation Center in Oklahoma City, Oklahoma. “Previously, the technology was used in the first field-scale demonstration of closed-loop technology at the Coso geothermal field in Coso, California,” GreenFire noted. The Wells2Watt project will “create the first of its kind closed-loop geothermal laboratory in the world,” it said.

Hybrid Geothermal Systems

Some startups are considering hybrid systems that combine both EGS and AGS. Houston-based Sage Geosystems envisions a closed-loop vertical geothermal single-well design, which could be used to “recomplete underperforming hydrothermal wells and depleted deep natural gas wells,” the company said. “Cooled fluid is pumped from the surface down the outer ring of a double-walled tube. Heated fluid returns to the surface via the inner tube. This results in no discharge to the air of hydrogen sulfide or steam during operation and no fluid exchange or loss with the subsurface.”

The concept targets a temperature range between 100C and 250C at septs of 3 to 6 kilometers. Sage also plans to deploy a geothermal modeling tool, GeoTwin, and a downward-oriented fracturing technology called HeatRoot. Finally, it plans a demonstration of a supercritical carbon dioxide turbine, which could double the efficiency of converting heat to power. Sage is notably also exploring integrating concentrated solar power (CSP) with pressure storage, a form of long-duration energy storage deep in the earth. The company also has a joint venture agreement with German firm ZeroGeo Energy to develop long-duration energy storage and baseload geothermal power generation that leverages hot dry rock technologies.

Supercritical Geothermal Systems

Supercritical geothermal systems are largely characterized by very high temperatures and a natural reservoir containing fluid in a supercritical state (for example, water at temperatures of at least 374C and pressure of at least 221 bar).

The Clean Air Task Force (CATF), a “non-ideological” advocacy group that is working to advance geothermal potential, refers to these systems (and others that circulate water through rocks that are above 400C) as “superhot rock” systems.

“Accessing affordable superhot resources could transform the power industry but will require innovations in drilling and reservoir engineering,” CATF noted in a November 2022 report. “The injected water transforms into a superhot, superfluid form scientists call ‘supercritical’ water,” it explains. “Supercritical water can penetrate fractures faster and more easily and can speed far more energy per well to the surface—roughly five to ten times the energy produced by today’s commercial geothermal wells or predicted for lower-temperature engineered wells. This means that a few superhot rock wells can bring substantial commercial energy to the surface.”

According to IRENA, such systems would be suited to volcanic hydrothermal resources in Iceland, Japan, Kenya, Mexico, and New Zealand. Several research projects are assessing system potential, including the Iceland Deep Drilling Project, the DESCRAMBLE project in Italy, and the Geothermal: Next Generation initiative in New Zealand.

IRENA suggests, however, that supercritical geothermal systems face myriad technical challenges. “Very high enthalpy fluids are often very corrosive. Most supercritical temperature wells have encountered challenges regarding low permeability, drilling, and well completion,” it says.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).