Plant Design

-

O&M

Lignite Drying: New Coal-Drying Technology Promises Higher Efficiency Plus Lower Costs and Emissions

The U.S. Department of Energy (DOE) and Great River Energy are testing a new coal-drying technology that could dramatically reduce the emissions of lignite-burning power plants. The project was selected for funding during Round I of the DOE’s Clean Coal Power Initiative (CCPI), a series of competitions to demonstrate a range of promising clean-coal technologies. […]

-

Coal

Speaking of Coal Power: IGCC Sticker Shock

Former Illinois Senator Everett Dirksen once observed, "A billion here and a billion there, and pretty soon you’re talking real money." The same can be said about skyrocketing estimated costs of integrated gasification combined-cycle (IGCC) plants as their designs are fleshed out. The higher price tags shouldn’t be a surprise — the more you learn […]

-

O&M

PRB Tech Notes: Lawrence Energy Center Showcases Winning Plant

Lawrence Energy Center (LEC) proudly hosted about 60 representatives of the Powder River Basin Coal Users’ Group (PRBCUG) at its July 24th open house, luncheon, and plant tour. LEC was named the PRBCUG’s 2007 Plant of the Year at this year’s ELECTRIC POWER Conference and Exhibition in Chicago, May 1 – 3. Traditionally, the winning […]

-

O&M

Coal Plant O&M: Smart Sootblower Tailors Cleaning to Need for It / Blending’s Impact on Coal Quality

The 1990 amendments to the Clean Air Act require coal-fired power plants to reduce their emissions of the pollutant SO2. To do so, many have switched to, or are considering switching to, Powder River Basin (PRB) coal. Unfortunately, PRB coal has a tendency to leave excessive and tenacious deposits on boiler heat-exchange surfaces. Complicating the problem, the distribution of the deposits is far from uniform.

-

Coal

The Coal Patrol: Coal-to-Liquids Resurfaces after 20 Years

It’s déjà synfuels all over again. With crude oil prices seemingly interminably pegged at over $60 a barrel, the old, beguiling notion of turning coal into liquid fuel — a task accomplished by the Nazis in the 1940s and the South Africans in the 1970s and 1980s — is once again front-page political news in […]

-

Coal

PRB Tech Notes: Pay Me Now or Pay Me Later

Money is always spent with the best intentions. We look for the best deal, often identifying it by the lowest price. Sometimes, our choice works out and we save money and get a great product. When it doesn’t work out, however, we find ourselves spending more and more money to repair or replace our "great […]

-

O&M

Coal Plant O&M: River Locks and Barges Are an Aging Workforce, Too

During 2005, about 150 million tons of coal were transported to power plants by hopper barges plying U.S. inland waterways. With coal-fired plants expected to continue producing 50% of America’s electricity, coal barge traffic is not likely to fall off. In fact, it may increase, for two reasons. One is cost. Shipping coal by barge […]

-

O&M

Pollution Control: LCRA Fayette Lowers NOx Below 0.10 lb/mmBtu

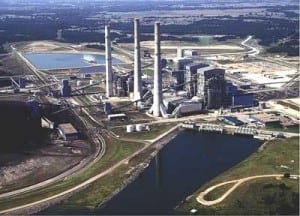

The Fayette Power Project (FPP, aka the Sam K. Seymour Power Station) is a three-unit, coal-fired generating plant sited near La Grange, Texas (Figure 1). Units 1 and 2, each with a nominal rating of 600 MW, are co-owned by the Lower Colorado River Authority (LCRA) and Austin Energy (AE). LCRA is a conservation and […]

-

O&M

Pollution Control: Low-NOx Combustion Retrofit Options

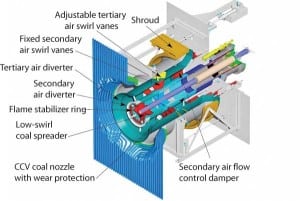

Reducing NOx emissions from large utility coal-fired boilers has been a primary focus of the U.S. power generation industry since passage of the 1970 Clean Air Act and subsequent legislation. By the early 1990s, nearly all such boilers had installed some form of low-NOx burner (LNB) technology and/or overfire air (OFA) — the least expensive […]

-

O&M

Speaking of Coal Power: Coal in a Carbon-Constrained World

Carbon capture and sequestration (CCS) have elbowed their way into the nation’s lexicon with the rise in concern over climate change. But few of the journalists who are hyping global warming have taken the trouble to learn the ins and outs of producing affordable electricity from coal. Citizens of the industrialized world now wring their […]

-

Coal

The Coal Patrol: Glaciers and New Coal Plants

The big buzz still echoing through world of coal-fired generation is the move by two big-bucks private equity investors to take TXU Corp. off the public market, including scuttling announced plans for eight new pulverized coal – fired plants. That leaves alive plans for three new units at TXU’s existing Sandow and Oak Grove sites. […]

-

Coal

PRB Tech Notes: New Plant/Old Plant: Are We Applying What We’ve Learned?

In the last issue of COAL POWER, I urged readers to give coal handling the priority it deserves. The coal yard warrants as much attention as boilers and combustion systems, turbine-generators and auxiliaries, and postcombustion emissions control — the other three "zones" within the plant perimeter — because it is an equally valuable business unit. […]

-

Coal

SO3 Control: AEP Pioneers and Refines Trona Injection Process for SO3 Mitigation

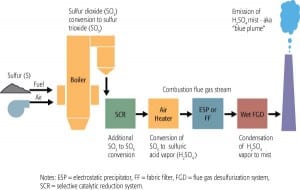

Using a selective catalytic reduction (SCR) system to reduce the emissions of nitrogen oxides (NOx) from a coal-fired power plant is rapidly becoming the norm, rather than the exception. But for many plants, adding an SCR system has unintended consequences: greater oxidation of sulfur dioxide (SO2) to sulfur trioxide (SO3), and a rise in stack […]

-

O&M

SO3 Control: Dominion Demonstrates CleanStack Technology

Dominion Generation (DG) has installed selective catalytic reduction (SCR) systems on many of the large coal-fired generating units it operates. The catalyst used has an SO2 to SO3 oxidation rate of about 1%, which roughly doubles the SO3 concentration at the outlet of the boiler economizers. The magnitude of the increase was proportional to the […]

-

O&M

SO3 Control: How Many Coal Plants Might Have Opacity Issues Due to SO3 Emissions?

Flyash and condensed sulfur trioxide (SO3) are the major components of flue gas that contribute to the opacity of a coal plant’s stack emissions (stack opacity). Estimates are that 75% to 85% of bituminous coal-fired plants with selective catalytic reduction (SCR) and/or wet flue gas desulfurization (FGD) systems are likely to produce enough SO3 vapor […]

-

Coal

Emissions Control: User-Designed Large-Particle Ash Screens Minimize SCR Fouling

Large-particle ash (LPA), also called popcorn ash (Figure 1), is a serious concern for many coal-fired utility boiler operators who have retrofitted their unit(s) with a high-dust selective catalytic reduction (SCR) system. LPA formed in the boiler can easily carry over into the SCR reactor (Figure 2), where it often causes catalyst erosion damage and […]

-

Coal

PRB Tech Notes: Give Coal Handling the Priority It Deserves

Over the past 17 years — dating back to the 1990 Clean Air Act Amendments and including the introduction of retail competition — coal-fired power plants have become much cleaner and more efficient. Utilities have spent many billions of dollars to install pollution controls for regulatory reasons, and only slightly less to upgrade turbine-generators and […]

-

Coal

Coal Plant O&M: Coal Drying Reduces Pulverizer Start-up Costs

If coal leaving a pulverizer isn’t dry, it may plug up the coal pipes leading to the boiler. The coal-drying process in a pulverizer is similar to that used by flash dryers. Certain coals should be preheated to make them more combustible. Generally, preheating is done on higher rank coals — those with a low […]

-

O&M

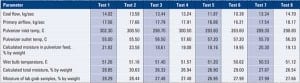

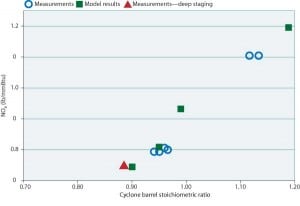

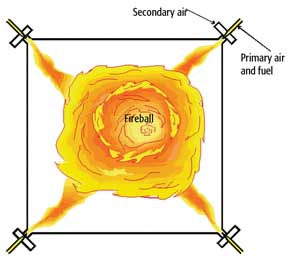

Emissions Control: Layered NOx Reduction on a 500-MW Cyclone-Fired Boiler

Historically, cyclone-fired boilers have been characterized as big emitters of NOx due to the very high temperatures in their primary combustion zone. Uncontrolled levels from 0.8 to 1.9 lb/mmBtu have been typical. The design of cyclone-fired units makes them impossible to retrofit with standard low-NOx burners. Prior to 1997, the conventional wisdom was that cyclone […]

-

O&M

Emissions Control: Cost-Effective Layered Technology for Ultra-Low NOx Control

Layering NOx control technologies can reduce a coal-fired unit’s NOx emissions to levels achievable by selective catalytic reduction alone. Advanced Combustion Technology Inc. (ACT) (www.advancedcombustion.net) has demonstrated that using several in combination can cut emissions from boilers firing eastern bituminous coal or No. 6 oil to less than 0.15 lb/mmBtu. The following two case studies […]

-

O&M

Case Histories: Asheville Power Station’s Retrofit First to Meet North Carolina’s Clean Smokestacks Act

Asheville Power Station’s Unit 1 in Arden, North Carolina, was the first coal-fired unit to be modified with a flue gas desulphurization (FGD) system and placed in service to meet the clean air requirements of the state’s Clean Smokestacks Act. As of November 16, 2005, at least 97% of the sulfur dioxide that had been […]

-

Coal

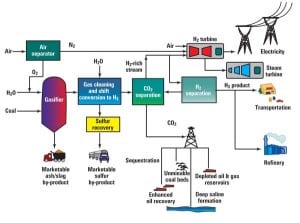

Coal Users Community: Growth Is the Byword for Gasification

The Gasification Technologies Council (GTC, www.gasification.org) was created in 1995 with a straightforward mission: to promote the greater use of gasification as an environmentally and economically preferred alternative for the production of power, fuels, and chemicals from low-value energy sources. Those energy sources include high-sulfur coal, petroleum coke, and wastes. Since that time the GTC […]

-

O&M

Projects

Reliant Energy Commits $350 Million for Environmental Upgrades at Two Key Facilities Reliant Energy has announced plans to install state-of-the-art emission control systems at two Pennsylvania power plants, a major step in the company’s strategy for maximizing the long-term value of its power generation assets while reducing air emissions. The utility, Reliant Energy, estimated it […]

-

Coal

Editorial: Tax Credits Should Help Promote Coal-Based Power Generation Technologies

In order to promote coal-based technologies, the U.S. Department of Energy will be assisting the Internal Revenue Service (IRS) in the selection of projects to receive tax credits. According to the DOE’s Office of Fossil Energy, recent legislation has been designed to advance cleaner coal-based power generation and gasification technologies. The Energy Policy Act of […]

-

Coal

Cover Story: FutureGen: Zero-Emission Power Plant of the Future

In early 2003 the United States announced its plans to build a zero-emission prototype of the fossil fuel power plant of the future called FutureGen. It is one of the boldest steps toward a pollution-free energy future ever taken by the U.S. It has the potential to be one of the most important advances in […]

-

O&M

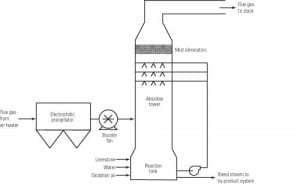

Scrubbing: Optimizing Flue Gas Desulfurization Technologies Is Essential

New flue gas desulfurization (FGD) units are being installed at utilities in many parts of the U.S. and a large percentage of the new scrubbers are of the wet limestone type. Although wet limestone scrubbing is a well-developed technology, it may be unfamiliar to employees at plants that have previously not required scrubbers. This article […]

-

O&M

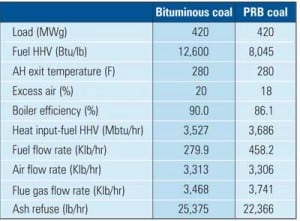

Boiler Conversion: Converting a Boiler from Burning Bituminous Coals to PRB Coals Can Be a Challenge

Design techniques and operating experience with Powder River Basin (PRB) coals have advanced significantly over the past 35 years for boilers that were originally designed for this fuel. Today, boiler installations looking to effectively utilize PRB coals fall into two primary categories: units that were initially designed for bituminous or other coals and units that […]

-

O&M

Case Histories: Co-Firing Coal and Oat Hulls Reduces Emissions at University Power Plant

The University of Iowa (UI) Biomass Fuel Project has produced significant reductions in greenhouse gas emissions, regulated boiler stack emissions, and purchased energy costs. The project utilizes a renewable, biomass fuel source and provides an opportunity for UI to partner with a local industry. UI was approached by Quaker Oats Co., Cedar Rapids Facility in […]

-

Coal

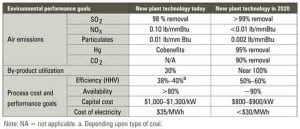

Clean Coal: Clean Coal Technology Is Not an Oxymoron

In the late 1980s, the U.S. Department of Energy (DOE), in conjunction with industry and state agencies, started the Clean Coal Technology (CCT) program. The aim of the CCT program was to develop technologies, increase efficiency, and reduce the environmental effects of burning coal in power plants. Today, pollution controls for new and existing plants […]

-

Coal

Coal Users Community: Capitalizing on Coal: The Challenges and Opportunities

Demand for energy in America continues to grow. So too does the challenge of generating it in a reliable, affordable, and an environmentally sensitive manner. Given the U.S.’s abundant coal reserves, the nation’s electric utilities are pursuing a variety of strategies to keep coal a key fuel source for generating electricity. Developing Technologies One approach […]