O&M

-

O&M

Speaking of Coal Power: Coal in a Carbon-Constrained World

Carbon capture and sequestration (CCS) have elbowed their way into the nation’s lexicon with the rise in concern over climate change. But few of the journalists who are hyping global warming have taken the trouble to learn the ins and outs of producing affordable electricity from coal. Citizens of the industrialized world now wring their […]

-

O&M

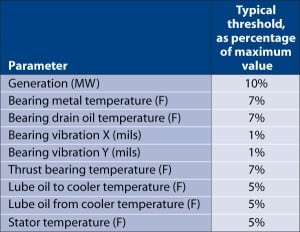

Coal Plant O&M: Continuous On-line Monitoring Cuts Downtime, Costs

As gencos seek to improve plant reliability and availability, many are turning to on-line condition monitoring for help. Huge advances in the capabilities of on-line diagnostics have occurred over the past five years. By using this technology, plant personnel can spot early warning signs of impending equipment failure and take action to correct the underlying […]

-

O&M

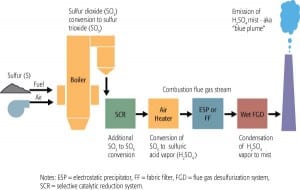

SO3 Control: Dominion Demonstrates CleanStack Technology

Dominion Generation (DG) has installed selective catalytic reduction (SCR) systems on many of the large coal-fired generating units it operates. The catalyst used has an SO2 to SO3 oxidation rate of about 1%, which roughly doubles the SO3 concentration at the outlet of the boiler economizers. The magnitude of the increase was proportional to the […]

-

O&M

SO3 Control: How Many Coal Plants Might Have Opacity Issues Due to SO3 Emissions?

Flyash and condensed sulfur trioxide (SO3) are the major components of flue gas that contribute to the opacity of a coal plant’s stack emissions (stack opacity). Estimates are that 75% to 85% of bituminous coal-fired plants with selective catalytic reduction (SCR) and/or wet flue gas desulfurization (FGD) systems are likely to produce enough SO3 vapor […]

-

O&M

Focus on O&M (February 2007)

The compliance clock is ticking / First-class maintenance in a developing country / Bypass losses squander big bucks / Revised operating procedures

-

O&M

To optimize performance, begin at the pulverizers

A systematic, performance-driven maintenance program for optimizing combustion can achieve great results. The challenge for an O&M staff is deciding which proven strategy and tactics for reducing NOx and improving plant reliability to adapt and implement. The structured approach presented here has proven its worth at several plants that have wrestled with problems similar to yours.

-

O&M

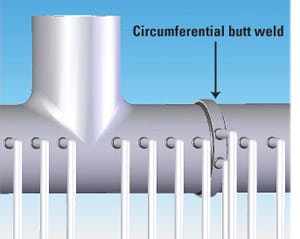

Finding and fixing cracks in high-temperature headers

The welds on superheater and reheater headers are arguably the most stressed parts of a modern steam plant. For that reason, it’s surprising that they also may be the most under-inspected. Cracks are rare, but they can be repaired if found early. One plant avoided a long forced outage to replace a reheater outlet header by using the correct condition assessments and welding techniques.

-

O&M

SO3’s impacts on plant O&M: Part II

Part I of this three-part series (POWER, October 2006) explored the negative impacts of sulfur trioxide (SO3) on the operation and maintenance of back-end plant equipment. In this issue, we list and quantify the likely and potential benefits of limiting the concentration of SO3 in flue gas to 3 ppm at the entrance to the air heater. Part III—to appear in the April 2007 issue—will describe the characteristics of an optimal SO3 removal technology and present the technical details and operating experience of one patented process that has worked successfully at a half-dozen plants for up to three years.

-

O&M

Focus on O&M (January 2007)

Mandatory standards advance / To drain or not to drain / Practical aspects of burning landfill gas / Time management

-

O&M

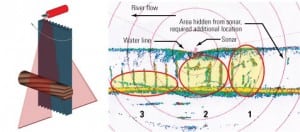

Advanced sonar revolutionizes underwater structure inspections

Ongoing maintenance is critical to the performance and longevity of underwater structures such as cooling water intake tunnels. Commercial divers or robotic vehicles can do the needed inspections, but such manual methods require a costly plant shutdown and provide only qualitative results. ASI Group Ltd. has designed and built an advanced, dual-axis sonar system that works in fast-moving water and can deliver quantitative data about the extent and location of debris buildup on submerged assets.

-

O&M

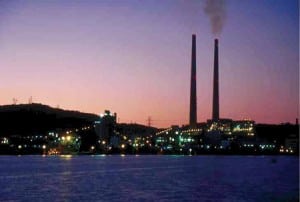

Vacuum-driven "hypo" chlorination is safer and cheaper

Safety issues related to the use of gaseous chlorine for disinfecting cooling water are pushing plant operators to examine other alternatives. Two units of Cardinal Generating Station recently switched to a liquid chlorination system, with pumpless vacuum injection, that was easy to install and has proven reliable. That switch has resulted in one less safety headache for the operations staff and one less invitation to regulatory scrutiny.

-

O&M

The Coal Patrol: Looking Back at 2006

To borrow shamelessly from Charles Dickens, one of my favorite authors, for coal in 2006, "It was the best of times, it was the worst of times." No Escape The year began in horror. On January 2, most likely a result of a severe lightning strike, methane gas in the International Coal Group’s Sago Mine […]

-

O&M

Coal Plant O&M: Elemental Analyzer Checks Quality of Delivered Coal in Real Time

When you receive a shipment, you don’t wait weeks to see whether you got what you paid for — do you? J.M. Stuart Generating Station doesn’t, but it used to. Since coming on-line in the early 1970s, the big plant, on the Ohio River near Aberdeen, Ohio, mechanically sampled coal shipments as they reached the […]

-

O&M

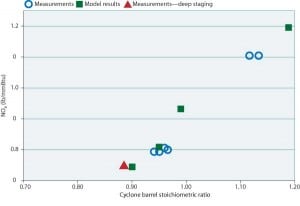

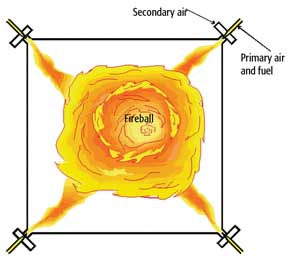

Emissions Control: Layered NOx Reduction on a 500-MW Cyclone-Fired Boiler

Historically, cyclone-fired boilers have been characterized as big emitters of NOx due to the very high temperatures in their primary combustion zone. Uncontrolled levels from 0.8 to 1.9 lb/mmBtu have been typical. The design of cyclone-fired units makes them impossible to retrofit with standard low-NOx burners. Prior to 1997, the conventional wisdom was that cyclone […]

-

O&M

Emissions Control: Cost-Effective Layered Technology for Ultra-Low NOx Control

Layering NOx control technologies can reduce a coal-fired unit’s NOx emissions to levels achievable by selective catalytic reduction alone. Advanced Combustion Technology Inc. (ACT) (www.advancedcombustion.net) has demonstrated that using several in combination can cut emissions from boilers firing eastern bituminous coal or No. 6 oil to less than 0.15 lb/mmBtu. The following two case studies […]

-

-

O&M

Focus on O&M (October 2006)

Upgrading to digital–twice / Lower-cost turbine monitoring / Pros and cons of remote process control / Nuts about Superbolt

-

O&M

Apply the fundamentals to improve emissions performance

The O&M staff of AES Westover Station wisely took a holistic approach to optimizing combustion within Unit 8’s boiler in order to reduce its NOx emissions while maintaining acceptable levels of carbon-in-ash content. The results of major modifications—centered on the addition of a fan-boosted overfire air system—were a 60% reduction in NOx levels, improved unit reliability, and a project payback period measured in months rather than years. As this project proved, the whole is more than the sum of its parts.

-

O&M

Meeting utility industry challenges through innovation

In 2005, Xcel Energy fully implemented its unique Utility Innovations initiative to encourage its IT vendors to work together. One pilot project completed under the UI umbrella confirmed that tighter integration of predictive and analytical systems and data can optimize preventive maintenance intervals, reducing costs and downtime while increasing profits and productivity.

-

O&M

Monitoring key gases in insulating oil keeps transformers healthy

Large T&D-sized transformers age as quickly as generating assets do. But preventing transformers from failing is difficult because they have no moving parts and are sealed up. Tracking the concentrations of certain gases—the more, the better—that are dissolved in a unit’s insulating oil is a proven way of detecting damage before it causes a costly problem.

-

O&M

SO3’s impacts on plant O&M: Part I

The visible consequences of sulfuric acid aerosol emissions—opaque stack emissions called “blue plumes”—are merely the tip of an iceberg. In sufficient concentration, SO3 also can increase corrosion and fouling of equipment and components downstream of the furnace while decreasing their efficiency and penalizing overall plant heat rate.

-

O&M

Focus on O&M (September 2006)

Level measurement in harsh environment;

Designing insulation for structures;

Shockingly clean boiler

-

O&M

How to conduct a plant performance test

Performance testing after initial start-up has value well beyond the short-term goal of validating equipment guarantees—it’s your only opportunity to establish the baseline performance of the overall plant and many of its major systems. Corporate bean counters may be interested in short-term results, but a good plant engineer understands that a thorough performance test will be useful for many years. Here’s your guide to each facet of a performance test—plus pitfalls to avoid.

-

O&M

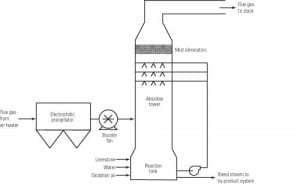

Scrubbing: Optimizing Flue Gas Desulfurization Technologies Is Essential

New flue gas desulfurization (FGD) units are being installed at utilities in many parts of the U.S. and a large percentage of the new scrubbers are of the wet limestone type. Although wet limestone scrubbing is a well-developed technology, it may be unfamiliar to employees at plants that have previously not required scrubbers. This article […]

-

O&M

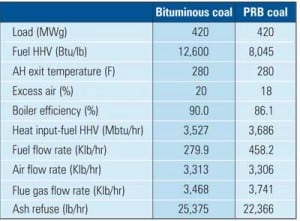

Boiler Conversion: Converting a Boiler from Burning Bituminous Coals to PRB Coals Can Be a Challenge

Design techniques and operating experience with Powder River Basin (PRB) coals have advanced significantly over the past 35 years for boilers that were originally designed for this fuel. Today, boiler installations looking to effectively utilize PRB coals fall into two primary categories: units that were initially designed for bituminous or other coals and units that […]

-

O&M

Case Histories: Co-Firing Coal and Oat Hulls Reduces Emissions at University Power Plant

The University of Iowa (UI) Biomass Fuel Project has produced significant reductions in greenhouse gas emissions, regulated boiler stack emissions, and purchased energy costs. The project utilizes a renewable, biomass fuel source and provides an opportunity for UI to partner with a local industry. UI was approached by Quaker Oats Co., Cedar Rapids Facility in […]

-

O&M

Case Histories: Asheville Power Station’s Retrofit First to Meet North Carolina’s Clean Smokestacks Act

Asheville Power Station’s Unit 1 in Arden, North Carolina, was the first coal-fired unit to be modified with a flue gas desulphurization (FGD) system and placed in service to meet the clean air requirements of the state’s Clean Smokestacks Act. As of November 16, 2005, at least 97% of the sulfur dioxide that had been […]

-

O&M

Case Histories: Synthetic Oil and Enhanced Filtration Reduce Wear and Extend Gear Life

A coal-fired power plant operating in the western U.S. was experiencing short gearbox life in its coal-pulverizing operation. After an annual gearbox inspection, oil analysis results indicated that the AGMA 6EP (ISO 320) gear oil recommended by the original equipment manufacturer (OEM) had failed to provide adequate lubrication and protection. This conclusion was based on […]

-

O&M

Projects

Reliant Energy Commits $350 Million for Environmental Upgrades at Two Key Facilities Reliant Energy has announced plans to install state-of-the-art emission control systems at two Pennsylvania power plants, a major step in the company’s strategy for maximizing the long-term value of its power generation assets while reducing air emissions. The utility, Reliant Energy, estimated it […]

-

O&M

Profiling your plant engineering staff

The latest benchmarking study by the EUCG examines the engineering and technical staffing of 62 plants, 92% of which burn coal. If you benchmark your units, plants, or fleet, the results may raise some eyebrows. But they also may help justify your plea for more intellectual capital during the upcoming budgeting cycle. Though the detailed results of the study are proprietary to EUCG member companies that participated in it, POWER was given access to the complete findings. If you want details at the plant/unit level, you’ll have to join the EUCG and participate in the study, which is ongoing.