O&M

-

O&M

Electrical Area Classification in Coal-Fired Power Plants

Electric power production from coal is on a steep rise in major developing countries, including China, India, Indonesia, South Africa, and Vietnam, albeit declining in developed countries such as the United States. Shortfalls in coal production have been reported in some of these countries, but these issues are being addressed by increasing coal production, as […]

-

O&M

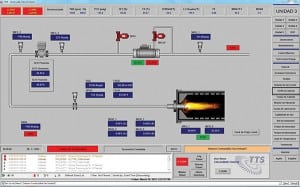

Focus on O&M: Replacing Multiple Turbine and BOP Control Systems with a Single Platform

Termoyopal, a utility based in Bogota, Colombia, recently repowered its power plant at Yopal, Colombia, by replacing three gas turbines with refurbished units and upgrading the remaining two turbines. The

-

O&M

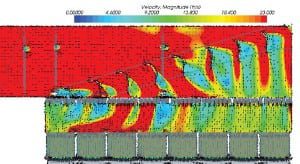

Reducing SCR Fly Ash Accumulation with Improved Reactor Inlet Airflow

The Kansas City Power & Light (KCP&L) La Cygne Generating Station provides 1,532 MW of peak power from its site south of Kansas City. La Cygne Unit 1 is an 815-MW Babcock & Wilcox cyclone boiler

-

O&M

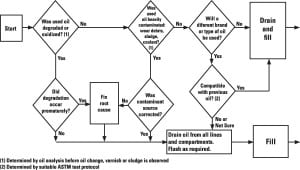

To Flush or Not to Flush, That Is the Question

Lubricating oil is the lifeblood of virtually all rotating equipment found in a power plant. Keep it clean and the lube system is relatively low maintenance. However, cycling operation and restarts after a temporary or long-term shutdown can reveal a whole new class of perhaps unfamiliar problems. The fundamental question is determining when a […]

-

O&M

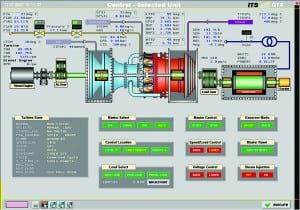

Considerations When Upgrading Gas Turbine HMIs

Aging human machine interface (HMI) hardware will eventually become a burden on plant operation. Obsolete HMIs can cause problems with connectivity, historical data loss, and hardware failure. As the hardware

-

O&M

Hybrid Inlet Chilling for Small Gas Turbines

Like any internal combustion engine, the power output and efficiency of a combustion turbine decrease as ambient temperatures rise. This loss of power and efficiency is caused by a reduction in ambient air density at higher temperatures. Since turbines are mass flow machines with a volumetrically limited intake, less-dense intake air results in degradation of […]

-

O&M

Improve Plant Heat Rate with Feedwater Heater Control

Meaningful, yet often hidden thermal performance losses occur in feedwater heaters.

-

O&M

AEP Will Retire Rather than Refuel Ohio Plant

American Electric Power (AEP) has opted to retire—instead of refueling with natural gas—its 585-MW coal-fired Muskingum River Plant Unit 5 in Beverly, Ohio, in 2015.

-

O&M

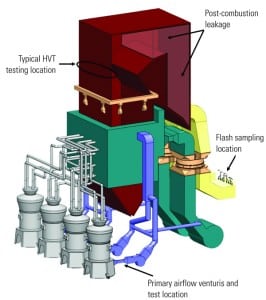

How Stealth Combustion Losses Lower Plant Efficiency. Part 1: The Problem

At the average coal-fired power plant, the battle to reduce net heat rate is complicated by skin-tight maintenance budgets, staff reductions, and—for some—the switch from baseload to mid-peaking service. The most fruitful approach to improving a plant’s heat rate is to optimize combustion in its boiler, particularly by minimizing the amount of “stealth” air in-leakage.

-

O&M

ORP: New Tool or Another Gadget?

Understand how to best use a new tool-in this case, the measurement of oxidation-reduction potential—and avoid another on-line gadget.

-

O&M

Cost Benefits of a Cycling Analysis on a Combined Cycle Unit

Cycling is a fact of life for most gas plants. But do you really understand the true costs of cycling operation? Not having a full picture risks leaving substantial money on the table.

-

O&M

Industrial Wireless Sensors: A User’s Perspective

There are many reasons to anticipate that the use of wireless instrumentation in industrial settings will increase dramatically in the next few years.

-

O&M

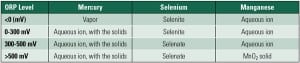

ORP as a Predictor of WFGD Chemistry and Wastewater Treatment

Recent studies have shown that system oxidation-reduction potential (ORP) is not only an important factor for predicting wet flue gas desulfurization (WFGD) absorber chemistry but also may be a predictor of process equipment corrosion and wastewater treatment requirements.

-

O&M

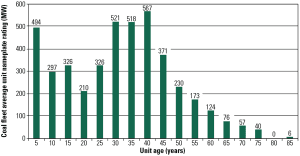

The Case for Utility Boiler Fuel Delivery System Upgrades

A vital part of any coal-fired unit is its fuel delivery system (FDS). A newly formed subcommittee of the ASME Research Committee on Energy, Environment, and Waste has investigated potential FDS upgrades on three typical 500-MW wall-, tangential-, and cyclone-fired boilers. The subcommittee has produced a series of suggested upgrades that have a simple payback of no more than two years.

-

O&M

Fighting Transformer Fires

Transformer fires are fearsome events, perhaps the most dangerous common threats to human life—both onsite and beyond the boundaries of a power plant—that can hit an electric utility.

-

O&M

Fire Protection Guidelines for Handling and Storing PRB Coal

Operators familiar with the unique requirements of burning Powder River Basin (PRB) coal will tell you that it’s not a case of “if” you will have a PRB coal fire, it’s “when.”

-

O&M

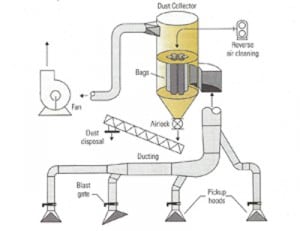

Give Your Plant a Dust Control Tune-Up

Every piece of equipment that transports or processes coal creates some level of particulate matter. Having a strategy for coal dust management in your plant is essential.

-

O&M

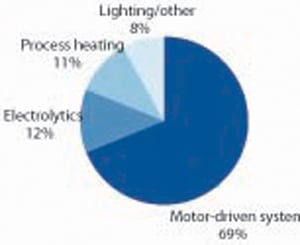

Save Money Using High-Efficiency Motors

Electric motors are the largest energy consumer within a typical industrial plant. Motors also present the greatest opportunity to reduce auxiliary loads, particularly those with high usage factors.

-

O&M

LADWP Harnesses LMS100 to Solve Once-Through Cooling Dilemma

Los Angeles sits alongside the world’s largest body of water, and naturally the city’s Department of Water & Power (LADWP) placed its generating stations along the shoreline to take advantage of that abundant resource for cooling. The LADWP built three coastal generating stations that provide the city with 2,162 MW, about 35% of the peak annual demand.

-

O&M

Improving Warm Weather Performance of the LM6000

The LM6000 is the most widely used aeroderivative combustion turbine (CT) in the world, with more than 1,000 installations. As with all CTs, power output and heat rate degrade markedly during warm weather. The ARCTIC (Absorption Refrigeration Cycle Turbine Inlet Conditioning) system eliminates this deficiency.

-

O&M

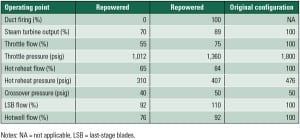

Repower or Build a New Combined Cycle Unit?

URS recently performed a combined cycle repowering study to determine the feasibility and economics of repowering an existing steam turbine that went into service in the 1950s. The competing option was building a new combined cycle unit. The results of the study provide insight for others considering the same alternatives.

-

O&M

Performance-Driven Maintenance

My career began as a results engineer testing large utility boilers. Ever since that first assignment, I have remained interested in the details of how the measurement and control of the furnace fuel and air inputs can make a huge difference in overall boiler performance. Given that plant operations and maintenance (O&M) budgets are slimmer today than in recent memory, my experience is that targeted performance testing can provide important feedback for prioritizing maintenance expenditures. The combination of plant testing and targeted O&M expenditures provide the best opportunity for efficient and reliable plant operations. I call this approach to plant efficiency improvement “performance-driven maintenace.”

-

O&M

Lithium-Ion Batteries: A Potential Fire Hazard

The proliferation of battery technologies in modern industry is presenting fire professionals with new sets of challenges. Confusion exists as to the correct approach for protecting industrial batteries from fire, whether that be in battery manufacturing, battery storage, or battery-powered applications.

-

O&M

Microbial Control in Cooling Water Improves Plant Performance

Microbial inhibition, as part of a robust cooling water treatment program, presents a special challenge because of the variability in makeup water sources, plant processes, and discharge permits. Failure to maintain a proper microbial inhibition program will affect your bottom line as a result of heat rate degradation.

-

O&M

Arc Flash Injures Three at Callaway Energy Center

Three workers were injured by an arc flash while working in the switchyard at the Callaway Energy Center in Missouri on April 2. Ameren Missouri said the accident, which happened outside the nuclear plant’s protected area, did not affect power generation.

-

O&M

Battling White Rust

Does your power plant use a chiller for combustion turbine inlet air cooling or other processes that reject heat? If so, there is a good chance you also have an auxiliary cooling tower or a wet surface air cooler to cool these systems.

-

O&M

TVA’s Paradise Unit 2 Sets New Continuous Operations Record

Paradise Fossil Plant Unit 2’s record-setting performance of 259+ days of continuous operation for a cyclone-fired boiler is attributed to excellence in plant operations and maintenance processes, a diligent and well-trained staff, and leadership that places high value on both. The Paradise experience proves that plants can’t help getting older, but they don’t have to get old.

-

O&M

Steam Turbine Rotor Vibration Failures: Causes and Solutions

Steam turbine rotors bend during operation, but the bearing and supports are designed to keep the static and dynamic forces under control. However, bending can cause impact between stationary and rotating parts—often cascading impacts. An operator of many utility-scale steam turbines shares its extensive field experience identifying the root cause of failures as well as […]

-

O&M

SNL Energy Predicts Continued Gas Switching in 2013

Dispatch competition between U.S. coal and natural gas plants has been a prominent feature of power markets since 2009. Gas prices have strengthened significantly over early 2012 levels, working to take pressure off coal plants for the upcoming year, according to a new analysis by SNL Energy.

-

O&M

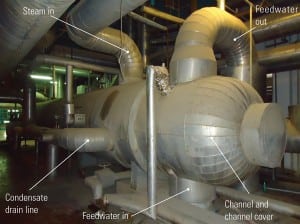

How to Avoid Feedwater Heater Drain Design Pitfalls

Feedwater heaters are used to preheat boiler feedwater by condensing steam extracted from several stages of the steam turbine. Feedwater heaters enhance the thermal efficiency of the power plant by reducing the amount of fuel burned in the boiler to produce a specified power. At the same time, the steam energy extracted from the turbine by the feedwater heater helps to reduce the rate of energy rejection to the environment via the condenser.