Environmental

-

Coal

Future of national mercury rule now uncertain

This February, a federal appeals court tossed out the Clean Air Mercury Rule and its cap-and-trade program and ordered that mercury be regulated more stringently as a hazardous air pollutant. Adding insult to injury, the court made its ruling effective one month later. While the EPA regroups, state energy and environmental regulators will have an opportunity to look closely at recent power plant permits for guidance. This article reviews the technology options and regulatory approach for mercury control used on recently permitted and currently operating coal-fired plants.

-

O&M

Focus on O&M (April 2008)

Tag-teamed seawater cleanup; New cooling towers to improve river’s health; Back to school

-

Water

Benefits of evaporating FGD purge water

In the U.S. and the European Union, scrubbers are installed on all new coal-fired power plants because their technology is considered the best available for removing SO2. A zero-liquid-discharge system is the best technology for treating wet scrubber wastewater. With the future promising stricter limits on power plants’ water use, ZLD systems that concentrate scrubber purge streams are sure to become as common as ZLD cooling tower blowdown systems.

-

Coal

Speaking of Coal Power: The True Costs of Going Green

Three of the best-kept secrets in the U.S. today have nothing to do with national security in the traditional sense. They all involve costs: the cost of fulfilling campaign promises, a valid estimate of the cost of carbon control legislation (S. 2191) expected to reach the Senate floor in a few months, and the real […]

-

Coal

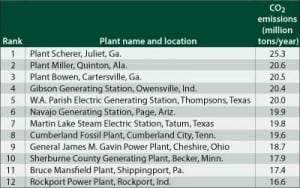

The Coal Patrol: Ranking the CO2 Emissions of the World’s Power Plants

The Environmental Integrity Project, a Washington-based advocacy group, announced in March that CO 2 emissions from U.S. power plants increased 2.9% last year over 2006 levels. The group used 2006 and 2007 CO 2 emissions data from the U.S. EPA and the DOE’s Energy Information Administration. It’s hard to normalize CO 2 numbers — and […]

-

Coal

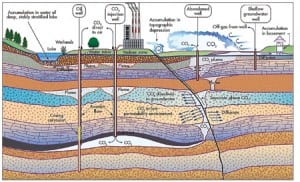

The Future of Coal Power: Modeling Geological Sequestration of CO2

Everyone in the power generation business knows that coal will continue to be a necessary fuel source for the foreseeable future. Many of those same people are beginning to understand that, politics aside, coal plant operations in the foreseeable future won’t look like the operations of yesterday or today. But what exactly will the future […]

-

Coal

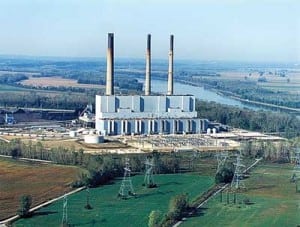

The Future of Coal Power: Development and Siting Obstacles for New Coal Plants

In recent years, Sargent & Lundy has evaluated many potential sites for new coal-fueled generation. Some of the sites studied were lands adjacent to existing power plants (brownfield sites); others were undeveloped greenfield sites. The numerous technical, environmental, economic, and regulatory issues that bear on power plant siting generally apply to both brownfield and greenfield […]

-

Coal

Emissions: Unintended Consequences of Problem-Solving

Most folks probably don’t think that power plants burning coal and ethanol — the latter touted as a having a smaller carbon footprint — have much in common. But at least one ethanol plant — Blue Flint Ethanol in Underwood, N.D. — is co-located with a coal-fired power plant in order to use its excess […]

-

O&M

Focus on O&M (February 2008)

Survey captures industry’s carbon concerns; Sequestering coal plant emissions; Comparing mercury measurement methods

-

Coal

Alstom’s chilled ammonia CO2-capture process advances toward commercialization

Carbon dioxide emissions aren’t yet regulated by the EPA, but it’s likely they will be soon. There are many technically feasible, but as-yet-undemonstrated ways to reduce the considerable carbon footprint of any coal-fired plant, whether it uses conventional or unconventional technology. One promising approach to removing CO2 from a plant’s flue gas uses chilled ammonium bicarbonate to drive the separation process.

-

Commentary

What Congress can learn from Google

Chances are good that legislation to “cap and auction” greenhouse gas (GHG) emissions will become law as early as 2009. While many environmentalists, utilities, and energy companies agree that cap and auction is the right framework, huge differences remain. Environmentalists want an 80% reduction of GHG emissions by 2050, or sooner. Energy companies want more […]

-

Coal

Global Monitor (January 2008)

Dominion applies for new Virginia reactor / ABB commissions world’s largest SVC / Google Earth adds air quality data / Alstom supplies integrated solar/CC project in Morocco / DOE updates coal plant database / Dam the Red Sea? / Complying with CWA Section 316

-

Coal

Speaking of Coal Power: With Chaos Comes Opportunity

Combat veterans use the phrase "fog of war" to explain why carefully prepared battle plans are quickly overwhelmed by chaos once the first bullet is fired. Survivors often describe experiences that are markedly different from those of others standing only yards away. The fog of our industry’s battle to build new generating plants permeates the […]

-

Coal

FutureGen: FutureGen Finds a Home But Can’t Pay the Mortgage

The FutureGen Industrial Alliance Inc. selected Mattoon, Ill., as the site of the $1.8 billion FutureGen project just before Christmas, but the plant may never move off the drawing board.. FutureGen, the proposed prototype of a near-zero-emissions coal plant, is to demonstrate advanced technologies for coal gasification, electricity production, emissions control, CO 2 capture and […]

-

Coal

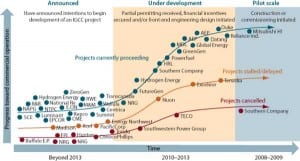

IGCC: IGCC’s Future Hinges on a Workable Carbon Framework

Integrated gasification combined-cycle (IGCC) technology, a process of gasifying coal that allows the capture of carbon dioxide emissions, has tremendous potential for meeting future baseload generation demand. Though it is one of the leading alternatives for producing clean power from coal, IGCC faces a precarious future due to rising capital costs and regulatory uncertainty. We’re […]

-

O&M

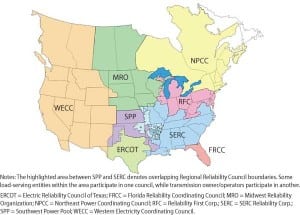

The Coal Patrol: Demand Growth — and Reliability — Are Still Supply-Limited

While noting marginal improvements since last year, America’s power reliability watchdog recently warned that the nation’s growing thirst for electricity will still far exceed planned increases in generation capacity over the next 10 years, and that reserve margins could dip below optimal levels within two or three years in California, the Rocky Mountain states, New […]

-

Coal

The Coal Pile: Dreaming of a Green Christmas

On November 20, New York City Mayor Michael R. Bloomberg and top executives of the real estate company Tishman Speyer announced several energy conservation measures to be implemented at Rockefeller Center this holiday season. One is the outfitting of its famous Norway Spruce Christmas tree with 30,000 light-emitting diodes (LEDs) strung on five miles of […]

-

Coal

Coal Plant O&M: Retrofit Flyash-Handling System Pays Dividends

Like many older coal-fired plants, Westar Energy’s Jeffrey Energy Center (JEC) was built with traditional, pneumatic flyash-handling and removal systems. Such systems collect flyash in hoppers attached to the bottom of a unit’s electrostatic precipitator (ESP) and/or baghouse. Periodically, the hoppers are emptied into tanks and the flyash is conveyed away for disposal or beneficiation. […]

-

Coal

Speaking of Coal Power: Polar Bear Politics

During his June 2007 speech to the National Press Club, presidential candidate and former U.S. Senator John Edwards called America’s 37 million residents living below the poverty line "the great moral issue of our time." He proposed setting a national goal of ending poverty in 30 years. The Heritage Foundation, a conservative think tank, disputed […]

-

Coal

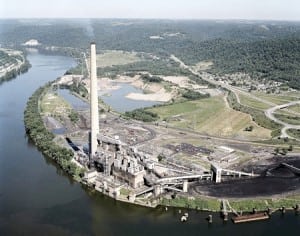

R.E. Burger Plant, Shadyside, Ohio

FirstEnergy’s R.E. Burger Plant has hosted a number of R&D projects over the years, but none as large as the demonstration of Powerspan’s 50-MW Electro-Catalytic Oxidation (ECO) multipollutant removal process a few years ago. Credit Powerspan for scaling up the demo unit and for adding CO2 as a target of a new pilot process called ECO2. And don’t forget the behind-the-scenes support of Burger’s plant staff and their willingness to incubate R&D projects while producing power. That’s what makes R.E. Burger a Top Plant in our book.

-

Coal

Global Monitor (October 2007)

Siemens ships first blade from U.S. plant; GE’s frames hit 1,000; Battery problems hit hybrid EV programs; Solar thermal rebounds in California;Peabody’s Illinois coal plant gets green light;EPA could sink 278-MW CFB unit; Longest-serving NRC commissioner dies at 58; POWER digest; Readers talk back; corrections

-

Commentary

What is resource adequacy?

Under its Resource Adequacy (RA) program, the California Public Utilities Commission (CPUC) requires load-serving entities—both independently owned utilities and electric service providers—to demonstrate in both monthly and annual filings that they have purchased capacity commitments of no less than 115% of their peak loads. These purchase requirements are intended to secure sufficient commitments from […]

-

Coal

IGCC demonstration plant at Nakoso Power Station, Iwaki City, Japan

Integrated gasification combined-cycle (IGCC) power plants are not yet standard designs. Although they use mature coal gasification processes and combustion turbines, disparate technologies and equipment still require custom, laborious interfacing at each site. Every major gas turbine vendor now can point to one or more power-producing IGCC projects based on its prime mover, but none yet offers a "reference" plant that has standardized the interfacing enough to justify confidence in two key metrics: $/kW and availability. With an air-blown demonstration plant based on one of its 130-MW turbines, Mitsubishi Heavy Industries is looking to change the rules of this game.

-

Coal

Pleasant Prairie Power Plant Air Quality Control Upgrade Project, Pleasant Prairie, Wisconsin

We Energies’ Pleasant Prairie Power Plant is a good example of how existing plants retrofitted with NOx and SO2 removal systems benefit from early planning and action. P4, as everyone calls it, recently completed a multiyear project to add a selective catalytic reduction system to one of its two units and a scrubber to both. The unique design and contracting aspects of the project make Pleasant Prairie one of POWER’s top coal-fired plants of 2007.

-

Coal

Polk Power Station Unit 1, Mulberry, Florida

Ten years ago, POWER selected Tampa Electric’s 250-MW Polk Power Station and its revolutionary integrated gasification combined-cycle demonstration project as the magazine’s 1997 Plant of the Year. Although no new commercial IGCC projects have been built since then, interest in deploying the coal-gasification technology is getting traction in some parts of the U.S. In 2007, POWER recognizes Polk Unit 1 as a Top Plant for developing trailblazing O&M practices and technical improvements that enable it to operate today as reliably as a modern pulverized coal plant, with lower pollutant emissions.

-

Coal

Speaking of Coal Power: BACT to the Future

This August, Peabody Energy’s 1,600-MW Prairie State Energy Campus project in Illinois won a major federal appeals court decision, removing the last obstacle to groundbreaking. The six-year regulatory review process ended with an unsuccessful Sierra Club challenge to the $2.9 billion project’s air permit. The decision is sure to reverberate across the nation, and I […]

-

Coal

PRB Tech Notes: AmerenUE Teams with Charah and Home Depot to Market Ash for Concrete Mix

Burning Powder River Basin (PRB) coal can be a curse or a blessing, depending on your attention to the details of plant design and operations. One disadvantage of PRB coal combustion is the abundance of bottom ash and flyash generated as a by-product. Handling and properly disposing of the ash can be challenging and costly. […]

-

Coal

Coal Plant O&M: How Switching to PRB Lowered O&M Costs

Lansing Board of Water & Light (LBW&L), which has generated electricity since 1892 and steam since 1919 in mid-Michigan, primarily serves the city of Lansing’s business district and all state government buildings in the downtown area. But one of the municipal utility’s plants, Moores Park, has an additional and very important steam customer: General Motors’ […]

-

O&M

Mercury Control: Capturing Mercury in Wet Scrubbers: Part II

In Part I of this two-part report ( COAL POWER, July/August 2007, p. 22), we introduced the integrated R&D effort by the U.S. Department of Energy’s National Energy Technology Laboratory (DOE/NETL) to improve understanding of the mechanisms of mercury (Hg) capture and retention in flue gas desulfurization (FGD) systems and the fate of Hg in […]

-

Environmental

Field experience with mercury monitors

With U.S. mercury regulations pending and control technologies in the full-scale demonstration stage, accurate and reliable measurement of mercury in flue gas is becoming more important than ever. This article compares the results of field measurements of commercially available mercury monitors to approved reference methods. A key but not-so-surprising finding: Not all mercury monitors are created equal.