Technical Guidance Documents Provide Global Standards

The International Association for the Properties of Water and Steam (IAPWS) is an international nonprofit association of national organizations concerned with the properties of water and steam, particularly thermophysical properties and other aspects of high-temperature steam, water, and aqueous mixtures that are relevant to thermal power cycles and other industrial applications.

The group’s objectives are:

■ To provide internationally accepted formulations for the properties of light and heavy steam, water, and selected aqueous solutions for scientific and industrial applications.

■ To provide technical guidance, obtained by international consensus of experts, on cycle chemistry and technology for steam power cycles in fossil and combined cycle plants and other industrial applications.

■ To define research needs, and promote and coordinate research on steam, water, and selected aqueous systems important in thermal power cycles.

■ To collect and evaluate the resulting data, and to communicate and promulgate the findings.

■ To provide an international forum for exchange of experiences, ideas, and results of research on high-temperature aqueous media.

Bringing Engineers and Scientists Together

The IAPWS is organized as an association of member countries. The current members are Britain and Ireland, Canada, Czech Republic, Germany, Japan, New Zealand, Russia, Scandinavia (Denmark, Finland, Norway, and Sweden), and the U.S. Associate members are Argentina and Brazil, Australia, Egypt, France, Greece, and Switzerland.

The group held its annual meeting September 11–16, 2016, in Dresden, Germany. The primary purpose of the annual meeting is to connect researchers and scientists with the engineers who use their information. This information exchange provides the researchers with guidance on topical problems within the industry and provides the engineers with the latest research results.

Areas of application include power cycle chemistry (PCC), high-temperature aqueous technologies applicable to steam cycles and fuel cells, the use of high-temperature water and supercritical steam in chemical and metallurgical processes, supercritical synthesis of new materials and destruction of toxic wastes, hydrothermal geochemistry, hydrometallurgy, oceanography, power cycles with CO2 capture and storage systems, and combined heat and power systems, including district heating.

The IAPWS produces releases and guidelines on the recommended scientific formulations for physical and chemical properties of water in its various forms as well as technical guidance documents (TGDs) that are the concerted opinion of the IAPWS members on best operating practices for power plant chemistry. The IAPWS also documents “certified research needs,” identifying particular subjects that require research to fill a current gap in knowledge. All of this information is freely available and can be found on the IAPWS website (www.iapws.org).

New Technical Guidance Documents

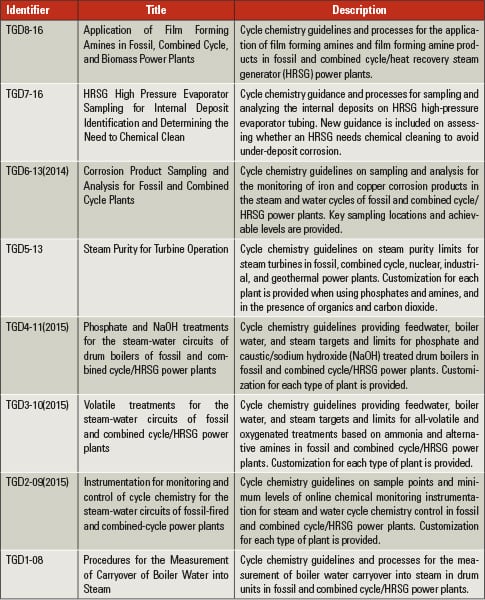

During the PCC working group meetings in Dresden, two new TGDs were approved for release: “Application of Film Forming Amines in Fossil, Combined Cycle, and Biomass Plants” and “HRSG High Pressure Evaporator Sampling for Internal Deposit Identification and Determining the Need to Chemical Clean.” The new documents brought the total number of TGDs available to eight (see Table 1).

In order to control corrosion throughout the water/steam circuits of fossil and combined cycle/heat recovery steam generator (HRSG) plants, it is essential for the operator of a plant to choose and optimize a chemical treatment scheme that is customized for that plant. The “Application of Film Forming Amines in Fossil, Combined Cycle, and Biomass Plants” TGD addresses the use and application of chemicals referred to as film-forming amines (FFAs) for this purpose.

As well as providing background information on FFAs, the document includes guidance for determining if an FFA should be applied, the tests required before application, the locations for the addition, the optimum dosage level, and the tests to determine the benefits of applying FFAs. The TGD emphasizes that, depending on local plant requirements, the application of FFAs will need to be customized for each plant, depending on the actual operating conditions, the equipment and materials installed, and the condenser cooling media.

The “HRSG High Pressure Evaporator Sampling for Internal Deposit Identification and Determining the Need to Chemical Clean” TGD includes new guidance for understanding waterside deposits in the high-pressure (HP) HRSG evaporators of combined cycle plants. This is important because, together with flow-accelerated corrosion, under-deposit corrosion (UDC) is one of the leading mechanisms of failure and damage in HRSG circuits.

Many of the failure and damage mechanisms in combined cycle plants are influenced by the transport to, and deposition of, corrosion products within the HP evaporator. This TGD provides a new approach to determine the critical deposit loading to avoid UDC in HP evaporators and new rationales for determining the need to clean HRSGs. By using the optimum chemical treatments delineated in the other IAPWS TGDs, it is expected that the magnitude of internal HP evaporator deposits and the need for chemical cleaning will be significantly reduced.

Alternatively, if non-optimum treatments are used or extended layup procedures are inadequate, the deposits may exceed a critical deposit loading or thickness, and there could be concentration of harmful contaminants within the deposits with potential for subsequent failure or damage. This document provides guidance on where to sample, how to analyze HP evaporator tubes, and how to determine if the HRSG needs chemical cleaning through the use of a new deposition map.

While in Germany, the PCC working group discussed the development of new TGDs involving demineralized water requirements and the use of FFAs in nuclear plants. It is also developing white papers on corrosion product sampling for plants in flexible operation and on minimizing air in-leakage into steam-water cycles. ■

—Edited by Aaron Larson, POWER associate editor.