Modern Polymeric Materials Offer Options for Equipment Repair

Continual development of polymer technology has enabled the creation of specialized coatings, which can offer excellent resistance to erosion, corrosion, and cavitation in hydroelectric equipment and pumps at any generating plant. Polymeric materials can also increase efficiency and extend runtimes.

Currently accounting for over 16% of global energy production, and with an expected growth rate of 3% per year for the next quarter century, hydroelectric power generation continues to grow as the front runner in renewable energy, even though growth in the U.S. is expected to be minimal.

In recent years, maintenance of existing hydroelectric assets has become increasingly important to ensure a consistent supply of power. Low water levels, due to factors such as drought and higher local demand for water (see “Water Issues Challenge Power Generators” in the July 2013 issue of POWER, online at powermag.com), have resulted in decreased production in high-profile hydroelectric stations, such as the Hoover Dam. There the problem has become so severe that the resulting drop in pressure difference has caused increased cavitation damage to turbine runners and a 20% decrease in production levels.

Ensuring turbine efficiency and up-time are at their maximum is key to achieving optimum production. However, as with any fluid flow equipment, the effects of erosion and corrosion will detract from this. If left unchecked, erosion—and specifically, cavitation damage—rates increase exponentially to cause severe metal loss. Unbalancing and vibration of turbine runners can result, requiring lengthy shutdowns for repair work to shafts and bearings. Loss of surface smoothness also results in increased turbulent flow and lower production rates.

Traditional Repair Techniques

The recommended procedure for determining inspection and repair frequency for hydroelectric runners and turbines, including stay vanes and wicket gates, is to inspect the equipment at set intervals following installation to ascertain the rate of damage, including erosion, corrosion, and cavitation. Once the rate of damage is known, procedures are put in place to repair the damage once the depth of metal loss reaches predetermined levels.

Once a maintenance routine is put in place, repairs are carried out in accordance with the recommended procedure. The procedure is often to replace the lost metal using conventional metal replacement techniques. Large areas of pitting are repaired by welding plates or sheets of new metal in place as an erosion wear layer, whereas areas of lighter damage are repaired by weld overlay, which is then ground back to the correct tolerance. The procedure is repeated at the next service interval, as dictated by the rate of in-service deterioration.

Limitations of Traditional Repairs

The traditional repair procedure is not without problems though. The most basic flaw is the replacement of the material that is being lost with more of the same material—a like-for-like repair. Reintroducing the same base material simply allows the problems to reoccur and does not identify the root cause of the issue and work to limit its effects. Continued metal loss will result in continued shutdowns. As previously discussed, metal loss will in some cases result in vibration due to imbalance, and this can cause damage to bearings and shafts.

One of the major drawbacks of using hot work to replace lost metal is the procedure involved in implementing the repair. According to the Facilities Instructions, Standards, & Techniques Turbine Repair manual, “Extensive weld repairs can result in runner blade distortion, acceleration of further cavitation damage, and possible reduction of turbine efficiency. Also, extensive repair can cause residual stressing in the runner resulting in structural cracking at areas of high stress.”

Coupled with this is the complexity of carrying out hot work repairs. Extensive rigging and supports are recommended in order to avoid distortion of finely honed parts. Hot work is recommended to be carried out gradually, heating up the entire part first prior to application of the repair technique, and lengthy cooldown times are required after application of the repair to avoid excessive heat distortion. Care is also required when selecting the repair metal (plates or welding rods), as different materials can introduce local galvanic corrosion, initiating even more repair requirements.

A Better Alternative: Coatings

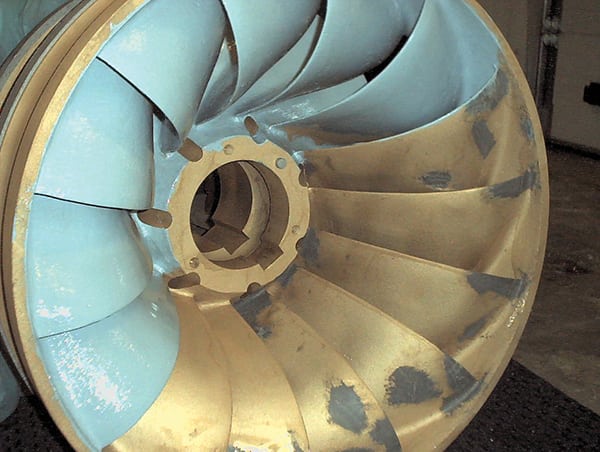

Modern polymeric repair systems offer an excellent alternative to traditional repair materials. These materials are supplied in either paste grade filler type repair composites used to infill damaged areas and restore profiles (Figure 1) or as coating grade products used to provide long-term protection to equipment against specific damage. Advanced polymeric coatings completely halt corrosion by isolating the metals and closing the corrosion cell.

|

| 1. Completed replacement of leading edges damaged by cavitation. Courtesy: Belzona Polymerics Ltd. |

Polymeric coatings have been used for more than 60 years in many different applications, such as on hydroelectric generation equipment, offshore and onshore oil and gas systems, pumps, and sewage treatment equipment, and they have a reliable track record in these environments. By utilizing solvent-free epoxy technology, these products are safe to use, even in enclosed spaces.

Specialized filler materials, such as ceramics and aluminium oxide, allow epoxy coatings to achieve good wear resistance. Epoxy coatings combine with the metallic substrate to provide a composite component, which offers ongoing maintenance advantages.

Application Advantages

Prior to application, thorough surface preparation is required in the area to be repaired. This is commonly achieved using localized grit blasting to clean and roughen the metal, which allows the polymer to form an intimate bond with the base metal.

Polymeric repair and coating composites, such as Belzona, are supplied as two-part products. The components are mixed prior to application using spatulas and bowls or with paddle mixers for larger projects. This mixing initiates the chemical reaction, which enables the product to solidify to its final form.

Application is commonly carried out using trowels for paste grade rebuilding composites and by brush for coating grade epoxies (Figures 2 and 3). Many products can also be applied by airless spray, allowing for rapid repair times over large areas. The product is then allowed to cure for a period of time before the equipment can be returned to service.

|

| 3. Ready to run. After coating application, this runner is installed and ready to return to service. Courtesy: Belzona Polymerics Ltd. |

Because modern epoxy polymer materials are cold-curing, they eliminate the requirement for hot work that is needed for traditional repair techniques. This avoids problems, such as:

- Risk of equipment distortion.

- Requirement for specialist rigging and jigs.

- Lengthy repair times required to allow for cooling of welds.

- Grinding and finishing of weld overlay.

- Health and safety hazards associated with hot work.

- Need for specialist welding rods and expensive replacement metal.

- Introduction of heat-affected zones due to welding.

- Lengthy shutdown times.

Use of epoxy composites as a protective coating for the base metal also allows for much easier wear identification in the future, as different-colored layers of polymeric coatings allow wear areas to be quickly identified. Repairing existing coatings is a straightforward process; an area can be prepared using powered hand tools before a patch repair is applied.

Advanced application methods, such as airless spray equipment, have allowed even faster repair times. Turbine casings, draft tubes, and outlets are all subject to the same damage as the turbine runner and can be repaired using the same epoxy polymer products. The newest generation of epoxy coatings incorporate advanced polymer fillers, which provide improved erosion resistance while allowing application by airless spray, which is ideal for larger areas.

Several polymer coatings have been specially developed by Belzona for applications in pumping and hydroelectric generation, which specifically aim to improve efficiency and reduce cavitation.

Efficiency Enhancement

Increasing the efficiency of existing equipment allows asset owners to get the most from their equipment. One of the most effective methods of improving asset performance is by applying coatings that will reduce resistance to flow caused by friction with the substrate. Belzona 1341 (Supermetalglide) is an epoxy coating with a low electronic affinity with water molecules (making it a hydrophobic material). Once applied, it forms an extremely smooth surface, which reduces the boundary layer of the pumped fluid and reduces internal turbulence in the flow, thus increasing hydraulic efficiency.

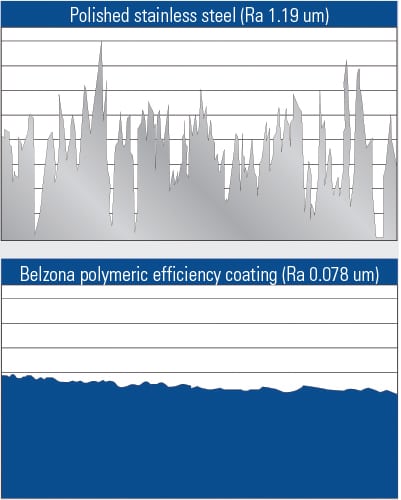

A Leeds University surface inspection study found that Belzona 1341 (Supermetalglide) was 15 times smoother than polished stainless steel (Figure 4). Incorporation of ceramic fillers also allows the coating to resist erosion and protect the equipment for long service periods.

|

| 4. No comparison. A Leeds University surface inspection study found that polished stainless steel was far less smooth than Belzona 1341 (Supermetalglide). Courtesy: Belzona Polymerics Ltd. |

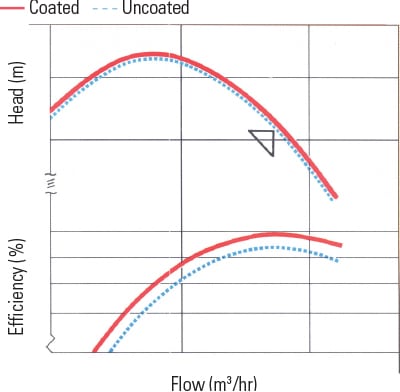

Testing conducted in the United Kingdom by the National Engineering Laboratory showed that applying Belzona 1341 (Supermetalglide) to a new pump increased peak efficiency by up to 6% (Figure 5). At this peak efficiency point, the reduction in power consumption has been measured at 5.1 kW at duty point. Assuming a 5,000-hour operating cycle per year, power savings would amount to 25,500 kWh per year.

|

| 5. Increased efficiency. These performance curve results were recorded by the UK National Engineering Laboratory. Courtesy: Belzona Polymerics Ltd. |

Similar efficiency gains can be expected in hydroelectric equipment. On existing, in-service equipment, the increase will commonly be even higher. Equipment that has suffered from heavy deterioration and loss of efficiency can be returned to better than original performance. On heavily deteriorated pumps repaired by the City of Fayetteville, Ark., an improvement of 17% was recorded compared to the deteriorated condition performance.

Resisting Cavitation

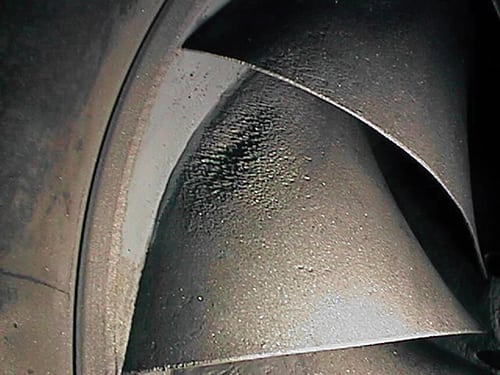

Occurring in areas of pressure change across fluid flow equipment, cavitation is one of the most damaging and difficult forms of erosion encountered in hydroelectric equipment. Rapid implosion of vapor bubbles close to the metallic substrate results in powerful micro-jets that impact and “chip” the base material, resulting in pocketed erosion (Figure 6).

|

| 6. Heavy loss. Cavitation damage has resulted in severe metal loss on these impeller vanes. Courtesy: Belzona Polymerics Ltd. |

Use of hard materials and specialty alloys is common practice in areas of cavitation, but these measures are often very expensive and can also fail under constant attack. In order to resist the effects of cavitation, Belzona specially developed Belzona 2141 ACR Elastomer. This is a two-part elastomeric polymer applied using a brush as a coating specifically to areas subject to cavitation damage.

Belzona 2141 ACR Elastomer followed a lengthy development and research process to determine the key conditions present in cavitation areas on fluid-handling equipment. Exceptional bond strength, resistance to temperature, and the ability to absorb the extreme impact pressures from micro-jetting were all requirements fulfilled by Belzona’s elastomeric polymer material (Figures 7, 8, and 9).

|

| 7. Original condition. This photo shows the initial condition of a Francis turbine runner following grit blasting. The pitting damage is due to cavitation. Courtesy: Belzona Polymerics Ltd. |

Extensive independent testing, in accordance with American Society for Testing and Materials (ASTM) standards, yielded exceptional results. A Voith–Siemens report showed the material resisted damage after 500 hours of intensive cavitation testing. Penn State University evaluated the product at 130 knots of intensive cavitation testing and reported resistance without damage after 20 hours. Samsung reported that ASTM G32 results for Belzona 2141 were significantly higher than for 316L stainless steel.

Field applications—to turbines, wicket gates, stay vanes, and turbine shafts—that are still providing excellent performance after a decade of service are testament to the material’s longevity. ■

— Kyle Flanagan ([email protected]) is a technical services engineer for Belzona Polymerics Ltd.