Mercury Regulations Up in the Air

U.S. Environmental Protection Agency efforts to regulate mercury emissions from coal- and oil-fired power plants have spanned nearly two decades. In February of this year the agency promulgated the Mercury and Air Toxics Standards, but changes to the standards continue.

The Mercury and Air Toxics Standards (MATS) formally impose limitations on mercury, filterable particulate matter, and hydrogen chloride emissions from electric generating units (EGUs) firing coal (including integrated gasification combined cycle, or IGCC, facilities), solid oil, and liquid oil. In addition to a variety of available control technologies to meet MATS, new technologies that allow measurement of more minute quantities of mercury will be necessary to ensure compliance.

Regulatory History

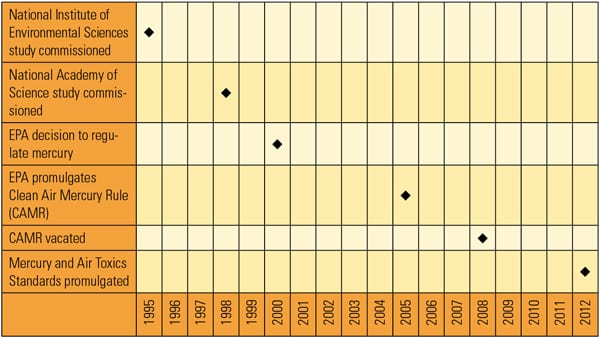

The basis for MATS dates back to two studies funded by the Environmental Protection Agency (EPA) and required by the Clean Air Act (CAA). In 1995, as directed by Congress, the National Institute of Environmental Sciences (NIEHS) issued a report detailing the threshold of mercury exposure below which adverse human health effects are not expected to occur. Several years later, the National Academy of Sciences (NAS) was commissioned to perform an independent evaluation of the health impacts from methyl mercury. The results of this study were finalized and released by 2000, thus satisfying the CAA Section 112 (n)(1) requirement to evaluate the hazards to public health from mercury emissions.

In total, the expected number of units that will be affected by this regulation is large. There are approximately 1,100 coal-fired units and 300 oil-fired units that would need to meet compliance by three years from the finalization of this rule. Each facility may request a one-year compliance extension, which states may grant on a case-by-case basis.

However, a recent judicial ruling regarding another key regulation, that found the EPA overstepped its bounds, could lead to further scrutiny of the MATS regulation. The decision by the U.S. Court of Appeals for the District of Columbia Circuit on Aug. 21, 2012 ( EME Homer City Generation v. EPA, D.C.C. No. 11-1302) dealt a significant blow to the Cross State Air Pollution Rule (CSAPR), as it was vacated and determined that the EPA had regulated beyond its statutory authority. The court determined the EPA overstepped its bounds in two key ways.

First, under the “good neighbor” policy, the EPA has the authority to require upwind states to reduce their emissions that affect a downwind state’s nonattainment. It was determined that CSAPR required upwind states to reduce their emissions by more than the amount that ultimately affected downwind states. Second, the court found that states should have been allowed to reduce their own emissions through a state implementation plan (SIP). Instead, the EPA did not give the states this option and enacted a federal implementation plan (FIP) to reduce emissions on a state level.

A great deal of effort was made by the EPA to ensure CSAPR would be upheld under legal review. MATS may succumb to a similar fate, as multiple parties have filed for review of the rule by the courts. It should be noted that EPA regulations have a history of litigation, with a mixed record of courts upholding them or rejecting them. At press time, the EPA and intervenors, including Calpine and Exelon, had petitioned for a rehearing of the court’s Aug. 21 split decision against CSAPR. The court has ordered 20-page responses to the petition for rehearing be filed with the court by Oct. 29. The court has no timeline within which to decide to reject the petition, rehear the case with another three-judge panel, or hear the case en banc with all eight judges.

Costs are expected to increase considerably for implementing the MATS regulation. According to the EPA’s Regulatory Impact Analysis (RIA), the incremental cost of compliance with MATS in 2015 will be $9.6 billion per year. As part of the RIA, the EPA estimated that capital costs to meet both CSAPR and MATS would have been $84 billion. Recent cost estimates by some major utilities suggest that the cost to comply may be lower than originally estimated. Even with the vacating of CSAPR and positive estimates from utilities, final compliance costs are a moving target, leaving the number of potential plant closures up in the air.

|

| 1. History review. Milestones in the regulation of mercury. Source: EPA |

Mired in Litigation

As a result of the NIEHS and NAS analyses, the EPA concluded in December 2000 that regulating hazardous air pollution emissions—specifically mercury—was appropriate and necessary. That determination triggered a series of legal actions that were individually resolved over the following decade. This process led to the eventual promulgation of MATS.

After the initial determination that regulating mercury was appropriate and necessary, the Utility Air Regulatory Group (UARG) and Edison Electric Institute (EEI) challenged this determination in court ( UARG v. EPA, 2001 WL 936363, No. 01-1071, D.C. Cir. July 26, 2001). The case was dismissed on jurisdictional grounds.

Mercury regulation was still deemed appropriate and necessary and, consequently, the EPA was required to set rules for EGUs as a result of the agency adding them as a source category, as described in Section 112 of the CAA. As required by the CAA, the deadline for the mercury rule’s revision was Dec. 20, 2002. However, the EPA failed to meet that deadline. As a result, several environmental groups filed suit to compel the EPA to issue emission standards for EGUs ( Izaak Walton League v. Leavitt, D.D.C. No. 04-0694). The deadline for the standard to be issued then became Mar. 15, 2005.

Instead of issuing a rule for Section 112 of the CAA for EGUs, the EPA subsequently issued an action on Mar. 29, 2005, that delisted EGUs from Section 112 regulation. Shortly after the delisting action, the EPA issued the Clean Air Mercury Rule (CAMR), on May 18, 2005. That rule was meant to regulate mercury emissions from new and existing coal-fired EGUs under Section 111 of the CAA. Again, environmental groups and states took issue with the EPA’s delisting without following requirements outlined in Section 112.

The result of that legal challenge ( New Jersey v. EPA, 517 F.3d, D.C. Cir. 2008) reversed both actions taken by the EPA in 2005: The delisting action in March and the subsequent CAMR issuance in May. In striking down CAMR, the court simply postponed but did not negate implementation of mercury regulations. Furthermore, reversal of the delisting action further confirmed the EPA’s obligation to finalize emission standards under Section 112 of the CAA.

In order to ensure an emission standard was issued in a timely manner, environmental groups once again filed suit to seek enforceable deadlines on the EPA ( American Nurses Association v. EPA, DDC No. 08-2198). The result of this suit set a deadline of Nov. 16, 2011, for a finalized air toxics standard. Pursuant to this settlement, the EPA signed the promulgated MATS rule on Dec. 16, 2011, and published it in the Federal Register on Feb. 16, 2012.

True to the history of this regulation, litigation resumed as soon as MATS was signed. White Stallion, the National Mining Association, the National Black Chamber of Commerce, and the Institute for Liberty all filed suit the same day as MATS was finalized. These suits have not been resolved and have been consolidated into a single action.

Reconsideration of MATS

In June 2012, Senator James Inhofe (R-Okla.) introduced a motion in Congress that would have overturned the MATS regulation. This motion (Senate Joint Resolution 37), put forth under the Congressional Review Act, could have sent the regulation back to the EPA to be rewritten under congressional review. However, when brought before the Senate on June 19, the resolution was narrowly defeated.

Although not required by Congress, the EPA took action on July 20 to review MATS. The EPA issued a letter acknowledging that a number of petitions had been received specifically addressing measurement issues associated with mercury for new sources. In addition to addressing measurement problems with mercury, the data set used to set new source standards for particulate matter and hydrochloric acid will be revisited to ensure variability calculations were applied correctly.

The issues to be reviewed will be mostly technical in nature and are not expected to affect the rule’s legality. An expedited review process has been initiated. However, final reconsideration of the rulemaking will not be complete until March 2013. In the meantime, a stay of three months was given by the EPA for the effective date of the new source emission standards.

MACT Floor

Once a source category is listed by the EPA under Section 112 of the CAA, the agency must establish technology-based emission standards, known as maximum achievable control technology (MACT). These standards are based on technology currently available. Due to the variability in performance between older units and new units, the MACT analysis may set different standards for existing and new sources.

When determining what is considered to be MACT, the EPA must calculate something called the “MACT Floor.” For existing units, the MACT Floor is determined by analyzing a set a data containing the average emissions for a particular pollutant. Using this set of data, the EPA then determines what level of emissions can be met by the best performing 12% of the data set.

This emission target is the MACT Floor, and that target becomes the minimum value that all other existing units must conform to. In the event that there are fewer than 30 sources for which data is available, the EPA will isolate the best five performing units and set that as the MACT Floor.

When determining the MACT Floor for a new source, the approach is different. In that case, the MACT Floor would be set by the “emission control achieved in practice by the best controlled similar source.”

Unfortunately, determining what the MACT Floor is doesn’t necessarily set what the final MACT limits will be. Upon defining the MACT Floor, the EPA must then consider a more stringent “beyond-the-floor” option that pushes control technology to perform at levels below the MACT Floor emission level. As a result of previous litigation ( Cement Kiln Recycling Coal v. EPA, 255 F.3d 855, 857-58, D.C. Cir. 2001), this analysis must also take into account costs, energy, non–air quality health, and environmental impacts.

In the case of the MATS regulation, the EPA chose to set mercury emission limits for most units at the MACT Floor limit. However, some units will be required to reach below-the-floor limits. In the case of existing units that utilize a low-rank virgin coal for power generation, the EPA determined that the MACT Floor emission limitation was 11 pounds per trillion Btu. The agency also determined that, based on the availability of activated carbon injection (ACI) systems, the incremental cost of further reduction is “reasonable.”

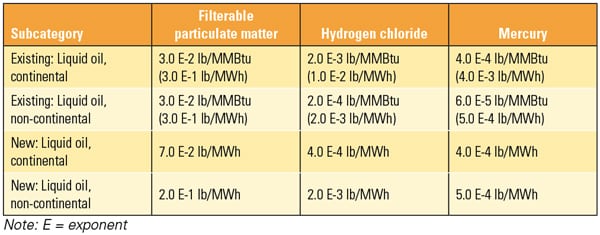

From this conclusion, the EPA decided that a limit 64% below the MACT Floor was appropriate, resulting in a limitation of 4 pounds per trillion Btu for existing units using low-rank virgin coal. This means that those units will now be required to perform at the same level as a new unit. And although new units have been granted a stay of effective dates while the EPA reevaluates technical issues associated with mercury, existing units are required to maintain the original compliance dates (Tables 1 and 2).

|

| Table 1. Emissions limitations for coal and solid oil-derived fuels. Source: EPA |

|

| Table 2. Emissions limitations for liquid oil fuels. Source: EPA |

Measurement Techniques

The promulgation of MATS created more than just the issue of how to control these pollutants. It also addressed the issue of how to measure the pollutants being emitted. As mentioned previously, the EPA has already acknowledged potential problems with measuring low emission levels for pollutants such as mercury, and therefore granted a stay for new units. Multiple options exist for measuring mercury, and each unit will have to be individually evaluated to determine which option will obtain the desired level of accuracy.

Typically, a continuous emission monitoring system (CEMS) for mercury or a sorbent trap system meeting the EPA’s Performance Standard 12B is required. Maintenance of a mercury CEMS system is very labor-intensive, with high operating costs, particularly for calibration gases for maintaining system accuracy. Also, each new mercury measurement system requires initial certifications, initial linearity checks, daily calculations, weekly integrity checks, and quarterly linearity checks. An annual Relative Accuracy Test Audit (RATA) is necessary to maintain certification.

A sorbent trap is an extraction system that directly measures vapor phase mercury emissions. With this method, a grab sample is taken from the stack and pulled onto the sorbent trap. The sorbent captures (“traps”) the mercury in the flue gas while an analyzer will measure the amount of mercury in the sorbent. Calibration gases are not required for operation. However, the traps are typically set up for a seven-day continuous run and therefore must be replaced weekly. Initial and annual RATA verification are also required for certification of this type of system.

For both systems, additional flue gas measurements must be made to ensure accuracy. Oxygen, carbon dioxide, moisture, and gas flow measurements of the unit are needed to support these systems. Although most large combustion sources currently measure these parameters for combustion control and other boiler functions, some smaller units do not measure some of these parameters on a continuous basis.

A special exception is allowed for EGUs that have been determined to qualify as low-emission mercury sources. In these cases, the EGU will only be required to perform periodic, once-a-quarter monitoring of mercury utilizing EPA Test Method 30B. To qualify as a low-emission source and move to periodic monitoring, a unit’s mercury emissions must be less than or equal to 29 pounds per year for at least three years.

Measurement of hydrochloric acid (HCl) for existing units will depend primarily on the current configuration of the unit. If the facility is operating an existing flue gas desulfurization (FGD) system, then the plant’s existing Part 75 CEMS system will suffice for HCl compliance. If no existing FGD system is in place or if the facility is new, then two options may be chosen for HCl monitoring. Either a CEMS system for HCl measurement or quarterly monitoring by EPA Test Method 26/26A may be used.

For the measurement of filterable particulate matter (PM), many more options exist. Typically, either a PM-CEMS or PM–Continuous Parametric Monitoring System (CPMS) is used for measurement of filterable particulate emissions. For units that operate with flue gas temperatures greater than the dew point temperature, several measurement techniques exist. PM emissions may be measured using an optical system that will measure either the opacity or dynamic opacity (scintillation). An alternative technology relies on scattered light that reflects off particles in the flue gas. In this technique, a receiver measures the amount of light scatter from a light source and equates that to a particulate loading. Non-light-based measuring systems are also available that utilize the electrification of a probe to measure PM emissions.

For those units that operate below the dew point limit in the stack, there are still options for PM measurement. These techniques are not in situ. Rather, they require the extraction of flue gas from the stack. Common measurement techniques for extraction methods include beta absorption and extractive light scattering.

Control of Pollutants

Control of these pollutants is just as complex as the measurement techniques (see sidebar). The control of mercury emissions is particularly difficult, as primary control techniques adsorb mercury onto a sorbent, which is then captured by a particulate control device. Mercury, after the combustion process, exists in three states: an elemental state, a particulate state, and a divalent state. Mercury’s state is critical to its mitigation, as mercury in a particulate or divalent form has the greatest potential to be removed from the flue gas stream. Mercury existing in an elemental state is a very stable molecule. It must be forcibly oxidized to promote capture, or else it will typically pass through the boiler and emission control devices.

ACI systems are currently the best-developed technology for mercury reduction. Depending on fuel characteristics (such as the amount of halides present) and combustion characteristics (such as the amount of unburned carbon in fly ash), the proportions of mercury present in a divalent or elemental state in the flue gas will vary. An ACI system must be specifically engineered to meet removal rates required by regulations. This includes varying the porosity of the sorbent or adding halides to aid in the adsorption of mercury. It must also be noted that the addition of activated carbon will affect the quality of the fly ash. This leads to the potential of fly ash no longer being marketable, which has additional economic impacts on a facility.

Hydrogen chloride is a substance that can be removed by several techniques that will break down the acid gas into a neutral substance. Depending on the level of fuel-bound chlorides, calcium-based sorbents such as limestone and hydrated lime have the potential to remove the desired amount of hydrogen chloride. These sorbents are typically used in sulfur dioxide scrubbing systems; however, they can also be injected directly into the furnace. If additional removal rates are required, then sodium-based sorbents such as trona or sodium bicarbonate may be injected from upstream of the economizer to the outlet of the air preheater.

Filterable PM may be a more problematic pollutant to control with a plant’s existing equipment. Removal rates for some facilities will be pushed upward of 99.99%, and the addition of various sorbents for mercury and HCl mitigation will only increase particulate loading. For plants utilizing electrostatic precipitators (ESP), the removal rates required may push this technology beyond its limits. If the existing ESP is unable to handle the removal rates, then options to convert the ESP to a pulse jet fabric filter may be investigated. If this is not a feasible option, then an expensive option of decommissioning the ESP and replacing it with a pulse jet fabric filter would be required.

|

| 2. Remove acid gases. A spray dryer absorber is often installed to control acid gases such as sulfur dioxide and hydrochloric acid. Courtesy: KBR Power & Industrial |

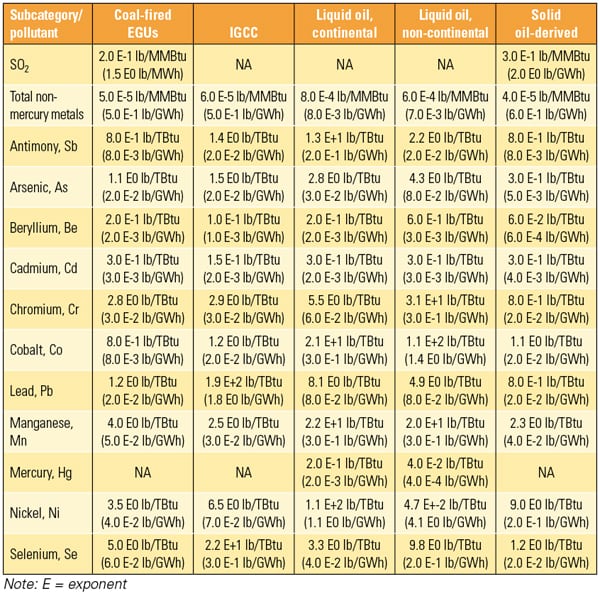

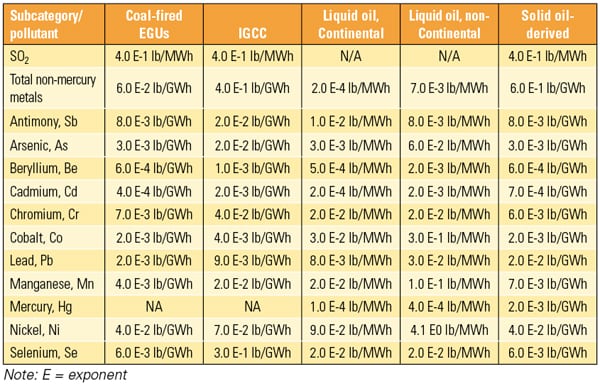

Alternate Emission Limitations

The EPA has developed equivalent emission standards as alternative limitations that a facility may opt to meet. As a substitute for meeting HCl emission levels, for example, the EPA has produced an equivalent emission standard for sulfur dioxide. If a facility cannot meet the filterable PM emission standards, then the EPA has also developed equivalent standards for total non-mercury metals and individual non-mercury metals. Individual non-mercury metals include the following hazardous air pollutants: antimony, arsenic, beryllium, cadmium, chromium, cobalt, lead, manganese, nickel, and selenium.

If a facility were to elect to meet an alternative emission limitation based on total nonmercury metals or individual nonmercury metals, some measurement or baseloaded emission issues may need to be addressed. For new units looking to utilize coal or those that might consider switching fuels, it is common to utilize the EPA’s Compilation of Air Pollutant Emission Factors, or AP-42, to determine emission rates of nonmercury metals. This set of data, published since 1972, has been developed from source test data, material balance studies, and engineering estimates (Tables 3 and 4).

|

| Table 3. Alternate emission limitations for existing EGUs. Source: EPA |

|

| Table 4. Alternate emission limitations for new EGUs. Source: EPA |

In order to meet the prescribed regulations, direct measurement of nonmercury metals will be necessary. EPA Test Method 29 is required to measure either total nonmercury metals or individual nonmercury metals. If direct measurement shows that nonmercury metal emissions are higher than EPA estimation equations, very little can be done to mitigate this problem. Upgrades to filterable particulate control devices will be required to achieve higher efficiency rates that drive down the nonmercury metal emission rates. The result is no more of an economic advantage than if the facility were to have chosen a filterable particulate emission limitation to begin with.

Looking Forward

As the compliance date for the MATS regulation continues to creep closer, facilities using coal, solid oil-derived fuel, or oil must start taking affirmative action to comply. A significant amount of capital investment followed by years of additional operating expenditures will be required to remain operational. Understanding how this affects the future of coal-powered generation is difficult, and multiple plant closures will most likely occur as a result of this regulation.

Confusion is added to the compliance timeline as the EPA issued a stay on the effective dates for new facilities while holding steady on the effective dates of some existing facilities with equivalent emission limitations.

Measurement techniques are extensive and require sensitivity not previously obtainable. Litigation continues, which may further change what has been promulgated. The recent vacating of CSAPR leads to questions about the future of MATS, although how the court rules on the EPA’s petition is anyone’s guess. Further appeals are also possible.

All of these circumstances make it difficult to predict if the final rule is truly “final.” What is certain is that there are no easy off-the-shelf solutions. While the court juggles CSAPR, it is critical for facilities to evaluate their operations and start down the path toward MATS compliance.

— Brandon Bell, PE (brandon.bell@ kbr.com) is a principal mechanical engineer with KBR Power and Industrial, Chicago.