Increase the IQ of Your Intelligent Sootblowing

Power plants have been blowing soot using essentially the same method for decades. However, technological advances now offer boiler operators a much-improved technique. Rather than running sootblowing systems “blind,” a targeted sootblowing system—such as the Sootblower Fouling Detection System—removes guesswork by pinpointing exactly when and where sootblowing is required.

Your cell phone tells you when it needs to be recharged. Many cars pinpoint exactly when service is required. Why not let your power plant boiler do the same? With the help of today’s technology, sootblower operations can be managed with real-time data rather than relying on presumptive common operating practices.

While supplying approximately 30% of the total electricity generation in the U.S. during 2016, coal-fired plants accounted for about 68% of carbon dioxide emissions. At the same time, coal plants ranked among the most costly to build and maintain. Consequently, coal-fired plants are under close scrutiny and constant pressure to reduce emissions, increase output, and operate more efficiently, while lowering capital costs. Needless to say, efficiently running plant equipment plays a significant role in reaching these and other goals. And for coal-fired plants this means keeping boilers in top condition and operating at full capacity.

Boiler cleanliness is one of the keys to operating at peak performance. As a result, boilers generally garner plenty of maintenance attention. At some point, soot will build up on the tubes inside the boiler, taking a toll on performance. This buildup, also known as fouling, requires periodic cleaning via a process known as sootblowing.

There can be certain indications of when boiler tube cleaning is required. For example, a noticeable decline in output or a fan that’s working harder than normal may indicate that soot buildup has reached a critical point. By the time these symptoms arise, however, gains made toward output efficiency and emissions targets have often been sacrificed and cannot be recouped.

Sootblowing Today

In a typical power boiler, fuel is burned inside the furnace, creating hot gases, which heat water in the steam generating tubes. In the case where the fuel is coal, the flue gases often contain a significant amount of carryover. This residue collects on the boiler tubes and builds up over time. The buildup negatively impacts the boiler in multiple ways, such as:

■ Decreasing the efficiency of the heat being transferred to generate steam.

■ Increasing the risk of plugging the boiler.

■ Contributing to high emissions of NOX, SO2, and other harmful emissions.

|

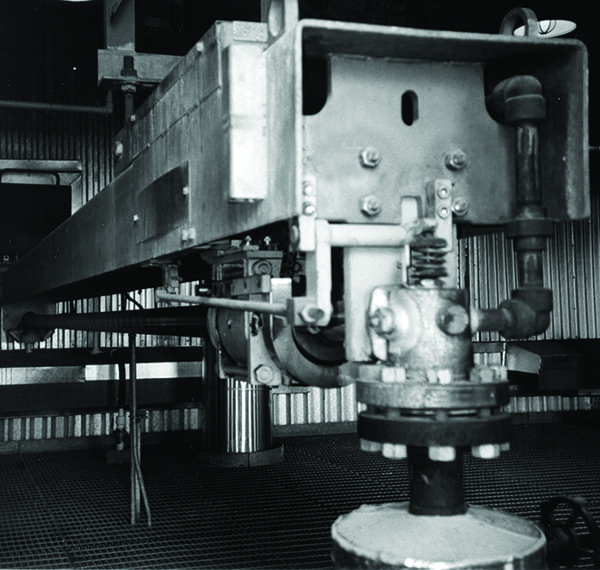

| 1. Sootblowers. Long retractable sootblowers such as the ones shown here are found throughout boiler superheater and reheater sections. Courtesy: Clyde Bergemann |

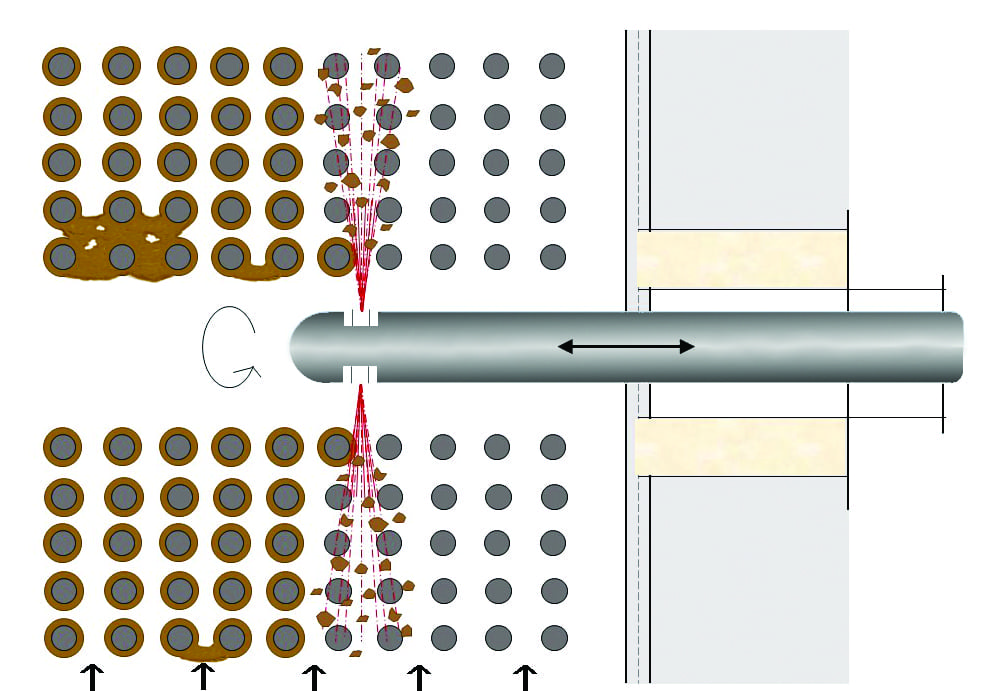

To address these issues, boiler operators utilize sootblowers installed near problematic locations (Figure 1). In sootblowing, rotating lances are inserted horizontally through the boiler wall and into the boiler to remove buildup. These lances expel pressurized steam, water, or air to blast the soot from the boiler tubes (Figure 2). As a result, the process increases costs, both from expenses associated with the cleaning as well as from the power required to drive compressors and pumps. Significant savings can be realized even if only a fraction of the total steam consumed by sootblowing operations is eliminated.

While these costs can certainly add up, the real concerns lie in boiler downtime and equipment damage. Many coal-fired facilities operate via unmanaged sootblowing. Because there’s no real-time indication of when or where buildups are occurring, sootblowing schedules for each individual boiler are determined by common operating practices or regularly scheduled cleaning, or in some cases, best guesses. Cleaning in this manner may ultimately get the job done, but it’s often unnecessary, can negatively impact operations, and can shorten the life of boiler tubes.

So what’s the problem? When you wash your car, you’re not just cleaning the dirty parts, right? In a boiler, the problem is erosion. While blasting boiler tubes with steam does remove soot, it also accelerates erosion, which results in leaks. Excluding, or lightly treating, areas with little or no buildup can extend boiler tube life significantly.

Some problems with traditional sootblowing methods include:

■ Delegating sootblowing to individual operator judgment leads to inconsistent cleaning patterns and requires continuous operator intervention.

■ Waiting for a boiler to show signs of a problem can take the boiler offline for an extended period of time.

■ Treating the entire boiler exposes clean tubes to unneeded treatment, which leads to erosion, which leads to leaks, which leads to shutdowns and extensive maintenance.

Operating essentially blind, boiler operators face a Catch-22 challenge of adequately cleaning without over-cleaning. Recognizing the importance of a clean boiler, many coal-fired power plants have consequently resorted to a regular complete scrub of boiler tubes whether needed or not. When considering the impact that prolonged boiler downtime associated with a thorough cleaning has on production and profitability there is hope for a better way.

Today, technology is removing the scheduling guesswork, over-scheduling, and general inefficiencies from boiler tube cleaning. It can now be determined exactly when sootblowing operations should be performed, and precisely where and to what extent such operations should be directed. The results include no unnecessary downtime, less steam usage, faster cleaning, and extended tube life. And the best part is that the boiler itself is supplying the information.

Targeted Sootblowing

Targeted sootblowing removes the guesswork by pinpointing exactly when and where sootblowing is required. Furthermore, this technology can determine the extent of fouling. Armed with such information, sootblowing operations can thoroughly clean areas where fouling is especially heavy, touch on tubes that require just a quick cleaning, and avoid areas requiring no attention.

One such solution for optimizing boiler-cleaning operations has been developed by Milford, Ohio-based Integrated Test and Measurement (ITM). The technology, known as the Sootblower Fouling Detection System (SFD System), was originally created to direct sootblowing operations in the pulp and paper industry. Pulp and paper recovery boilers burn black liquor, producing a very high concentration of ash. The technology has a track record of success and is now making its way into power generation.

As it measures fouling along the path of a sootblower, the system has two primary purposes:

■ To help understand where fouling is occurring in order to optimize sootblowing.

■ To provide real-time data for control systems, allowing targeted cleaning.

“The results are immediate savings in steam consumption, prevention of tube erosion in areas with little to no buildup, and increased boiler efficiency in areas with significant buildup,” explained ITM President Tim Carlier. “The system continually monitors buildup levels within the boiler in real time, alerting operators when cleaning is required.

“As the sootblower lance enters the boiler, instrumentation on the sootblower delivers feedback to pinpoint where and how much buildup is present. An increase in the amplitude of the sensor indicates buildup, and a consistently low-amplitude response indicates areas where no buildup is found. This allows sootblowing to be applied only to areas in need of cleaning.”

The SFD System interfaces directly with the plant’s distributed control system and is installed without the need to take the boiler out of service. While the sootblower is in operation, sensors continually monitor fouling conditions. As soot builds, the sensors communicate the extent and location of buildup back to the host system. Advanced software algorithms within the SFD System analyze the data and alert plant personnel when and where soot buildup is reaching significant levels.

Head to Head: SFD Versus Traditional Methods

It is worthwhile reviewing how boilers with and without the SFD System respond to areas of low and high buildup along the path of specific lances.

Little to No Buildup. A traditional, unmanaged sootblowing system continues to operate at the same rate, no matter what the level of buildup. However, the system employing SFD technology confirms that there is no significant buildup along the path of this specific sootblower. At this point, this crucial information informs automated controls (or plant operators) to decrease the rate of sootblowing. In the end, the system results in immediate savings with less steam usage, and minimizes long-term tube erosion by not subjecting clean tubes to unnecessary sootblowing.

Significant Buildup. In a scenario where fouling is significant, without the visibility provided by the SFD System, it is unlikely that the traditional “blind” sootblowing process will run the lance often enough—or in the needed locations—to effectively clean the fouled tubes. Without SFD, operators have no way of knowing that an area has a higher degree of buildup, robbing the plant of steam-generating efficiency. Conversely, the SFD System detects the buildup, and immediately adjusts the rate of cleaning through control logic or via manual input by the operator. Going a step further, if the control system is in place, the sootblower lance can target specific fouling locations and focus on cleaning those sections appropriately. These improvements directly result in an increase in efficiency of the superheated steam generation process, providing more power for the entire facility.

SFD Benefits

On its own, the removal of sootblowing guesswork will generate a quick return on investment. Savings are further accelerated through steam savings; elimination of outages; improved heat rate; cleaner, more-efficient burning; and more. When all is said and done, power generation facilities can expect to see a return on investment from the SFD System in approximately six months to a year.

Another benefit is the ability to monitor the condition of the sootblower system itself. This data can provide immediate feedback and answer such questions as:

■ What’s the condition of the sootblower motor and gearbox?

■ Is the poppet valve (Figure 3) stuck open or leaking?

■ Is the track damaged?

■ Is the sootblower lance bent?

■ Is the sootblower stuck in the boiler?

■ Has sootblower packing deteriorated?

■ Are there steam leaks on or near the sootblower?

Additionally, poor boiler performance isn’t always linked to the collection of soot. SFD visibility can immediately eliminate fouling as a suspect, allowing maintenance to concentrate on other areas, so time isn’t wasted on unneeded sootblowing when problems lie elsewhere.

Leveraging Technology

Traditional sootblowing operations are riddled with inconsistencies: under-cleaning, over-cleaning, needless cleaning, wasted steam, and expensive downtime. Like other industries, coal-fired power plants would benefit by embracing the latest technology.

Driven by tools like the SFD System, smart sootblowing provides the information and visibility to remove the guesswork, allowing a more precise and complete attack on fouling. The results are an increase in a plant’s overall efficiency of the boiler’s superheated steam generation process, while mitigating the risks of tube erosion and plugging the boiler.

Furthermore, ITM is offering power plants an opportunity to test the SFD System on a trial basis. The company will install a temporary system, allowing power plants to essentially benchmark SFD against traditional sootblowing operations. “We want to get this technology into the hands of the power generation industry and allow the technology to prove itself,” said Carlier. “We’re confident that once power stations experience its ease of use and benefits the Sootblower Fouling Detection System will become a standard piece of equipment.” ■

—Mark Yeager ([email protected]) is engineer/lead programmer for Integrated Test and Measurement (ITM).