Plant Design

-

Gas

Practical Considerations for Converting Boilers to Burn Gas

Many utilities have taken advantage of relatively low-cost natural gas to address environmental pressures and upgrade their power generation portfolio in one of three distinct ways—replace, repower, or

-

O&M

How Stealth Combustion Losses Lower Plant Efficiency. Part 1: The Problem

At the average coal-fired power plant, the battle to reduce net heat rate is complicated by skin-tight maintenance budgets, staff reductions, and—for some—the switch from baseload to mid-peaking service. The most fruitful approach to improving a plant’s heat rate is to optimize combustion in its boiler, particularly by minimizing the amount of “stealth” air in-leakage.

-

Coal

Leadership Changes at Mississippi Power as Kemper IGCC Cost Overruns Soar

Cost overruns of nearly $1 billion to build the 582-MW Kemper integrated gasification combined cycle (IGCC) plant in Kemper County, Miss., were underscored on May 20 as Mississippi Power’s Board of Directors took the dramatic step of replacing the Southern Co. subsidiary’s leadership.

-

O&M

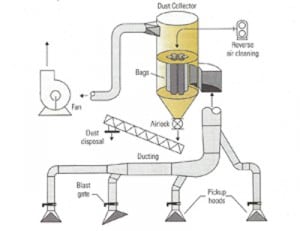

Give Your Plant a Dust Control Tune-Up

Every piece of equipment that transports or processes coal creates some level of particulate matter. Having a strategy for coal dust management in your plant is essential.

-

Coal

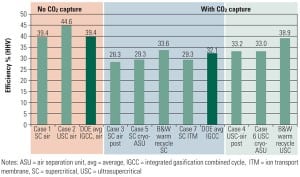

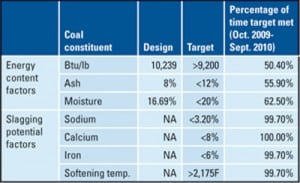

Kemper County IGCC Project Update

The integrated gasification combined cycle (IGCC) plant located in Kemper County, Mississippi, is a 2 x 1 plant that will produce 582 MW at peak and 524 MW fired on syngas, with ammonia, sulfuric acid, and carbon dioxide as by-products. The carbon dioxide will be used for enhanced oil recovery (EOR). Engineering was completed in Q3 2012, and the facility’s commercial operation date is planned for May 2014.

-

Coal

Project Planning Key to Smooth J.T. Deely 2 SCR Retrofit

Recent experience on the Deely 2 SCR retrofit project reminds us that the time spent in thoroughly planning a project prior to the start of construction is usually repaid with avoided construction delays.

-

O&M

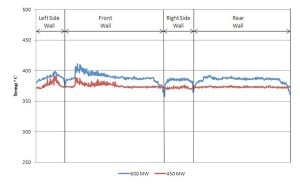

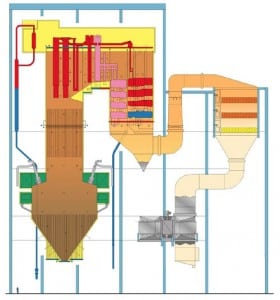

Jinzhushan 3: The World’s First PC-Fired Low Mass Flux Vertical Tube Supercritical Boiler, Part 3

The world’s first supercritical pulverized coal–fired low mass flux vertical tube Benson boiler is Jinzhushan 3, located in the Hunan Province of the People’s Republic of China. The 600-MW Babcock & Wilcox Power Generation Group Inc. once-through boiler burns Chinese anthracite using downshot pulverized coal (PC) technology. Part 1 of this three-part article presented a summary of the project design features. Part 2 discussed the boiler technology. This third and final part reviews the plant’s performance test results.

-

Coal

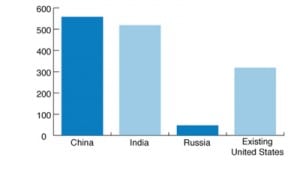

Countries Worldwide Propose to Build 1,200 New Coal Plants

While the war on coal is working to reduce coal generation and consumption and associated carbon dioxide emissions in the United States, many world economies are looking toward coal for future generation needs. China, India, Russia, and Germany, to name a few, are building coal-fired power plants.

-

O&M

EPRI: Generation Sector Research Update

This synopsis of today’s most interesting research related to power generation gives you a glimpse of what’s possibly coming to your plant in the not-so-distance future. Research under way today will surely determine how power plants are designed, operated, and maintained for many years to come.

-

O&M

Insulation and Lagging Fundamentals

Insulation and lagging are key to saving energy in a typical steam plant, and plant operators would be well advised to pay close attention to energy losses in their insulation and lagging systems.

-

O&M

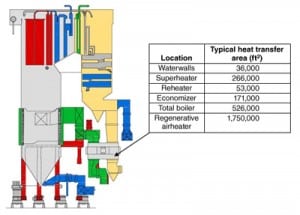

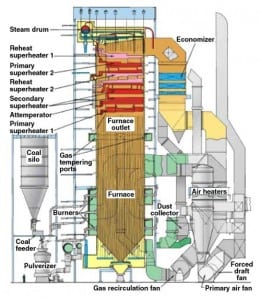

Jinzhushan 3: The World’s First PC-Fired Low Mass Flux Vertical Tube Supercritical Boiler, Part 2

The world’s first supercritical pulverized coal–fired low mass flux vertical tube Benson boiler is Jinzhushan 3, located in Hunan Province of the People’s Republic of China. The 600-MW Babcock & Wilcox Power Generation Group Inc. once-through boiler burns Chinese anthracite using downshot pulverized coal (PC) technology. Part 2 of this three-part article discusses the boiler technology. The third and final part will review the plant’s performance test results.

-

Coal

Jinzhushan 3: The World’s First PC-Fired Low Mass Flux Vertical Tube Supercritical Boiler, Part 1

The world’s first supercritical pulverized coal–fired low mass flux vertical tube Benson boiler is Jinzhushan 3, located in the Hunan Province of the People’s Republic of China. The 600-MW Babcock & Wilcox Power Generation Group Inc. once-through boiler burns Chinese anthracite using downshot pulverized coal (PC) technology. Part 1 of this three-part article provides a project summary and overview. The other two parts will look at technology features of the unique boiler design and plant performance test results.

-

Coal

Coal to Gas Once More for Dominion

Dominion Virginia Power plans to convert its oldest coal-fired power plant, the 227-MW Bremo Power Station near Bremo Bluff, Va., to natural gas, the company announced earlier this month. The two-unit plant would be the ninth in its fleet to be closed or converted to alternative fuels.

-

Coal

Design Features of Advanced Ultrasupercritical Plants, Part III

Advanced ultrasupercritical (A-USC) is a term used to designate a coal-fired power plant design with the inlet steam temperature to the turbine at 700C to 760C. In the first two parts of this three-part report, we introduced the A-USC boiler and the metallurgical advancements required for the A-USC boiler to operate at such high temperatures. This final report explores the A-USC boiler’s unique design challenges.

-

Coal

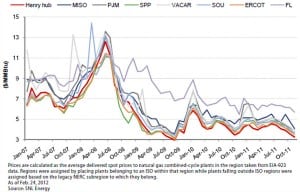

Coal-to-Gas Switching: It’s All in the Price

Trying to assess the potential for coal-to-gas switching in today’s environment is something of an art form. Suppose for a moment that one were able to devise an economic model that truly replicates real-world generation dispatch for plant operators. A model is only as good as the inputs that go into it, and, let’s face it, future natural gas prices are a critical component.

-

O&M

Optimizing Your Coal Ash Recovery Operation

Coal combustion products often can be recycled into a variety of construction and building materials. However, first you must be able to retrieve the wet ash from a holding pond before the ash can be dried and sold.

-

Coal

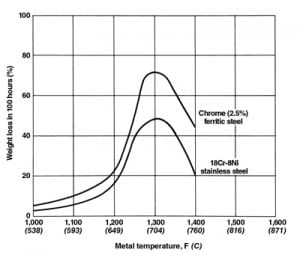

Design Features of Advanced Ultrasupercritical Plants, Part II

Advanced ultrasupercritical (A-USC) is a term used to designate a coal-fired power plant design with the inlet steam temperature to the turbine at 700C to 760C. In Part I of this three-part report, we introduced the A-USC boiler. In this segment, we look at the metallurgical advancements required for the A-USC boiler to operate at such high temperatures. The final report will explore the A-USC boiler’s unique design challenges.

-

Coal

Design Features of Advanced Ultrasupercritical Plants, Part I

Advanced ultrasupercritical (A-USC) is a term used to designate a coal-fired power plant design with the inlet steam temperature to the turbine at 700C to 760C. In Part I of a three-part report, we introduce the A-USC boiler. Future reports will discuss the metallurgical and boiler design challenges.

-

O&M

Constructing and Managing Coal Ash Landfills

Creating a landfill to hold dry boiler ash is a challenging proposition these days. There’s more to the project than you might imagine, as you’ll learn from this article about the development of a typical new ash landfill.

-

O&M

Wet Booster Fans Optimize Power Station Performance with FGD and Wet Stack

A Romanian lignite-fired power station wanted to minimize the operating cost of the flue gas desulfurization (FGD) system by placing the booster fans in the "wet position," between the wet FGD scrubber and the wet stack, where they would consume significantly less power. A number of combined environmental effects must be considered in this design.

-

O&M

Improved Performance from Priority-Based Intelligent Sootblower Systems

When sootblower operation frequency is too high, a plant risks losing power generation from tube leaks; but when sootblower frequency is too low, there is a risk of boiler pluggage. Intelligent sootblowing finds the right balance between tube erosion and plant economic operation.

-

O&M

Enhanced Capture of Mercury Using Unique Baghouse Filter Media

Several states have already instituted mercury emission limits in expectation of tightening mercury emission rules that will require reductions of up to 91%. Coal-fired plants searching for an economical way to meet the new limits may need to look no further than replacing their baghouse filter elements.

-

O&M

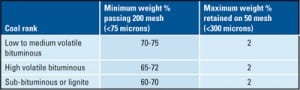

Pulverizers 101: Part II

Pulverizers prepare the raw fuel by grinding it to a desired fineness and mixing it with the just the right amount of air before sending the mixture to boiler burners for combustion. In Part I of this three-part report, we examined the essentials of pulverizer design and performance. In the second part, we discuss the importance of fuel fineness. In the final article, we will discuss the importance of air and fuel measurement.

-

O&M

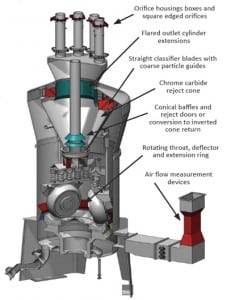

Improved Coal Fineness Improves Performance, Reduces Emissions

Utilizing engineering ingenuity and today’s developing computational fluid dynamics tools, a new classifier design is now available that significantly improves fineness from pulverizers without the heavy costs associated with dynamic classification or any downsides on pulverizer capacities, maintenance, and parasitic power. Instead, operational flexibility and improved emission control options are enhanced.

-

Coal

Innovations in Air Heater Design Produce Performance and Reliability Improvements

The regenerative air heater on a typical steam generator usually accounts for over 10% of a coal-fired plant’s thermal efficiency. A poorly performing air heater will cause an increase in the gas outlet temperature, often reducing the electrostatic precipitator collection efficiency and baghouse reliability. Recent design innovations enable restoration of this lost performance.

-

O&M

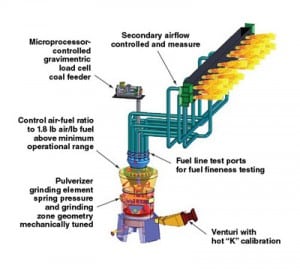

Pulverizers 101: Part I

Pulverizers prepare raw fuel by grinding it to a desired fineness and mixing it with the just the right amount of air before sending the mixture to boiler burners for combustion. In Part I of three parts, we’ll examine the essentials of pulverizer capacity, what should be done after a coal pulverizer fire or other incident, and how to tune up pulverizer performance. In future articles we’ll discuss measuring pulverizer performance and performance optimization.

-

O&M

Natural Gas Conversions of Existing Coal-Fired Boilers

Why should utilities consider converting existing coal-fired plants to burn gas? We explore the rationale for fuel switching, some of the options available for the conversion of coal-fired units, technical considerations related to conversion, and some of the financial considerations that will impact the final decision.

-

O&M

Applying CFD to Optimize Furnaces Cofiring Biomass, and the Impact of Cofiring on SCR

The international policy framework regulating the emissions of greenhouse gases from industrial and utility boilers is in flux. Meanwhile, most boiler owners are evaluating potential strategies for when, not if, more stringent emissions reduction regulations are put in place. One of the most attractive compliance options is the cofiring of biomass in existing coal-fired boilers.

-

Coal

Biomass Boiler Market Remains Unpredictable

Utilities struggling to meet renewable portfolio standards requirements have studied the conversion of existing coal-fired boilers to burn biomass. The results of those studies have been mixed, although test burns continue; the results of one such test are included. Overall, the market is tending toward smaller biomass projects, and the low price of natural gas is perhaps the biggest reason utility-scale projects are now few and far between.

-

Coal

Duke, Progress Energy Merging into Biggest U.S. Power Utility

Duke Energy and Progress Energy announced January 10 that they are combining to create the nation’s biggest electric utility. The $13.7 billion deal is likely to draw tough scrutiny from federal and state regulators—and some protests from big power buyers—given the companies’ overwhelming market dominance in North Carolina and more modest operational overlap in South Carolina.