O&M

-

Partner Content

Case Study: Exelon Ensures Nuclear Power Plant Safety Using Online Monitoring

Exelon has optimized the efficiency of its operations, maintenance, and engineering staff. By automating data collection, plant engineers now focus on analyzing data rather than manually collecting data and risking radiation exposure. Download this case study to get more details then go here to learn more about Condition Based Maintenance (CBM) for Power Generation.

-

O&M

Winning the Cooling Tower Trifecta: Controlling Corrosion, Scale, and Microbiological Fouling

There is a synergistic relationship among the three major cooling water treatment issues: corrosion, scale or deposit formation, and microbiological fouling. In order to control one, you need to control all

-

O&M

Leveraging Fuel Flexibility for Coal Power Plant Survival

While having lunch at a downtown café with my friend the biology professor, the subject of animal extinction arose. “When it comes down to it, we really don’t know exactly why most prehistoric species

-

O&M

Optimize Power Plant Operations with Industrial Data Management and Predictive Analytics

In today’s digital world, an optimally run power plant relies on valuable and accurate data in order to ensure assets are running reliably and with minimal downtime. Streaming in from control systems, SCADA

-

Partner Content

Condition-Based Maintenance Bolsters the Bottom Line in Power Generation

The power generation industry is undergoing a period of rapid transformation. A growing number of operators are considering the adoption of condition-based maintenance (CBM). This whitepaper discusses the forces that are driving demand for CBM, how CBM works and why it is an effective alternative to planned maintenance strategies.

Find out more about CBM for Power -

O&M

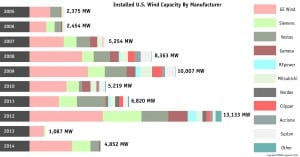

DOE Report Highlights Triumph, Trouble for Wind Power Sector

U.S. wind power is becoming more widespread and costs are generally on the decline, but the sector is troubled by policy uncertainties, a new report from the Energy Department says. After a lackluster year in 2013, wind power capacity additions in the U.S. rebounded nearly 8% in 2014, driven by recent improvements in the […]

-

O&M

Making Sense of New Arc Flash Protection Rules

Standards and regulations may change, but the danger associated with arc flash hazards remains. Analyzing potential incident energy correctly and understanding what personal protection equipment is required can help workers stay safe and avoid painful, or even life-threatening, injuries. The Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) have both […]

-

O&M

Electrical Arc Flash Protection Solutions

I’ve got some good news and some bad news. The good news is that, according to the U.S. Bureau of Labor Statistics, the number of occupational fatalities resulting from exposure to electricity has decreased steadily during the past 10 years (Figure 1). The bad news is that 141 people died on the job in the […]

-

O&M

Grooved Mechanical Piping Offers a Versatile Pipe-Joining Alternative

Two of the most important elements in any construction or upgrade project are safety and speed of completion. While one way to increase safety is to eliminate hot work whenever possible, the reality is that welding is necessary for many tasks around a power plant. However, one area where welding may not always be required […]

-

O&M

New Renewable Projects Face Old Safety Hazards

Many of the dangers existing at conventional power plants also threaten personnel in the wind and solar energy sectors. All workers can benefit by reviewing lessons learned and implementing corrective actions to improve health and safety performance. The expanding wind and solar energy sectors are not immune to industrial hazards affecting all energy generation markets. […]

-

O&M

Ignalina: Decommissioning Chernobyl’s Big Sister

This is a web supplement to “Riding Off into the Sunset: Nuclear Decontamination and Decommissioning Update,” appearing in the July 2015 issue of POWER. The Ignalina Nuclear Power Plant (INPP) is located in eastern Lithuania near Visaginas—a town of more than 20,000 people founded in the mid-1970s for workers constructing INPP and for the […]

-

O&M

Metallurgical Aspects of Secondary Combustion on Boiler Pressure Parts

Controlling combustion in fossil fuel power plants in order to control the emission of pollutants sometimes has adverse effects on plant equipment, including certain metals. To understand how to address the problem, it helps to understand how it develops. The emission of nitrogen oxides, generally referenced as NOx (NO or NO2), has several adverse effects […]

-

O&M

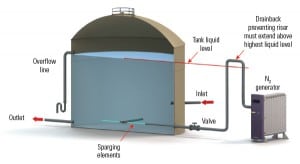

Prevent Contamination and Corrosion in Demineralized Water Storage Tanks Using Nitrogen Sparging and Blanketing

The electric power generation industry relies heavily on demineralized and deionized water during process operations. Managing the water supply is critical not only under normal operating conditions, but also during outages. When scheduled or unscheduled outages occur, many boiler and pre-boiler systems are drained. After the outage, they are refilled with water that has been […]

-

O&M

Continuous Water Washing in Wet Electrostatic Precipitators Reduces Capital Cost in the Chinese Market

As the Chinese government lowers the particulate matter (PM2.5) limits to 5 mg/Nm3 or less in coal-fired power plants, wet electrostatic precipitators are one of the key environmental components utilities select to meet this requirement. Optimization of continuous water washing of electrodes allows lower-cost alloys to be used, reducing capital expenditures. Wet electrostatic precipitators (WESPs) […]

-

O&M

Optical Gas Imaging Camera Offers Hydrogen Leak Detection Solution

The operation of an electric power generator produces large amounts of heat that must be removed to maintain efficiency. Depending on the rated capacity of the generator, it might be air-cooled

-

O&M

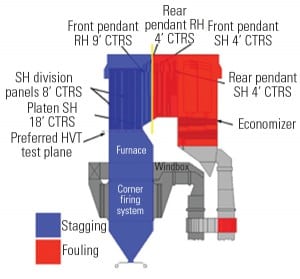

Typical Causes of Slagging and Fouling Problems in Boilers

Boiler slagging and fouling, and the resulting frequent operation of sootblowers, are some of the major operations and maintenance factors that can negatively affect power plant reliability and efficiency. Boiler slagging and fouling are among the most common causes of maintenance headaches at coal-fired power plants. Though you cannot totally eliminate the problem, following proper […]

-

O&M

CO2 Blasting Restores HRSG Performance

Steam production is strongly influenced by the cleanliness of the gas-side heat transfer surface in a heat recovery steam generator (HRSG). However, when deposits begin to impede heat transfer or increase gas-side pressure drop, it is time for a cleaning. CO2 pellet blasting is a cost-effective and environmentally benign cleaning method available to power plant […]

-

O&M

Innovative Wind Turbine Blade Inspection and Maintenance Tools

The life of a wind turbine can be pretty precarious. The blades—made of laminated materials, such as composites, balsa wood, carbon fiber, and fiberglass—can reach speeds up to 180 miles per hour at the tip, which means even small particles in the air can cause damage to the surfaces. It’s probably no surprise that lightning […]

-

O&M

Underground Piping: Out of Sight, Out of Mind, Until It Leaks

When many older plants were built, steel and cast iron piping were common materials used underground. Although these materials have proven to have long, useful lives, improvements in plastics offer additional alternatives today. An understanding of best practices for inspecting and servicing buried piping will help you keep systems operating as designed. Most, if not […]

-

O&M

Best Practices for Maximizing Condenser Efficiency

Sometimes overlooked and underappreciated, a power plant condenser can make or break your efficiency and power delivery goals. Understanding how important a role your condenser plays is a good step toward greater heat rate awareness. As part of a university class on power generation systems that I teach, I show my students a Sankey diagram […]

-

Legal & Regulatory

Expert: OSHA’s Arc Flash Final Rule Will Save Lives

For Samy Faried, an ABB expert who has spent 15 years analyzing arc flash hazards, a new rule recently finalized by the Occupational Safety and Health Administration (OSHA) will save lives. In April 2014, OSHA published its Final Rule for Electric Power Generation, Transmission and Distribution Standards (29 CFR 1910.269 and 1926 Subpart V), which […]

-

O&M

Balancing Risk, Reliability, and Safety at Plants Slated for Retirement

When the decision is made to retire a power plant, the work of getting there is just beginning. Maintaining safe and reliable generation requires strong leadership, clear communications, and heightened attention to operations and maintenance, staff morale, and post-shutdown plans. For utilities and other generators facing the challenge of winding down operations at an […]

-

O&M

Understanding Electrical Fire Hazards at Electric Generating Stations

Minimizing the impact of electrical fires in power plants requires a combination of prevention, compartmentalization, detection, and suppression strategies. But first, everyone in a plant needs to understand the hazard. Fires at electric generating stations are rare—but not as rare as one might think. Loss history at hydroelectric facilities, for example, shows that fires involving […]

-

O&M

Innovative Pipe Conveyors: Effective, Efficient, and Environmentally Friendly

Transporting household and industrial waste as well as sewage sludge from a treatment plant to a power station can be a messy business. The utility company Linz AG found that a pipe conveyor system offered an optimal solution. The conveyor is not only highly energy efficient, but due to its closed design, it also allows […]

-

O&M

Doing More with Less: New Solutions Help Address Power Plant O&M Staffing Difficulties

Studies and surveys have predicted a future shortage of skilled workers in the power industry for many years. Unfortunately, the future is here. When qualified workers are difficult to locate, some companies are finding that technology and service contracts allow them to do more with less. It’s no secret that the traditional power industry workforce […]

-

O&M

Wind Power Projects Must Be Managed as Electrical Generation Plants

Wind turbine blades, gearboxes, and generators get most of the attention both within and beyond the power industry. The focus is often on increased capacity and blade lengths, as well as drive train premature failures. That’s natural, because those rotating blades are the most visible part of a wind project. However, successful operation of a […]

-

O&M

Keeping Pollution Control Devices Online with Good Operating Practices

In order to comply with the Clean Air Act and subsequent regulations covering emissions, coal-fired utilities have installed multiple pollution control devices. Understanding key operating aspects of this equipment can help you avoid costly maintenance activities and forced shutdowns. Since the passage of the Clean Air Act in 1970, the regulatory environment for control of […]

-

O&M

Advanced Bearing Technology Eliminates Subsynchronous Steam Turbine Vibrations

A facility’s steam turbine ranks at, or at least near, the top of the list of vital power plant equipment. Without it, the thermal energy in pressurized steam can not be converted to rotary motion, which is

-

O&M

Palo Verde Nuclear Station Sets U.S. Production Record

It’s no surprise that the Palo Verde Nuclear Generating Station led the nation in electrical generation in 2014—it has done that for 23 consecutive years—but with a total output of 32.3 million MWh, it even bested its own previous record set in 2012. The Palo Verde plant is located about 45 miles west of Phoenix, […]

-

O&M

Robotic Inspections of Nuclear Power Plant Storage Tanks

Nuclear power station water storage tanks, located above ground or underground, are constructed of aluminum, stainless steel, or carbon steel. All have naturally occurring electro-chemical processes that can eventually deteriorate the metal, resulting in leaks. Defects that develop on the underside of tank floors are particularly difficult to detect and measure. The Nuclear Energy Institute […]