Automating Control of Work: What Power and Utilities Leaders Need to Know

Control of work, or CoW, processes have a long heritage in the power and utilities sector, acting as an extension to an organization’s existing process safety management approaches. And these processes—which include permit to work, job hazard analysis, and isolation management—are invaluable to environmental, health, and safety (EHS), and operations teams.

These processes ensure work is carried out safely and efficiently. Over the past few years, changing mindsets among power and utilities leaders, along with factors such as the COVID-19 pandemic, have moved CoW into the digital world.

As organizations within the power and utilities sector strive for greater safety and efficiency, digital solutions, including CoW, will become increasingly important, especially amid cultural pressure to become more environmentally sustainable through alternative energy sources, such as wind farms and solar power. Although some power companies are modernizing their plants to become more sustainable, it is still critical for them to derive value from aging assets, including coal- and gas-fired power plants, and this can be accomplished with CoW software.

Executive CoW Perspectives

To get an in-depth understanding of the use and benefits of CoW processes and software, Enablon, a Wolters Kluwer business, recently commissioned independent research firm Verdantix to conduct an interview-based study of 100 executives across different job functions, industries, countries, and risk levels. These findings reveal key trends that can guide leaders who are considering taking their CoW into the digital realm.

|

|

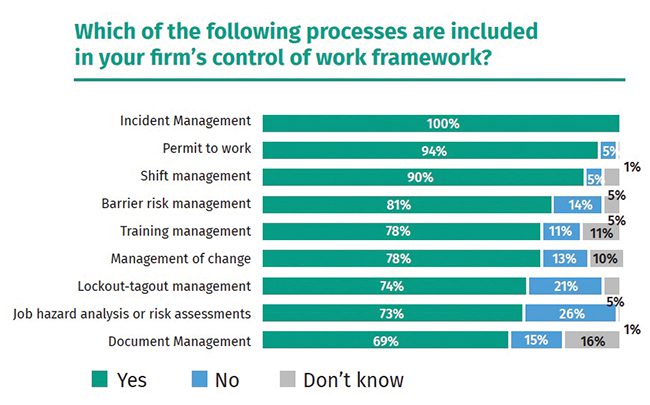

1. A survey, conducted for Enablon by Verdantix, shows that executives are concerned most about incident management when it comes to processes around control of work. Proactively preventing incidents and mitigating their effects is an important part of overall operational risk management. Courtesy: Enablon / Verdantix |

Figure 1 shows the biggest takeaways from the survey and what they mean for the power and utilities industry. They include that incident management, permit to work, and shift management have emerged as integral processes within CoW.

Incident Management. Incident management is the process of proactively preventing incidents, mitigating the effects of incidents, and following up with incidents through investigations and reports. It’s a core part of the mission for EHS and one of the first processes that all organizations adopt to react to incidents when they happen.

Over the past several years, firms have evolved in their approaches toward incident management, from being mainly compliance-focused to including it in the larger context of operational risk management. This explains why 100% of respondents mentioned including incident management in their firm’s CoW framework. These findings reveal that organizations, including those in the power and utilities sector, have been leveraging CoW already without being aware that it was, in fact, CoW.

|

|

2. Utilities and other industrial businesses have been moving from paper to the digital world when it comes to issuing work permits. This has improved efficiency, and has enabled workers to be contacted in the field to complete important maintenance, rather than having to receive work orders at an office location. Source: Shutterstock |

Permit to Work. The process of creating, managing, and approving work permits (Figure 2) is an integral part of CoW. Therefore, it is not surprising that 94% of the EHS, operations, and engineering respondents mentioned including permit to work as part of their CoW framework. While it’s evident that permit to work processing is paramount to these firms, the way in which they carry out these processes can vary, especially within power and utilities.

|

|

3. Digitizing work orders does require investments in both the solution and process improvements, but those investments can be quickly recaptured as they provide cost savings across a utility’s operations. Source: Shutterstock |

One of the biggest challenges firms in this sector are currently facing is the transition from paper permits to digital permit to work (PTW) systems. On one hand, the paper permit to work process can lead to serious accidents in the plant because it’s prone to human errors and doesn’t provide contextual data about the actual state of the plant and people. On the other hand, moving to a digital system (Figure 3) requires investments both in the solution as well as in process improvement. However, with the savings realized from improvements to processes and safety (including a reduction in incidents) outweighing the cost of a digital system, industry leaders are quickly embracing digital PTW processes in their operations.

Shift Management. In the power and utilities industry, we know that energy must be delivered 24/7, and therefore, employees must work around the clock. Tasks and responsibilities need to be effectively transferred from shift to shift, day in and day out.

When the ownership of critical processes isn’t communicated properly, important hazards can go unchecked and escalate into incidents. With the increase in remote work, as well as having to operate with a limited workforce due to COVID-19, controls to manage safety practices between work shifts have further risen on the agenda for industrial firms. Ninety percent of the survey respondents said that they include shift management processes as part of their CoW framework.

Software Essential for Success of CoW Processes

As more companies—including those in the power and utilities industry—place greater importance on getting work done safely and efficiently, there has been an increase in the uptake of CoW software. That’s because CoW frameworks for industrial firms have expanded beyond traditional permit to work and job hazard analysis to include incident management, shift management, and even barrier risk management. This has led to more cross-functional collaboration and stakeholder engagement from operations, EHS, and engineering.

In the survey, 84% of respondents said they view software as either essential or valuable for the success of their CoW processes. While this percentage is significant, it will continue to grow in the future. As more operations teams recognize and find ways to adopt CoW software into their work, more businesses will recognize its value.

One industry where this is already occurring is power and utilities. By adopting CoW software, firms can unlock value in their operational workflow by reducing asset downtime and increasing workforce utilization. From an incident management perspective, CoW software gives power and utilities leaders visibility into the complexities and hazards across a worksite—and even across every worksite in the organization—and the flexibility to drill down into specific areas and address local issues. This is critical because power plants need regular maintenance but are often big and spread out over long distances.

CoW software also enables power and utilities leaders to bypass the challenges of traditional pen and paper, such as managing historical records; getting paper permits printed, signed, and approved; and replacing missing permits.

|

|

4. Control of work (CoW) software digitizes the shift handover process and provides support for workers in the field, which has been particularly important during the pandemic. Workers at a job site can receive needed materials without having to visit an office. Source: Shutterstock |

Finally, CoW software digitizes the shift handover process, ensuring that stakeholders can access and review shift handover reports from any location (Figure 4), which is critical with remote work during the pandemic. By capturing audit trails to ensure supervisors with back-to-back shifts have discussed handovers, CoW software ultimately helps reduce accidents and keeps workers safe.

Improve and Optimize Maintenance Programs

The power and utilities industry always has been focused on general maintenance at power plants. Companies are struggling to perform and manage better. While many are transitioning to more sustainable energy sources and implementing CoW processes at these new sites, there will still be an emphasis on deriving value from aging assets. One way to accomplish this is to improve and optimize maintenance programs through a streamlined CoW process; and that can be done through software.

The idea that a company needs software to improve a process is certainly not new. Software has the power to help transform companies. In this regard, CoW software has been shown to directly influence safety culture. This is especially essential in industries like power and utilities. Many workers are out in the field using their hands to perform their tasks. They’re doing dangerous work every day. CoW software enables these workers to participate and have a clear role in a formal, digital, and streamlined CoW procedure. It also empowers them to contribute to a culture that values safety as much as efficiency.

—Tina Amirtha is senior technology product manager at Wolters Kluwer / Enablon, a group that utilizes software solutions to help companies manage safety and environmental performance, ensure compliance, minimize risks, and improve profitability by leveraging some of the world’s most advanced technologies.