-

Solar

Bavaria Solarpark, Germany

The world’s largest solar electric system was dedicated in June 2005 in Mühlhausen, Germany. The 10-MW system comprises three separate but interconnected photovoltaic parks in different cities that use an innovative sun-tracking system to maximize their outputs. After one year of operation, all three parks are still going strong—as you’d expect, due to their dearth of moving parts.

-

Coal

Bethlehem Energy Center, Glenmont, New York

A great location, a fish-friendly cooling system, and the extent of environmental remediation needed to permit it distinguish this repowering project on the Hudson River just south of the New York State capital.

-

Gas

Brooklyn Navy Yard Cogeneration Facility, Brooklyn, New York

The Brooklyn Navy Yard Cogeneration facility supplies critical electricity and steam to New York City. Situated on an historic site, the plant has earned a series of awards and was the first cogeneration plant to be accepted into both the U.S. EPA National Environmental Performance Track and OSHA’s Voluntary Protection Program in 2005. Through Delta Power’s unique asset management approach that brings added value to projects, BNYC has reinvented itself from a struggling, prematurely aging facility into one of the nation’s leading plants.

-

Coal

Currant Creek Power Plant, Mona, Utah

Commercial operation of PacifiCorp’s first new power plant in more than 20 years coincided with the company’s acquisition by MidAmerican Energy Holdings Company this past March. Currant Creek treads lightly on the environment, provides needed power to PacifiCorp’s eastern control area, and has demonstrated its commitment to be a good corporate citizen of the local community. By any account, Currant Creek is a model for how to develop a power project.

-

Hydro

Kannagawa Hydropower Plant, Japan

With the commercial debut of the first of six planned 470-MW turbines in December 2005, the time has come to pay homage to the sheer size (2,820 MW) and longevity (13 years and counting) of TEPCO’s Kannagawa Hydropower Plant. By the time Unit 2 is commissioned in 2010, and Units 3 through 6 go on-line "in and after 2016," two generations of engineers, technicians, and builders will have worked on the "pure" pumped-storage project since its inception. As if those stats weren’t impressive enough, Kannagawa marks the debut of "splitter runners" for pump-turbines. They increase the effective head of the plant to the highest in the world: 2,142 feet, at a flow of 135,000 gallons/second. That’s a very large pump-turbine, indeed.

-

Gas

Linden Generating Station, Linden, New Jersey

It would be easy to dismiss Linden—which is powered by now-ubiquitous GE 7FA gas turbines and D11 steam turbines—as just another cookie-cutter combined-cycle plant. But its size (1,240 MW), key location near New York City, and use of reclaimed water for all cooling water needs makes Linden deserving of recognition as one of POWER’s Top Plants of 2006. Perhaps its most interesting story is how the project survived more than five years from groundbreaking to commissioning.

-

Coal

Monticello Steam Electric Station, Mount Pleasant, Texas

Why does Monticello, a 30-year-old plant, deserve recognition as one of POWER’s Top Plants of 2006? Because TXU has been blending Powder River Basin (PRB) coal with local lignite at the plant for the past decade, and steady reductions in air-pollutant emission rates have been the result. That positive experience has made the company confident enough to propose building nearly 9,100 MW of new coal- or lignite-fired capacity in Texas by 2010 at a cost of $10 billion. Read on to share some of the lessons that TXU has learned about handling PRB coal safely.

-

News

Banana republic

Learning theorists tell us that one of the key reasons we don’t learn from our mistakes is that we don’t or won’t recognize them as such. We attribute good outcomes to our skill and intelligence and blame bad ones on others or on just plain bad luck. This unhealthy mind-set can be tolerated for […]

-

Gas

Mountainview Power Plant, Redlands, California

Southern California Edison and Bechtel resurrected the 1,054-MW Mountainview power project after a two-year hiatus while meeting aggressive budget and schedule constraints. Edison exercised its option to purchase the project after regulatory approvals were received at light speed, and construction resumed the very day approval was granted. Residents of California’s Inland Empire will enjoy their air conditioners this summer because Mountainview was transformed from a wasteland into a productive plant.

-

Gas

Global Monitor (July/August 2006)

Russia’s new nuclear navy;Russia’s old nuclear navy; First LMS100 fired up by Basin Electric;More Jenbacher gensets to Hungary; A baseload-size wind farm?; EEI bestows Edison Awards; POWERnotes

-

Gas

NYPA Astoria Project, Astoria, New York

New York City has an insatiable appetite for power, but supplying that power from plants inside the city’s five boroughs (where 80% of its peak demand must come from) is tough. So it’s nothing short of miraculous that a 500-MW combined-cycle plant in Astoria, Queens, began commercial operation at the end of 2005. What did it take to bring this plant on-line? The largest state-owned power organization in the U.S.—The New York Power Authority.

-

O&M

Profiling your plant engineering staff

The latest benchmarking study by the EUCG examines the engineering and technical staffing of 62 plants, 92% of which burn coal. If you benchmark your units, plants, or fleet, the results may raise some eyebrows. But they also may help justify your plea for more intellectual capital during the upcoming budgeting cycle. Though the detailed results of the study are proprietary to EUCG member companies that participated in it, POWER was given access to the complete findings. If you want details at the plant/unit level, you’ll have to join the EUCG and participate in the study, which is ongoing.

-

Solar

Saguaro Solar Power Plant, Red Rock, Arizona

We tend to forget that today’s super-sized power plant designs began life as small prototypes that grew in size only as fast as technology and economics allowed. Arizona Public Service, a long-time leader in solar energy development, has invested in the development of one such technology that is compatible with the sunny Southwest and certain to become more cost-competitive in the near future. This successful demonstration of a 1-MW concentrated solar power, trough-style energy system is the first to have put power on the grid since 1988. But it certainly won’t be the last.

-

Nuclear

ISA/EPRI conference offers a smorgasbord of control cuisines

This year’s main course, as usual, was instrumentation and controls. Side dishes of digital nuclear plant controls, plant controller and IT security, corrosion monitoring, and model predictive control added their own distinctive flavors. There was something for every taste, from the theoretical to the practical.

-

Waste to Energy

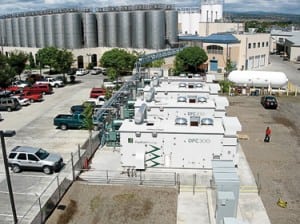

1-MW fuel cell cogeneration project, Sierra Nevada Brewing Co., Chico, California

Beer drinkers know and love Sierra Nevada Brewing Co.’s dedication to bottling premium beers, and that commitment has earned it numerous tasting awards. But it would also win awards on the basis of using clean, high-tech brewing technologies. Sierra Nevada has chosen to minimize its environment footprint by investing in a reuse/reduce/recycle beer-making process. The company has found a way to make its "closed-cycle brewery" a good corporate citizen without compromising bottom-line results.

-

Coal

Globalization: The new millennium’s "invisible hand"

Participants in the CEO Roundtable at Electric Power 2006 raised a plethora of issues affecting decisions on future electric power generation. Representing a cross section of power producers, the industry leaders made clear that, although globalization has lost its luster in the power generation sector, its impact on the domestic industry remains profound. Ten years […]

-

Coal

Safety still Job No. 1 for PRB users

If coal is to be “America’s energy future” (see p. 42), the work of the Powder River Basin Coal Users’ Group (PRBCUG) will have a lot to do with making it so. Since 1999, the PRBCUG (see sidebar) has fostered the safe, efficient, and cost-effective use of the fuel as it watched its membership swell […]

-

Synfuel

Combined Cycle Users’ Group completes another successful year

The third annual meeting of the Combined Cycle Users’ Group (CCUG) was held May 2–4 in Atlanta at Electric Power 2006, in cooperation with the ASME Power Division Combined Cycles Committee and other industry groups. The CCUG’s leadership (Figure 1) drives the group to address issues involving the major components of a combined-cycle plant and […]

-

O&M

Improving the reliability of turbine lube oil supply

Five years ago, San Onofre Nuclear Generating Station’s Unit 3 turbine experienced substantial damage after the supply of oil to its bearings failed. Because the turbine coasted down without oil after it tripped, its bearings, journals, and steam path needed extensive repairs. A follow-up investigation revealed lube oil system vulnerabilities that were subsequently corrected. The lessons learned might also improve your turbine-generators’ lube oil reliability, saving you many millions in lost revenues.

-

Business

Gencos embrace benchmarking as strategic tool

Today’s utility business models re-emphasize utilities’ traditional mission—producing and delivering reliable, affordable power. Tracking how well that mission is executed is the raison d’être of modern plant performance benchmarking.

-

O&M

Computer-based hydro plant scheduling

Hydroelectric power plant managers face unique scheduling challenges. They have a finite amount of water in their reservoirs available for energy production, and they need to schedule generation according to market demand to maximize profits from their limited “fuel” supply. Hydro power plants are capable of producing products other than electricity. Among them are ancillary […]

-

O&M

Monitor your fluid levels online

Although fluid monitoring technology has come of age in recent years, its level of sophistication varies widely across industries. Some users of bulk chemicals, fuels, and other fluids use state-of-the-art systems with bells and whistles like automated data gathering and transmission. At the other extreme, some tank farms still “stick the tanks.” Although 95% of large […]

-

Backroom deals

Richard Nixon was the master of the “big lie” in politics. Once, when his cronies expressed concern about some “liberal” statements he had made, he told them to “ignore what I say and watch what I do.” That insight into an elected representative’s true state of mind is as useful today as it was a […]

-

O&M

Standardizing PdM, fleetwide

The pressure on power producers to supply reliable electricity is unyielding. Forced outages, which usually are caused by unexpected component failure or systemic problems, can prove very costly to both bottom line and reputation. To reduce the frequency and duration of unscheduled outages, many gencos are implementing comprehensive predictive maintenance (PdM) programs. Such is the […]

-

Business

World-class teaching lab prepares next generation of plant operators

The Williamson Free School of Mechanical Trades near Philadelphia has been training power plant operations professionals for 112 years, and its graduates hold top positions at many major gencos, refineries, equipment suppliers, and design and construction companies. Testimonials indicate that it provides one of the best models for training tomorrow’s plant operators.

-

Coal

Coal: The cornerstone of America’s energy future

In April 2005, U.S. Secretary of Energy Samuel W. Bodman asked the National Coal Council to develop a “report identifying the challenges and opportunities of more fully exploring our domestic coal resources to meet the nation’s future energy needs.” The council has responded with eight specific recommendations for developing and implementing advanced coal processing and combustion technologies to satisfy our unquenchable thirst for energy.

-

O&M

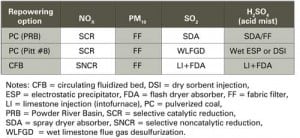

Project Planning: Repowering or Replacement: What Is the Solution?

Between 1998 and 2002 the U.S. experienced an unprecedented power plant construction boom that consisted mostly of gas-fired, combustion turbine – based power plants. This surge in power plant construction had several driving forces, including electric power deregulation, the emergence of non-utility power producers, a sustained period of plentiful and inexpensive natural gas, and the […]

-

Coal

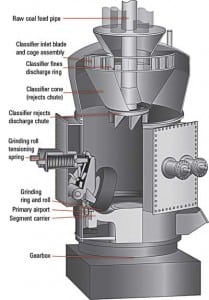

Case Histories: Pulverizer Upgrades Are Reducing Fuel Costs

St. Johns River Power Park (SJRPP) is a two-boiler, 2 x 660-MW station jointly owned by JEA (formerly Jacksonville Electric Authority) and Florida Power & Light (FPL). JEA is the plant operator. The Foster Wheeler boilers went into commercial operation in 1987 and 1988. Each boiler has seven OEM vertical spindle pulverizers (mills) and 28 […]

-

Coal

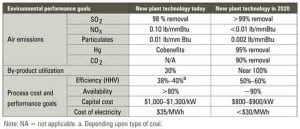

Clean Coal: Clean Coal Technology Is Not an Oxymoron

In the late 1980s, the U.S. Department of Energy (DOE), in conjunction with industry and state agencies, started the Clean Coal Technology (CCT) program. The aim of the CCT program was to develop technologies, increase efficiency, and reduce the environmental effects of burning coal in power plants. Today, pollution controls for new and existing plants […]

-

Coal

Coal Users Community: Capitalizing on Coal: The Challenges and Opportunities

Demand for energy in America continues to grow. So too does the challenge of generating it in a reliable, affordable, and an environmentally sensitive manner. Given the U.S.’s abundant coal reserves, the nation’s electric utilities are pursuing a variety of strategies to keep coal a key fuel source for generating electricity. Developing Technologies One approach […]

Search