-

Gas

Groton Generating Station, Groton, South Dakota

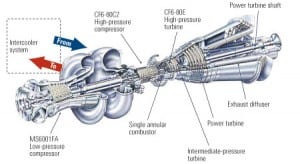

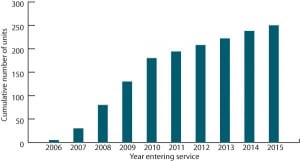

This plant’s main claim to fame: It marks the commercial debut of GE’s 100-MW LMS100 gas turbine-generator. According to Basin Electric, over the unit’s first year of service it has demonstrated top-notch operating flexibility in peaking, mid-range, and baseload service, thanks to capabilities such as 10-minute cold start-ups and minimal impact on heat rate at partial loads. In addition to hosting the first LMS100, Groton Generating Station earns recognition as one of POWER’s Top Plants for the attention its design pays to reliability and resource planning.

-

Gas

GTAA Cogeneration Complex, Mississauga, Ontario, Canada

When a blackout shuts down a factory, the impact isn’t apparent to the public. But lose power at an international airport, and thousands of angry travelers and the people waiting for them won’t be interested in excuses. The Greater Toronto Airports Authority learned that lesson in August 2003. Ten months later, it began building a 117-MW cogeneration plant that is now capable of supplying all of its energy needs—not just electricity, but space heating and chilled water as well.

-

Coal

Speaking of Coal Power: BACT to the Future

This August, Peabody Energy’s 1,600-MW Prairie State Energy Campus project in Illinois won a major federal appeals court decision, removing the last obstacle to groundbreaking. The six-year regulatory review process ended with an unsuccessful Sierra Club challenge to the $2.9 billion project’s air permit. The decision is sure to reverberate across the nation, and I […]

-

O&M

The Coal Patrol: Mine Safety Deserves More Than Lip Service

Every step forward in underground U.S. mine safety in the 20th and 21st centuries has been on the backs of mangled and dead coal miners. That grisly observation is unassailable. Following the August tragedy at the Crandall Canyon mine in Utah that killed six miners and three would-be rescuers, the federal Mine Safety and Health […]

-

Coal

PRB Tech Notes: AmerenUE Teams with Charah and Home Depot to Market Ash for Concrete Mix

Burning Powder River Basin (PRB) coal can be a curse or a blessing, depending on your attention to the details of plant design and operations. One disadvantage of PRB coal combustion is the abundance of bottom ash and flyash generated as a by-product. Handling and properly disposing of the ash can be challenging and costly. […]

-

Coal

Coal Plant O&M: How Switching to PRB Lowered O&M Costs

Lansing Board of Water & Light (LBW&L), which has generated electricity since 1892 and steam since 1919 in mid-Michigan, primarily serves the city of Lansing’s business district and all state government buildings in the downtown area. But one of the municipal utility’s plants, Moores Park, has an additional and very important steam customer: General Motors’ […]

-

Coal

Coal Plant O&M: SmartAsh Proves Its Worth

Every day, while driving to his job at PacifiCorp Energy’s Dave Johnston plant near Glenrock, Wyoming, Cole Harris used to wonder as he neared the station how opaque Unit 3’s stack emissions would look. Until a few years ago, Unit 3 (Figure 3) had trouble staying at or below opacity limits set by the state. […]

-

O&M

Plant Economics: The Impact of Shortages on FGD Prices

Since ratification of the Clean Air Act (CAA) in 1970, U.S. utilities have made steady efforts to install pollution control equipment to curb power plant stack emissions. The CAA Amendments of 1990 raised concerns at the time about the industry’s ability to install a large number of flue gas desulfurization (FGD) systems, or scrubbers, in […]

-

O&M

Mercury Control: Capturing Mercury in Wet Scrubbers: Part II

In Part I of this two-part report ( COAL POWER, July/August 2007, p. 22), we introduced the integrated R&D effort by the U.S. Department of Energy’s National Energy Technology Laboratory (DOE/NETL) to improve understanding of the mechanisms of mercury (Hg) capture and retention in flue gas desulfurization (FGD) systems and the fate of Hg in […]

-

Coal

The Coal Pile: Steam Blast Rocks Big Apple

This July, an underground steam pipe near Manhattan’s Grand Central Terminal ruptured and spewed a scalding brown geyser of steam and debris higher than the nearby 77-story Chrysler Building. The blast, which injured 30 people, created a 40-foot crater at street level that swallowed a tow truck. A similar explosion in 1989 killed three people. […]

-

O&M

Finding and fixing leakage within combined HP-IP steam turbines: Part II

By design, combined HP-IP turbines have a small amount of internal leakage from the high-pressure turbine to the intermediate-pressure turbine. As turbines age, the leakage increases considerably and becomes excessive, creating a heat rate penalty and possibly a reliability problem. Last month we explored the symptoms and causes of steam leakage within GE steam turbines and how to correct the problem. In Part II, we examine the same issues for Westinghouse and Allis-Chalmers turbines from both theoretical and practical angles.

-

Environmental

Field experience with mercury monitors

With U.S. mercury regulations pending and control technologies in the full-scale demonstration stage, accurate and reliable measurement of mercury in flue gas is becoming more important than ever. This article compares the results of field measurements of commercially available mercury monitors to approved reference methods. A key but not-so-surprising finding: Not all mercury monitors are created equal.

-

O&M

Use predictive techniques to guide your mercury compliance strategy

Several states have mandated faster and/or deeper reductions in plant mercury emissions than those called for by the Clean Air Mercury Rule. Unfortunately, differences between plants make accurate evaluation of control options difficult. In most cases, even statistically based Hg emission models don’t pass muster because they don’t account for the dynamic chemical behavior of Hg species in gas cleaning systems. This article describes one system evaluation tool that has been validated using Hg field test data from 50 full-scale flue gas cleaning systems. It is already being used by TVA and other utilities.

-

Business

Application determines DG system configuration

The intended use is the primary consideration (even fuel is secondary) when choosing an on-site energy system. Whether the need is for power alone or for heat as well, distributed generation plants have delivered lower energy costs and improved reliability to industrial and commercial customers worldwide. Following are six case studies of reciprocating engine systems that highlight their versatility.

-

O&M

Detecting and solving lube oil varnish problems

Have you bought electrostatic or agglomeration equipment to rid your turbine oil of varnish deposits, but its varnish potential rating failed to improve? Or, after an initial drop, has the varnish potential returned to its previous level? Even worse, have you had recurring valve sticking problems after making a sizeable investment to "solve" this problem? Welcome to the world of soluble varnish caused by autodegradation. Read the unvarnished truth about varnish and how to get rid of it for good.

-

Marmaduke

Marmy’s loose rivets

Steve Elonka began chronicling the exploits of Marmaduke Surfaceblow—a six-foot-four marine engineer with a steel brush mustache and a foghorn voice—in POWER in 1948, when he raised the wooden mast of the SS Asia Sun with the help of two cobras and a case of Sandpaper Gin. Marmy’s simple solutions to seemingly intractable plant problems remain timeless. This Classic Marmaduke story, originally published in 1958, illustrates that big problems often have simple, but ingenious, solutions.

-

News

Retrospective

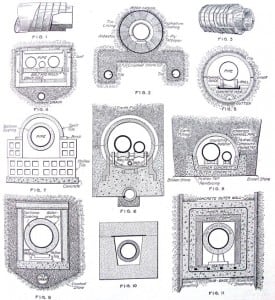

August 1886 POWER reported on one of the first twin-cylinder "Otto" natural gas–fired engines that had recently appeared in the U.S. power market. The report notes that "engines of 100 horsepower are being now economically used where gas is low in price, as in England and other European countries" (Figure 1). 1. A twin-cylinder "Otto" […]

-

Commentary

Global warming "consensus" continues to melt away

We are witnessing an international awakening of scientists who are speaking out in opposition to former Vice President Al Gore, the United Nations, and the media-driven "consensus" on man-made global warming. In May, I released a report detailing scientists who were former believers in catastrophic man-made climate change but who have recently reversed themselves and […]

-

Synfuel

Fueling around

Europeans didn’t know that corn existed before Columbus "discovered" America. It had been cultivated by indigenous North Americans for thousands of years before the Italian brought home what was to become a favorite food for many. The more adventuresome even figured out how to distill corn into something more to their liking. Fast-forward five hundred […]

-

Gas

Global Monitor (August 2007)

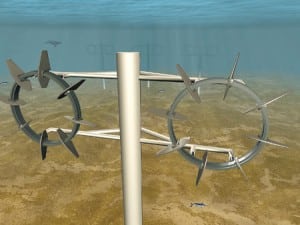

PG&E mounts tidal power project / GE F-class turbine breaks record / Iowa welcomes ethanol-fed hog / NYPA upgrades pumped-storage plant / Bush blesses Browns Ferry 1 restart / Shearon Harris looks to live on / Nevada bets on solar thermal / Climate models questioned / POWER digest

-

Readers talk back and Corrections (August 2007)

Reaction to reactor comment On page 34 of your April article on nuclear power, the author mischaracterized the maturity of one of the new reactors that have been submitted for NRC approval. The statement, "None of the advanced reactors that the NRC has certified (by reviewing engineering documents) has a performance record," is incorrect. GE’s […]

-

O&M

Focus on O&M (August 2007)

Stop valves from leaking money / Integrating plant and equipment models / Pricing priceless knowledge

-

Is ratepayer funding of utility R&D outdated?

Southern California Edison Co. (SCE) is requesting regulatory approval to recover over $50 million from ratepayers to analyze the feasibility and cost of a "commercial-scale" clean hydrogen power generation (CHPG) facility that would gasify coal to fuel a combined-cycle power plant and sequester the associated carbon emissions underground. If the study demonstrates the CHPG technology […]

-

O&M

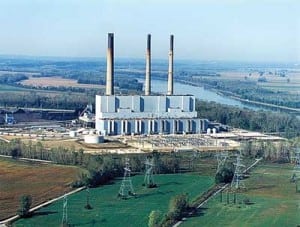

MidAmerican’s Walter Scott, Jr. Energy Center Unit 4 earns POWER’s highest honor

MidAmerican Energy Co. and its project partners are convinced that supercritical coal-firing technology’s inherently higher efficiency and lower CO2 emissions no longer come with a price: reduced reliability. Their Walter Scott, Jr. Energy Center Unit 4, the first major new supercritical plant in the U.S. in more than 15 years, is POWER’s 2007 Plant of the Year.

-

Coal

PSNH’s Northern Wood Power Project repowers coal-fired plant with new fluidized-bed combustor

The Northern Wood Power Project permanently replaced a 50-MW coal-burning boiler at Public Service of New Hampshire’s Schiller Station with a state-of-the-art fluidized-bed wood-burning boiler of the same capacity. The project, completed in December 2006, reduced emissions and expanded the local market for low-grade wood. For planning and executing the multiyear, $75 million project at no cost to its ratepayers, PSNH wins POWER’s 2007 Marmaduke Award for excellence in O&M. The award is named for Marmaduke Surfaceblow, the fictional marine engineer/plant troubleshooter par excellence.

-

Nuclear

Global Monitor (July 2007)

Pistachio plant gives new meaning to green/Slightly sun-powered grill/Will lithium revolutionize hydrogen storage?/Calpine’s major Geysers geothermal upgrade/Rhone-Alps is French PV hot spot/Fuel cell–powered ice-resurfacing machine/Westinghouse proposes revised AP100 design/Sandia perfects solar alignment/SCE wants comprehensive coal study/POWER digest

-

O&M

Focus on O&M (July 2007)

Hydro-demolition speeds reactor dome entry;

Tips for keeping your unit stable;

Air makes heavy move a breeze -

Legal & Regulatory

Cogeneration qualifying facilities warrant extended contracts

Congress’s enactment of the Public Utility Regulatory Policies Act of 1978 (PURPA) triggered a revolution in the development and construction of power plants. PURPA’s creation of an independent class of generators—qualifying facilities (QFs)—exposed a century-old economic myth that had justified restricting ownership of generating facilities to governmental and investor-owned utilities (IOUs). The success of QFs […]

-

Coal

Westar’s Lawrence Energy Center wins for not blinking on safety

It took Westar Energy eight years to upgrade the Lawrence Energy Center to burn Powder River Basin coal. Its zero lost-time accident record during the million-man-hour project is a testament to Westar’s commitment to workplace safety. Here’s your backstage pass to meet the PRB Coal Users’ Group 2006 Plant of the Year.

-

Instrumentation & Controls

Finding and fixing leakage within combined HP-IP steam turbines: Part I

By design, combined HP-IP turbines have a small amount of internal leakage from the high-pressure turbine to the intermediate-pressure turbine. When turbines are new, the amount of this leakage is close to the design heat balance. But as turbines age, the leakage increases considerably, causing a heat rate penalty and possibly a reliability problem. In Part I, we explore the symptoms and causes of excessive leakage within GE steam turbines and how to correct the problem. Part II, in next month’s issue, will examine the same issues for Westinghouse and Allis-Chalmers turbines.

Search