The POWER Interview: SMR Growth Tied to Plan for Nuclear Waste

A recent study published in the Proceedings of the National Academy of Sciences, based on research from Stanford University and the University of British Columbia, addressed the problem of nuclear waste from small modular reactors (SMRs). The study said that many designs for SMRs would increase the amount of nuclear waste in need of disposal, in contrast to what many in the industry have said about the technology—that SMRs would produce fewer radioactive byproducts than conventional large-scale reactors.

Opinions about the study’s findings may differ, but energy experts agree that solving the problem of nuclear waste will be important to the growth of SMR deployment. The issue of what to do with spent fuel has dogged the nuclear power industry for decades.

Dr. Henry Crichlow, founder and CEO of NuclearSAFE, is known for writing an engineering book that helped transform the oil and gas industry. Crichlow, a recognized expert in oil and gas, energy, and nuclear waste engineering, who has been a Distinguished Professor of Engineering and chairman of the departments of Petroleum, Natural Gas and Geological Engineering at the University of Oklahoma, helped the Kuwaiti government extinguish oil wells set on fire during the Kuwait-Iraq war, and analyzed the 2010 BP Macondo blowout in the Gulf of Mexico. Crichlow has now turned his expertise to the problem of nuclear waste. He told POWER his focus is on utilizing his “brain child,” a patented technology he developed in 1998 to utilize oil well drilling techniques as a cost-effective and scalable solution for nuclear waste disposal.

POWER: How could the issue of storage of nuclear waste slow the growth of small modular reactor technology?

Crichlow: Without a well-developed program for waste disposal in place the SMR industry is going to be slowed considerably in achieving its massive growth potential, which is needed to help mitigate climate change and also to prevent the inescapable mounting costs of onsite surface storage of their high-level waste (HLW). Today there are extremely profitable companies that specialize in surface storage of HLW in concrete casks, who are willing to store the waste for millions of dollars annually, on a cement/gravel pad behind a locked chain link fence for decades. SMRs must not be trapped into this unnecessary stop-gap, expensive dead-end operation. SMR groups should develop their own waste disposal systems to meet their needs. They should not wait for another party to lead the way.

The overriding problem is that the waste still belongs to the SMRs, and its liability and eventual disposal is just put off until the surface stored waste is eventually relocated to the final repository at an additional costs to the SMR group. SMRs have to be controllably proactive and have their final repositories ready within a matter of years of reactor implementation so that transport and sequestration of encapsulated waste can begin as soon as the waste is disposal-ready, and continue without the additional costs of intermediate surface storage.

POWER: What type of storage program should be adopted for waste from SMRs?

Crichlow: SMRs should adopt a safe, flexible, economic, scalable, and optionally retrievable, waste/disposal storage program. The SMR industry must learn from the past and not replicate the continuing mistakes of others, and solve the waste problem alongside the development and implementation of their SMRs by working cooperatively with those technology companies that can provide solutions. There are viable, economic and technical waste solutions that are available today.

Today, the nuclear energy industry is bifurcated, operating along two seemingly unconnected operational tracks. The “front end” produces electric power profitably, while the “back end” has tried unsuccessfully to find ways to dispose of the resulting spent nuclear fuel (SNF) waste. SMRs must seamlessly connect these two paths to enable the SMR industry to be successful. Historically, as the legacy power section effortlessly produced emissions-free energy for decades, the disposal end has languished unsuccessfully, spending tens of billions of dollars in a single-minded mining-near-surface approach to seek an environmental, pollution-free solution to the waste problem.

To date, waste disposal has focused on near-surface mines and tunnels, which face major insurmountable technical issues. SMRs must take an off-ramp to the mines and tunnel approach of yesteryear, and look at new solutions like the SuperLAT technology that is underpinned by hundreds of thousands examples of successfully drilled horizontal wellbore developments worldwide. Unless the SMR industry wants to be like the rest of the world, where billions have been spent with no viable solution yet achieved, it must prepare its waste disposal solution from the start, from day one and move in a different direction.

SMR advocates must have a flexible developed waste program, which starts with technical analyses similar to what is routinely done in oil and gas exploration to find the optimal very deep geological zones for waste disposal. The selection of these zones should be complementary to the location of the SMRs if possible, for economic and safety reasons. The SuperLAT repository may be co-located within the compound where the SMR is built, if possible.

This SuperLAT patented technology is robust, well developed, and available today. It costs millions, not billions, and a SMR repository can be implemented in less than six months once the disposal site is selected.

Current plans for near-surface mines or tunnel disposal systems would take two to three decades and would need additional billions of short-term fixes that many never work as a long-term solution.

More importantly, the existence of well-developed oil and gas operations infrastructure throughout the world eases the implementation of the SuperLAT disposal system since the manpower, equipment, goods, and command-and-control services are already positioned strategically worldwide.

POWER: Countries such as Finland and Sweden have made good progress with waste storage, particularly with deep geological storage. Is this the best method of storage, and if so, why?

Crichlow: As a scientist, researcher and practicing professional engineer with 50 years of experience in areas related directly and indirectly to high-level waste disposal, the quick answer is a resounding “No!” This attempt to store the HLW in near-surface zones, such as near-surface mines and tunnel repositories (NSMTR) that are in, or close to, the existing subsurface water table, and then try to protect the stored waste with “backfill material,” copper canisters, titanium “umbrella” shields, is not a realistically viable 10,000-year solution for such toxic materials.

Today, and for prior decades, the high-level nuclear waste industry has focused single-mindedly, following each other, almost blindly, on a near-surface “mine or tunnel” approach for the long-term disposal of HLW. In the U.S., Yucca Mountain, in Canada, the DGR, in Europe. Finland and Sweden have moved ahead of the rest of the world.

This approach is simply not a viable solution today. Some experts believe that a successful NSMTR for HLW disposal may never be implemented, anywhere on Earth, regardless of the billions of dollars and decades of time expended in the fruitless effort. Better solutions are available.

This negative opinion is based on several published discussions on the obstacles to the proposed NSMTR solution. One major obstacle to successful NSMTR implementation is the Chlorine-36 problem that exists with respect to the NSMTR approach. Chlorine-36 is the “smoking gun.”

Without going too deeply into the weeds, technically, Chlorine-36 is a naturally occurring chlorine radioisotope and typically has been present in rainwater at a certain stable and predictable concentrations. It is a marker which can “fingerprint” the water with respect to age. Chlorine-36 by its existence in the water in these NSMTR systems, indicates insurmountable and unimpeachable evidence or obstacle to the NSMTR approach to HLW disposal. The current (2020) elevated ratios of Chlorine-36 found in what is nominally called “modern water” has only been caused by the detonations associated with nuclear bomb testing in the atmosphere in the 1950s. Those high ratios did not exist pre-1950s. This “modern water” has percolated downward into those zones that are being considered for waste disposal today.

Applying an exhaustive analysis of Chlorine-36 in the interstitial waters surrounding and permeating the near-surface NSMTR layers of the earth, it is shown conclusively and scientifically that surface (and near surface) waters have migrated and shall continue to migrate downward and eventually reach any NSMTR-stored HLW material there below, in as short a period as 50 years. This is much too brief, since HLW materials require at least 10,000 years or so of environmental isolation for safe disposal. The inevitable chemical, physical, and electrolytic degradation of HLW materials stored in an NSMTR system shall occur, regardless of any subsequent artificial protective systems later implemented, like titanium umbrella sheets, added retroactively, as recommended by some scientists to protect the HLW containers after initial HLW disposal. There are also other technical reasons.

Additional reasons why this massive operation method is not the best, nor even appropriate: Operationally today, there is no need for “a town on the surface and a village underground” to safely dispose of HLW, as all these NSMTR systems are advocating, with hundreds of workers on the surface and underground in working facilities with built-in safety, ventilation, transport, and escape systems. These massive, fully staffed, “mining” type operations are expensive, dangerous, inefficient, long-term operations and prone to catastrophic human error that can shut down a multi-billion dollar, multi-year project in its tracks. A recent “incident” in a near-surface disposal operation occurred at the Dept. of Energy’s WIPP in New Mexico, where a simple air-shaft malfunction and radioactive leak problem shut down operations for years with a billion-dollar price tag to fix it.

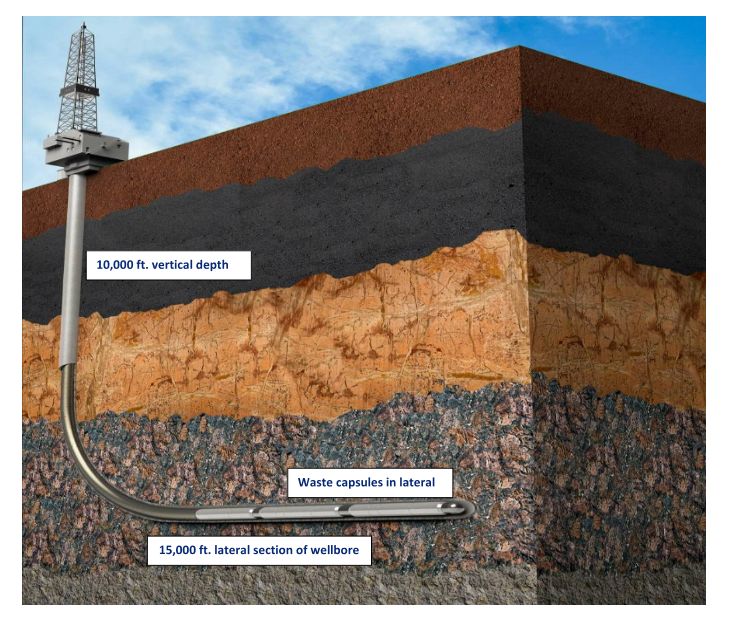

There is a better way. One of these new solutions has come along. It is the “brainchild” of oilfield operations, the SuperLAT technology (proposed, developed, and patented by Crichlow in 1997), as a safe, economic, readily deployable means of resolving this intractable waste problem. The SuperLAT system sequesters the encapsulated waste in deep, long horizontal wellbores strategically drilled well below 10,000 feet in impermeable rock zones. This can be done within a period of months. These geological disposal zones have been shown by radioisotope dating to have been hydraulically closed for at least 10 million years. The deep impermeable formation is considered the ultimate protection for the waste. The capsules are simply short-term (10,000 years) devices to transport and sequester the waste in the deep repository formation rapidly and safely.

This SuperLAT technology today allows the disposal of thousands of metric tons of high-level waste capsules in a single deep horizontal wellbore. It forms a safe deep repository for waste in impermeable rock formations by drilling more than 10,000 feet below the surface, and then extending up to an additional 15,000 feet laterally. Waste in cylindrical capsular form can be quickly and easily placed in these deep repositories. These systems can be drilled in mere months, and ready for the safe disposal of all the waste produced by SMRs as soon as the waste sufficiently cools at the SMR cooling ponds.

This novel patented technology is robust, well developed, and available today. It costs millions, not billions, and a repository can be implemented in less than six months. A typical SuperLAT operation can involve less than 30 workers on the surface to drill, load, and dispose of more than 1 million pounds of encapsulated waste at a cost of less than $25 million to $50 million.

POWER: Many energy analysts see nuclear power as critical in the fight against climate change, as it at present would be the largest source of zero-emission, baseload power. What needs to happen to support more widespread adoption of nuclear?

Crichlow: There is only one prerequisite that when fulfilled can increase the public support for and adoption of nuclear waste. This simple prerequisite is the safe disposal of the HLW in a system that is far removed, physically, metaphorically, and visibly distant from any human contact, interference, or intervention. The nuclear waste should literally be in a repository, or in a zone that humans instinctively consider forever buried. This approach means an extremely deep, miles below the surface, miles below the water table, and greater than 10,000 feet to 15,000 feet below ground in a horizontal repository that is demonstrably forever closed. By demonstrating this type of deep, horizontal high-capacity burial, in well-engineered waste capsules, the SMR industry would show to the world that it is serious about HLW safety, rather than hiding the waste in plain sight, in surface concrete casks sitting in a grid pattern on a concrete pad with each of hundreds of casks being a possible point of environmental failure. It is even contemplated that many years into the future these deeply buried cylindrical capsules may be retrieved from the sealed horizontal wellbore for beneficial use in some new yet undiscovered, advanced nuclear technology.

POWER: Are there lessons the nuclear power industry could learn from other industries, such as oil and gas exploration, that could solve some of the challenges around nuclear power?

Crichlow: As a scientist/researcher/engineer, and based on my expertise in the oil and gas industry and scientific research academically and industrially, I believe that the SMR industry can learn a lot from the oil/gas industry.

For example:

- Adopt independent/competitive/intelligent thinking that can drive technology changes in waste disposal. SMR developers should not follow the lead of others and more importantly, SMR should develop an independent investigative attitude that has been shown to be historically innovative drivers in the oil and gas industry for decades. Most current repository development across the globe has been spawned by the ill-fated and massively expensive, to the tune of $20 billion in the U.S., Yucca Mountain effort which is now dead in the water. This has only occurred because all major waste disposal publications were produced by experts or authors wearing “blinders,” who considered the Yucca Mountain effort or its derivatives as the “gold standard.” They did not look at all the technology that was available in patents, oil, and gas journals or in field operations of horizontal wellbores since the 1980s..

- Select multiple sites for potential deep repository development, and focusing on a best/optimal site ranking now, in some cases the deep repository may be beneficially co-located within the power plant compound itself. If one site is subsequently shown to be questionable there is a list of available sites “waiting in the wings.”

- Pattern development of repository sites in which SuperLAT repository wellbore systems are developed on an areal grid pattern as done in major oil field development. This well-documented approach shall maximize disposal capacity and lower SMR operating costs considerably.

- Parallel planning-ahead and implementation, to have a SuperLAT deep horizontal wellbore repository ready in place and functioning in parallel with the SMR development. In the oil and gas industry we build a pipeline or a production platform to pipe the oil/gas to its final location even while the first exploratory well is being drilled. Just in time (JIT) technology should be the norm or the basis of SMR development.

- Developing a lean, streamlined and the minimal footprint and logistic infrastructure for waste disposal. As indicated herein earlier, we do not need, “a town on the surface and a village underground” to fulfill the needs of effective and efficient HLW disposal; that approach may provide low-level jobs but does not add to the solution of the waste disposal problem. Furthermore, it is dangerous and an unproductive use of a country’s or a company’s funds.

—Darrell Proctor is a senior associate editor for POWER (@POWERmagazine).