Slide Show Supplement to Mátra Power Plant, Visonta, Hungary

The Mátra Power Plant in Visonta, Hungary, uses a dense slurry system for handling fly ash and other coal combustion residuals. The DSS combines ash and water in a 1:1 ratio, creating a cement-like slurry.

<

►

>

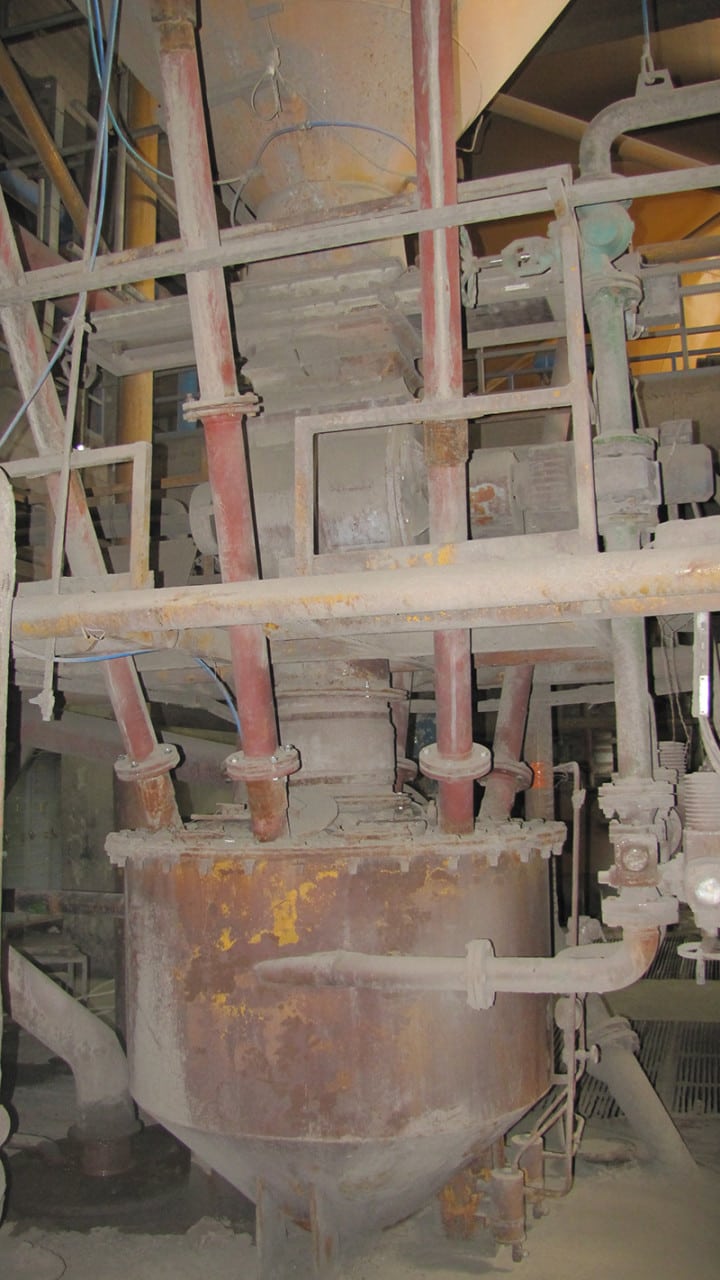

The Mátra Power Plant in Visonta, Hungary, uses a dense slurry system (DSS) for handling fly ash and other coal combustion residuals. The DSS combines ash and water in a 1:1 ratio, creating a cement-like slurry. Ash enters the top of the system through the ash feeder (top). Courtesy: Enexio