POWER

-

Balancing risks and rewards

More top utilities are making plans to add one or more integrated gasification combined-cycle (IGCC) plants to their generation portfolios over the next decade. Some 25 separate projects are on the drawing board, virtually all planning to use Eastern coal. Western coals pose tougher challenges for gasifiers, and their lower heat content disadvantages project economics. […]

-

Coal

Global Monitor (October 2006)

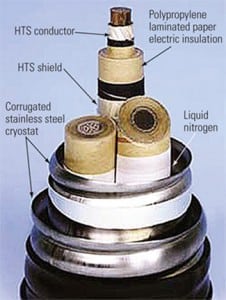

First live superconducting cable / Biggest CO2 storage project / Largest hydrogen-fueled plants / Record run for fuel cell cogen system / Largest PV plant still in Bavaria / Luz returns to U.S. / POWER digest

-

O&M

Focus on O&M (October 2006)

Upgrading to digital–twice / Lower-cost turbine monitoring / Pros and cons of remote process control / Nuts about Superbolt

-

Legal & Regulatory

Restricting bids for new capacity raises costs, lowers reliability

Most sponsors of bid solicitations seek to attract the maximum number of high-quality bids. Basic economic principles tell us that the greater the number of respondents to a solicitation, the greater the competition and the greater the benefits to the solicitor. Somewhat counterintuitively, and notwithstanding California’s need for more electricity supply, the state’s utilities are […]

-

O&M

Apply the fundamentals to improve emissions performance

The O&M staff of AES Westover Station wisely took a holistic approach to optimizing combustion within Unit 8’s boiler in order to reduce its NOx emissions while maintaining acceptable levels of carbon-in-ash content. The results of major modifications—centered on the addition of a fan-boosted overfire air system—were a 60% reduction in NOx levels, improved unit reliability, and a project payback period measured in months rather than years. As this project proved, the whole is more than the sum of its parts.

-

Coal

Designing and upgrading plants to blend coal

Fuel flexibility isn’t free. Whether you’re equipping a new power plant to burn more than one type of coal or retrofitting an existing plant to handle coal blends, you’ll have to spend time and money to ensure that all three functions performed by its coal-handling system—unloading, stockout, and reclaim—are up to the task. The first half of this article lays out the available options for configuring each subsystem to support blending. The second half describes, in words and pictures, how 12 power plants—both new and old—address the issue.

-

Coal

Expert systems optimize boiler performance, extend plant life

Slagging and fouling of furnaces and boilers’ convective pass top the list of costly coal plant O&M problems. Although sootblowing is a tried and true solution, running sootblowers too often can erode boiler tubes. Lehigh University’s Energy Research Center has developed an "expert" sootblowing system that has outperformed experienced operators’ "seat of their pants" sootblowing procedures on two head-to-head field tests.

-

Coal

Utilities split on readiness of IGCC

For some gencos, the dearth of operating experience for integrated gasification combined-cycle plants adds too much uncertainty to the risk/reward equation for new-capacity technology options. For others, the possibility of being able to comply with air pollution limits as far out as 2018, as well as to meet all-but-certain CO2 caps, makes IGCC well worth investing in—now.

-

Coal

Technology options for capturing CO2

Concerns about global climate change have prompted interest in reducing or eliminating the carbon dioxide (CO2) emissions of fossil fuel-fired power plants. Here’s a guide to the technology and economics of three CO2 capture methods: postcombustion separation of CO2 from flue gas (applicable to existing plants), and oxygen-fired combustion and precombustion capture (suitable for new coal-fired capacity, including IGCC plants).

-

O&M

Meeting utility industry challenges through innovation

In 2005, Xcel Energy fully implemented its unique Utility Innovations initiative to encourage its IT vendors to work together. One pilot project completed under the UI umbrella confirmed that tighter integration of predictive and analytical systems and data can optimize preventive maintenance intervals, reducing costs and downtime while increasing profits and productivity.

-

O&M

Monitoring key gases in insulating oil keeps transformers healthy

Large T&D-sized transformers age as quickly as generating assets do. But preventing transformers from failing is difficult because they have no moving parts and are sealed up. Tracking the concentrations of certain gases—the more, the better—that are dissolved in a unit’s insulating oil is a proven way of detecting damage before it causes a costly problem.

-

Business

Shaving load peaks from the substation

The first megawatt-class sodium sulfur (NaS) battery placed in service in North America was installed this June in Charleston, W.Va. The 1.2-MW system—comprising the battery and a bidirectional inverter—can be discharged during the day to provide 7.2 MWh of on-demand power for shaving peak loads and be recharged at night. It’s no longer true that electricity can’t be stored, except in small quantities.

-

Commentary

Turning the corner on global warming

In his keynote speech this May to the Global Roundtable on Climate Change, held in Iceland and hosted by the Earth Institute of Columbia University, Ólafur Ragnar Grimsson—the president of Iceland—challenged government and business leaders to take measurable steps now to build a prosperous and sustainable future through smart science and public policy. Grimsson’s call […]

-

O&M

SO3’s impacts on plant O&M: Part I

The visible consequences of sulfuric acid aerosol emissions—opaque stack emissions called “blue plumes”—are merely the tip of an iceberg. In sufficient concentration, SO3 also can increase corrosion and fouling of equipment and components downstream of the furnace while decreasing their efficiency and penalizing overall plant heat rate.

-

Legal & Regulatory

Renewable contracts merit longer terms

The length of term allowed for power sales contracts is a critical determinant of the ability of states to meet their increasingly ambitious renewable power targets. Many utilities advocate limiting terms to 10 or perhaps 15 years for renewable energy contracts, emphasizing the "flexibility" that shorter terms offer. In contrast, contract terms of 20 or […]

-

Coal

Tri-State Generation and Transmission Association’s Springerville Unit 3 earns POWER’s highest honor

It’s said that pioneers take the arrows. In the case of Springerville Unit 3—a 418-MW (net) expansion of a Tucson Electric Power facility in Arizona and the first pulverized coal–fired unit built in the U.S. in more than a decade—the arrows were many. Although Tri-State (the developer), Tucson Electric (the host), and Bechtel Power (the EPC contractor) were wounded by delayed deliveries of major equipment, bankruptcy of a major supplier, and a labor shortage, the companies showed their pioneering spirit and completed the project ahead of schedule. For ushering in a new generation of clean and desperately needed baseload capacity, Springerville Unit 3 is POWER magazine’s 2006 Plant of the Year.

-

Coal

Nova Scotia Power’s Point Aconi plant overcomes CFB design problems to become rock of reliability

Point Aconi’s circulating fluidized-bed boiler experienced erosion, corrosion, and fouling problems from the day it went on-line in 1993. After several frustrating years of unreliable operation, in late 1999, Nova Scotia Power discovered the right combination of engineering and fuel modifications. Today, after a switch to 80% petroleum coke and major boiler modifications, Point Aconi’s output exceeds its original nameplate rating. For having the vision and fortitude to plan and execute a multiyear, $20 million project to revitalize North America’s first in-service utility CFB boiler, Nova Scotia Power’s Point Aconi plant is the well-deserved winner of POWER magazine’s 2006 Marmaduke Award for excellence in O&M.

-

Water

Organics in the boiler and steam: Good or bad?

Among utility chemists, opinions differ on the effect that organic compounds—both naturally occurring types and those added as treatment chemicals—have on the steam cycle. Some chemists raise the specter of corrosion of low-pressure turbines caused by organic acids created as the compounds degrade. Others defend and encourage the use of organic treatment chemicals, particularly neutralizing amines, by pointing to a long and positive history of their use in boiler and feedwater systems.

-

O&M

How to conduct a plant performance test

Performance testing after initial start-up has value well beyond the short-term goal of validating equipment guarantees—it’s your only opportunity to establish the baseline performance of the overall plant and many of its major systems. Corporate bean counters may be interested in short-term results, but a good plant engineer understands that a thorough performance test will be useful for many years. Here’s your guide to each facet of a performance test—plus pitfalls to avoid.

-

Coal

How accurate are your reported emissions measurements?

Complying with permitted emissions limits may be the most significant operations risk for a power plant. As limits are slowly ratcheted downward, understanding the accuracy and variation of measured pollutant levels becomes even more important. To avoid misunderstandings, regulators and plant owners should factor measurement uncertainty into air quality permit numbers both as the permit is formulated and preceding any subsequent modifications.

-

Business

Mandatory reliability rules are coming. Are you ready to comply?

An extremely reliable North American bulk power system—one that consistently delivers uninterrupted power to every user—is not a dream that must be made reality. To a large extent, that is what we have today. With the exception of infrequent (and therefore, newsworthy) outages, the system has never been more dependable. Nevertheless, with the great northeast blackout of August 14, 2003, still fresh in memory, Congress saw fit to include electric reliability measures in the Energy Policy Act of 2005.

-

Instrumentation & Controls

Cleaning and inspection of stainless steels and nickel alloys for FGD service

Stainless steels and nickel alloys of the C-family are major materials of construction for flue gas desulfurization systems. Both types of materials depend upon the presence of thin, passive, chromium-rich, surface-oxide films to provide the desired corrosion resistance. Corrosion resistance is optimized by proper cleaning before and after fabrication. Here are some guidelines for keeping those materials clean.

-

Marmaduke

Marmy’s medicine show

Steve Elonka began chronicling the exploits of Marmaduke Surfaceblow—a six-foot-four marine engineer with a steel brush mustache and a foghorn voice—in POWER in 1948, when Marmy raised the wooden mast of the SS Asia Sun with the help of two cobras and a case of Sandpaper Gin. Marmy’s simple solutions to seemingly intractable plant problems remain timeless.

-

Commentary

Combating climate change

The overriding environmental challenge of our time is climate change. The problem originates from the emission of greenhouse gases, primarily carbon dioxide, mainly from the transport and energy sectors. If humanity fails to come to terms with this problem, we will be forced to make dramatic changes in the way we live our lives, but […]

-

News

National pastime

—Dr. Robert Peltier, PE Editor-in-Chief During every summer hot enough to break peak demand records, the rhetoric heats up as well, with calls to rid the U.S. bulk-power system of bottlenecks. As the eternal optimist, I see large transmission projects showing signs of life and grid reliability improving. But not everyone is happy about that. […]

-

Coal

Global Monitor (September 2006)

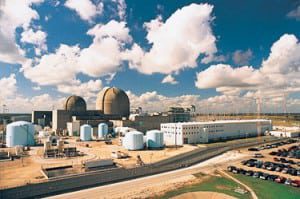

Demand records fall nationwide;

GE’s ABWR to be STP’s edge; Entergy buys Palisades plant; Dithering over desert disposal; Tourist trash-to-energy plant;

Brooklyn says "Yo!" to microturbines; POWER digest -

O&M

Focus on O&M (September 2006)

Level measurement in harsh environment;

Designing insulation for structures;

Shockingly clean boiler

-

Coal

Bethlehem Energy Center, Glenmont, New York

A great location, a fish-friendly cooling system, and the extent of environmental remediation needed to permit it distinguish this repowering project on the Hudson River just south of the New York State capital.

-

Gas

Brooklyn Navy Yard Cogeneration Facility, Brooklyn, New York

The Brooklyn Navy Yard Cogeneration facility supplies critical electricity and steam to New York City. Situated on an historic site, the plant has earned a series of awards and was the first cogeneration plant to be accepted into both the U.S. EPA National Environmental Performance Track and OSHA’s Voluntary Protection Program in 2005. Through Delta Power’s unique asset management approach that brings added value to projects, BNYC has reinvented itself from a struggling, prematurely aging facility into one of the nation’s leading plants.

-

Coal

Currant Creek Power Plant, Mona, Utah

Commercial operation of PacifiCorp’s first new power plant in more than 20 years coincided with the company’s acquisition by MidAmerican Energy Holdings Company this past March. Currant Creek treads lightly on the environment, provides needed power to PacifiCorp’s eastern control area, and has demonstrated its commitment to be a good corporate citizen of the local community. By any account, Currant Creek is a model for how to develop a power project.