OPG Becomes First Utility to Snag Ownership Stake in Nuclear Microreactor Project

Marking the first time a utility has taken an ownership stake in a small modular reactor (SMR) project, Ontario Power Generation (OPG) formed a joint venture with Seattle-based Ultra Safe Nuclear Corp. (USNC) to build, own, and operate a proposed Micro Modular Reactor (MMR) demonstration at the Chalk River Laboratories (CRL) site in Ontario, Canada.

If built, the project could be Canada’s first commercial deployment of a private sector–funded SMR. The move announced on June 9 is also a notable, definitive signal that the power sector is willing to invest in a burgeoning movement to commercialize advanced nuclear reactors. It comes on the heels of progress made by several SMR and microreactor vendors relating to advanced nuclear reactor demonstrations, licensing, and advanced nuclear fuel development.

The joint venture, which will be called, “Global First Power Limited Partnership,” stems from a long-standing partnership comprising OPG, Ontario’s largest generator; USNC, a company that is developing the 5-MWe (15-MWth) MMR technology as well as proprietary advanced nuclear fuel technology; and Global First Power (GFP), which is an Ottawa-headquartered firm that specializes in SMR project development and project financing.

OPG and USNC subsidiary USNC-Power will hold equal stakes in the joint venture to build and operate the proposed MMR project, while GFP will act on behalf of the partnership to oversee the project, and provide project development, licensing, construction, and operation of the commercial demonstration reactor at the Chalk River site.

Securing a Site

For now, however, the project developers have yet to secure the demonstration site. Chalk River Laboratories is owned by Atomic Energy of Canada Limited (AECL) and operated by the Canadian Nuclear Laboratories (CNL), Canada’s nuclear science and technology agency. In 2017, as part of a long-term strategy, CNL set a goal to site an SMR at the sprawling 10,000-acre Chalk River site by 2026.

Several SMR developers have applied for the opportunity in response to a public invitation, including Terrestrial Energy and Starcore Nuclear, which have so far completed the pre-qualification stage. The MMR project, notably, leads that contest and is now in the third stage of the CNL’s four-stage process. The third stage essentially involves discussions about land arrangements, project risk management, and contractual terms—and it would culminate in the signing of an agreement with AECL. In the fourth and final stage, the developers would enter project execution—and that would entail licensing and construction, testing, commissioning, operation, and eventual decommissioning of the SMR unit.

CNL wants to begin operating an SMR by 2026, but is still unclear if and when the fourth stage for the MMR would begin. As Mark Mitchell, USNC-Power told POWER on June 12, that would depend on completion of the environmental assessment (EA) and licensing activities, as well as obtaining a License to Construct. Those are “processes we do not control,” he said.

Progress is continuing on the July 2019–initiated EA for the proposed MMR project, which, notably, was the first for an SMR in Canada for the Canadian Nuclear Safety Commission (CNSC). The MMR has also so far cleared the first phase of the CNSC’s Vendor Design Review is now awaiting Phase 2 review. These milestones are “still very early in the process,” noted GFP. After successful completion of the EA, the company will still need to clear a series of CNSC regulatory licenses, “each of which will include the opportunity for Indigenous community, public and stakeholder input.”

Simplicity Is a Virtue

Still, these are major first steps for USNC, a company founded only in 2011 as a spinoff from the U.S. Department of Energy (DOE) laboratories. “While there are many small reactor companies boasting about the progress they’re making, no other organization is closer to constructing a microreactor in Canada than we are,” Francesco Venneri, USNC CEO noted on June 9.

Among advanced nuclear reactor developers making similar headway is NuScale, which is thought to largely lead the race to commercialize the first SMR technology in North America because it plans to put the first of 12 60-MW modules online online at the Idaho National Laboratory (INL) by 2026. NuScale is also expected to complete all phases of the U.S. Nuclear Regulatory Commission (NRC’s) design review by September 2020 (it is unclear if COVID-19 has altered those timeframes). While NuScale has a number of projects under development worldwide with a number of backers, including UAMPS, an energy services interlocal agency of the State of Utah, it has no formal utility project stakeholders. While UAMPS has garnered substantial interest from 34 members, a final vote to proceed to construction on the NuScale 12-module plant at INL is expected in 2023.

One reason for USNC’s success, as Mitchell explained to POWER last year, is that the small technology firm has vertically integrated “all stages of the fourth-generation nuclear power production.” The company’s 5-MWe (15-MWth) MMR microreactor—a high-temperature gas-cooled reactor (HTGR)—is based on USNC’s proprietary Fully Ceramic Micro-encapsulated (FCM) fuel technology. It uses tristructural-isotropic (TRISO) fuel, which is a “new approach to inherent reactor safety by providing an ultimately safe fuel,” Mitchell said.

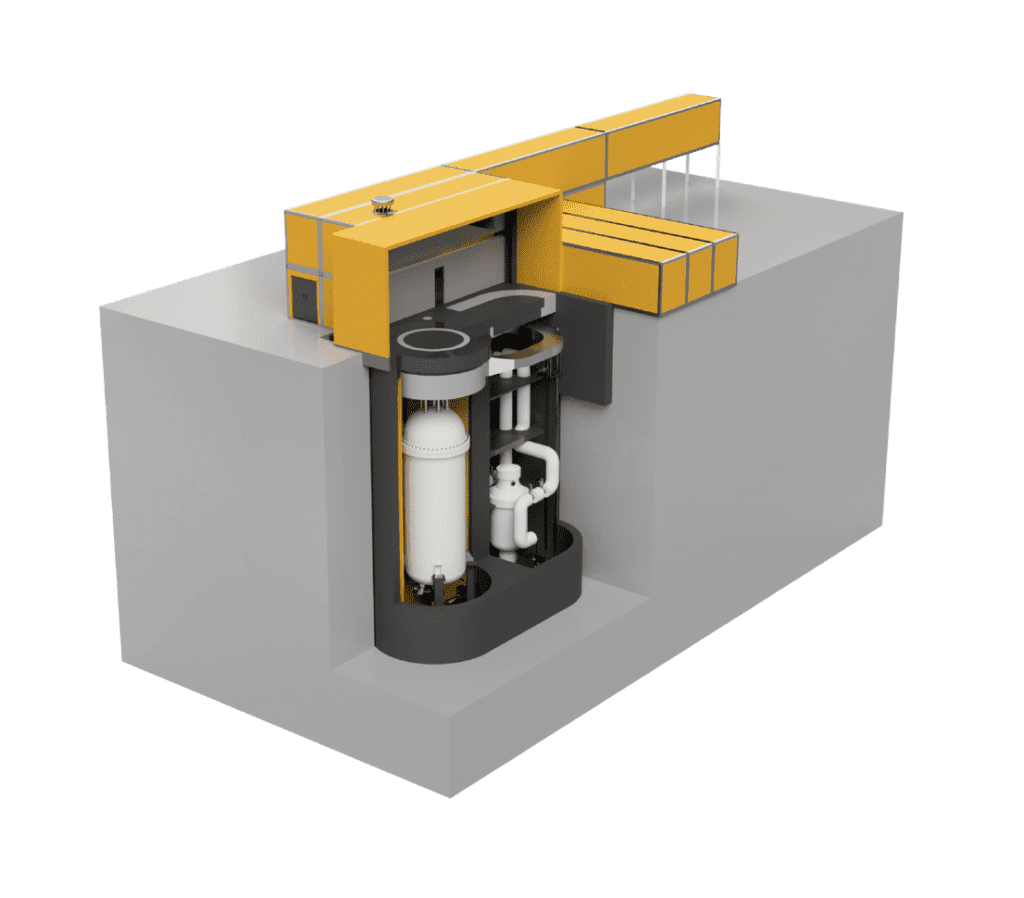

As significantly, the MMR’s design is based on “simplicity,” he noted. An MMR reactor consists of two plants—the nuclear plant, which generates heat, and an adjacent power plant that uses a steam turbine to convert heat into electricity or provides process heat for industrial applications. The helium-cooled reactor core consists of hexagonal graphite blocks containing stacks of FCM fuel pellets, which enable a low power density (of about 1.24 watts per cubic centimeters) and a high heat capacity (with an estimated outlet temperature of 630C), resulting in “a very slow and predictable temperature changes.” Also notably, the reactor is fueled once for its 20-year lifetime. “The plant has no need for active systems to remove heat. Additionally, the plant does not need any outside services, including electrical power, to operate safely,” Mitchell noted.

Meanwhile, because it’s so small—it stands at 12 meters tall and three meters in diameter—it offers construction flexibility using standardized modules, which will be pre-assembled, commissioned, and tested. Modules are sized for standard International Standards Organization shipping containers—which means they can be transported by ship, rail, or road. Once on site, construction of a plant will be “quick, simple, and scalable.” MMRs can be linked together to provide as much as 50 MWe and 150 MWth, or a combination, or as customized to site needs, Mitchell said.

And because FCM fuel cannot be reprocessed, and the core is sealed, there are no risks of spills; it needs no external water or power because the “heat generated by the core is removed passively through the natural convection of the the helium,” the MMR plant is highly suitable for standalone remote applications. That opens up new markets and possibilities for nuclear, he said, such as for microgrids, or power-hungry regions that lack infrastructure, such as in Africa.

A Business Interest for OPG

OPG’s interest in the project stems, meanwhile, from long-term plans to expand its business. At the end of 2019, OPG had a 17-GW generation fleet, most of which was hydropower, but it also owns two nuclear generating stations, the four-unit, 3.5-GW Darlington Nuclear Station and the six-unit 3.1-GW Pickering Nuclear Station, which provide nearly half of Ontario’s electricity.

Because nuclear power is “consistent with its business imperatives,” along with goals to mitigate climate change, OPG in 2016 embarked on a renewal plan for its nuclear plants, and despite the pandemic, on June 4, it marked the first major milestone of the refurbishment project to reconnect Darlington 2 ahead of schedule, and extend its operational life by 30 years. And while work will begin to refurbish Darlington 3 later this year (and on Unit 1 in 2022, and Unit 4 in 2023), OPG is also eyeing new nuclear reactors at the Darlington site. It says that while no decision on technology has been made, it plans to submit a license renewal application in mid-2020.

The active partnership with GFP and USNC on the MMR project also caters to efforts in Canada to accelerate SMR deployment. In December 2019, the provinces of Ontario, Saskatchewan, and New Brunswick entered into a memorandum of understanding to develop a business case and strategic plan for the deployment of SMRs, including market opportunities across Canada and across the world. “We are excited about the advancement of low-carbon small modular reactors in Canada and see them as an innovative growth opportunity for our company, one that fits well with our existing clean energy portfolio,” noted Ken Hartwick, OPG president and CEO, last week.

The Proposed Chalk River Demonstration

If built, the MMR project could generate about 15 MWth of process heat for power or heat to Chalk River Laboratories for CNL as the potential end-user (no offtake agreement has yet been executed). But for GFP, which is tasked with building and operating the plant, the commercial demonstration will also crucially “serve as a model for potential future GFP projects across Canada, to provide safe and sustainable low-carbon power and heat to industries, such as mining, and remote communities.”

During a May 20 community telephone “town hall,” GFP Communications Director Eric McGoey explained that the proposed MMR demonstration was less about showing the technology will work, and more an “attempt to prove that our technology is [an] economically competitive alternative to diesel power.” It isn’t “a science experiment, it really is a business experiment,” because the “technology that we’re using is well understood, it’s been tested in labs in a number of settings and we’re quite confident that it’s safe and it’s going to work,” he added .

While overall project costs will still be determined by the EA process, and detailed project design, “it’s fair to say we expect this project will cost probably at least C$100 million, and we hope at the high end, it wouldn’t cost more than C$200 million.” Those figures are highly dependent on the use case, McGoey suggested. CNL may choose to feed the power to the grid under a power purchase agreement, but if it finds the heat more valuable, for example, for hydrogen production or for process heat, “then we might not actually have to build those turbines to convert it to electricity at all,” he said.

The dual capacity is a lucrative attribute that could allow it to be competitive. GFP, for example, was under “no illusion” that the MMR would face competition from renewables, McGoey said. “I don’t expect Quebec or Manitoba or British Columbia, or Newfoundland and Labrador to get excited about modular reactors. Simply because they are blessed with hydroelectric resources that are so tremendous that they can likely supply all of their energy needs for the foreseeable future, and so what this is really about is those jurisdictions that don’t have those hydro assets. What can they do to move off fossil fuels?” he asked.

SMRs may provide good decentralized alternatives, with the benefit that they are baseload and carbon-free sources of power. Beyond that, the MMR, specifically, may be also able to offer load following. “It would probably take approximately six hours to start up the plant and achieve full power. The plant itself can load follow at approximately 10% per minute relatively easily, and we’ve also gotten [an] intermediate molten salt loop, which is something that we’ve taken from the concentrated solar–type plants, operating in a manner in which we can store thermal energy, and therefore it’s also very ideal for providing peak power during certain periods,” explained GFP Technical Director Neil Kemp.

“We have looked at the possibility of combining these reactors with wind and solar, and in certain areas that would be very beneficial—for large portions of, let’s say, in the Arctic, in Canada, [which is not] ideally suited for solar specifically, and even wind is problematic in a lot of areas. But where it is potentially possible, we would combine it in order to basically provide the most cost optimal solution for the power generation side,” said Kemp.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).

Correction (June 16): A previous version of this article stated that that the Darlington and Pickering generating stations are leased on a long-term basis to Bruce Power. OPG owns and operates the two plants in Clarington and Pickering, Ontario. OPG also owns two nuclear generating stations in Ontario, the Bruce A GS and the Bruce B GS (together, the Bruce nuclear generating stations), which are leased on a long-term basis to Bruce Power.