Hydropower: Meeting Growing Needs with Improved Reliability and Efficiency

Hydropower delivers a range of benefits to society and the environment. However, there are two major challenges that face hydroelectric power plant operators—efficient use of water and high availability. To meet these requirements there is a transformation taking place within hydroelectric plant operations enabling them to become safer, smarter, and more sustainable, supporting their important and growing position as an uninterrupted renewable energy source.

Hydroelectric power is a vital resource that is driving greater decarbonization throughout the energy sector. Its contribution to overall power supply is readily apparent; you only have to look at figures from the International Hydropower Association that show that electricity generation from hydropower reached an estimated 4,200 TWh in 2018, setting the highest ever contribution from a renewable energy source. An estimated 21.8 GW of hydroelectric power capacity was put into operation, including nearly 2 GW of pumped storage, bringing the world’s total installed capacity to 1,292 GW.

Hydropower delivers a range of benefits to society and the environment. Power-related benefits include clean and flexible generation and storage, as well as reduced dependence on fossil fuels and avoidance of pollutants. But beyond that, it has an important role to play in mitigating the intermittency of other renewable resources. Wind power relies on the wind blowing, solar power relies on the sun, but hydropower uses water, whose use can be controlled and power dispatched when it is required. However, the water available for hydroelectric plants is finite.

This explains the two major challenges that face hydroelectric power plant operators—efficient use of water and high availability of the facilities to ensure that electricity can be dispatched on demand. To meet these requirements, there is a transformation taking place within hydroelectric plant operations, enabling them to become safer, smarter, and more sustainable, supporting their important and growing position as an uninterrupted renewable energy source.

Increasing Availability with Predictive Maintenance

With many hydro plants aging, and very few greenfield plants added, there is a rapidly growing need for management to get the best out of their assets, as well as to optimize process and performance by making the most out of the information the digital era can offer them. At the core of ensuring availability of hydroelectric power plants is a rigorous maintenance regime.

Strategic approaches to maintenance and asset management have evolved over the years, thanks to the convergence of sensors, improved high-speed communications, and enhanced computing, including cloud, edge, and machine learning. Operators are increasingly evaluating their maintenance maturity and looking for new approaches to optimize assets, increase efficiency and reliability, and plan more wisely. A good example of this is offered in Italy, where ABB is working with Enel Green Power on predictive maintenance solutions that will lower maintenance costs and improve the performance, reliability, and energy efficiency of a fleet of 33 hydroelectric power plants.

Delivering more than 65% of Italy’s hydropower, Enel is aware that predictive maintenance and asset performance management must become a key component of its strategy to optimize maintenance operations, minimize risk, improve resilience, and reduce costs. The 100 units at these plants will move from hours-based maintenance to predictive and condition-based maintenance by utilizing the ABB Ability Asset Performance Management solution.

The two companies have been working closely for two years, and have developed and tested predictive maintenance and advanced solutions through a pilot project at five Enel plants in Italy and Spain, including Presenzano—a 1,000-MW plant near Naples (Figure 1). Following the pilot, a full program is now being rolled out that includes digital software solutions and services that will provide analysis of more than 190,000 signals and the deployment of about 800 digital asset models, aimed at improving plant operational performance, reducing unplanned failures, and enabling more efficient planned maintenance practices through predictive maintenance at the 33 plants across the country. The integration is expected to yield savings in fleet maintenance costs and increase plant productivity. The results are more competitive electricity rates in a more sustainable way.

|

|

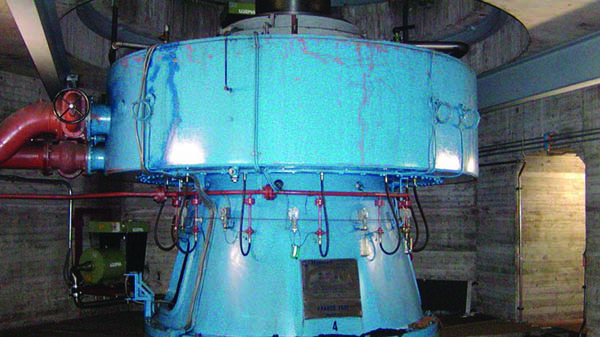

1. In the Presenzano power plant, located near Caserta, Italy, the predictive analysis carried out during routine tests was instrumental in detecting an anomaly. Higher temperatures in the steel casing of a generator weren’t caused by the machine’s malfunction but rather from the measuring chain. Courtesy: Enel Green Power |

Preserving Resources with Flow Rate Optimization

Another facility that has benefited from ABB technology is the Tombetta hydroelectric power plant. This facility is composed of seven vertical Kaplan turbines, with a total installed power of 11 MW. The turbines follow the direction of the flow stream, and each turbine has an intake tank controlled by a valve. The plant also includes several spillways, which are installed in order to discharge the excess water and prevent basin flooding.

The main scope of the system is to maintain the water level upstream by avoiding any water loss in the spillways. This is set against the challenge of maintaining the upstream water level at its maximum possible height to deliver the best possible water head and, therefore, the maximum potential energy.

The plant control system works in two different operating modes: manual or automatic. In the manual mode the operator decides the flow rate set points for each turbine according to the present situation and the operator’s experience. When set to automatic, the distributed control system (DCS) logic defines the flow rate set points by considering the turbine priorities and the maximum flow rate capacity for each turbine. In both operating modes, the first powered turbine performs the level regulation, while the rest of the turbines are used to provide the energy.

However, the dynamic response of the upstream water flow variations can be quite slow and imprecise. By using this control philosophy, the level-regulating turbine can be subject to high solicitations and high set point variations. In order to improve the control, a different system approach was implemented to optimize the load and efficiency by maintaining the optimum level and avoiding losing water through the spillways.

The solution was an optimization system that includes four key functions. The objective function (to minimize water losses), constraints (that control level and flow), input (managing available turbines and controlling water flow), and output (managing the water flow set point for each turbine). The system automatically maintains the level for all the turbines and the response to flow rate variations is faster, more precise, and more effective by avoiding high solicitations and set point variations.

Improving Excitation for Superior Reliability

Power output stability is a crucial cornerstone of any power generation plant. This has become even more true today with the growing injection of fluctuating renewable power into national grids, raising fluctuation levels and prompting stricter rules to allow connection to the grid. At the core of this is the excitation system in charge of producing the direct current that generates the magnetic field that controls the machine terminal voltage, thus, reactive power to the network. Fast and dynamic control of the magnetic field enables stable control, even in case of severe network faults.

In Paraná, southern Brazil, ABB is working with Copel’s Governador José Richa hydropower plant (Figure 2). The hydropower plant has 1,240 MW of installed power, with capacity to meet the power demands of approximately 4.5 million residents, or 40% of Paraná’s population. After 20 years of operations and a total of more than 130 million MWh generated, it was time to modernize the power plant to ensure its high performance and reliability levels continue.

|

|

2. Governador José Richa Hydroelectric power plant commenced operation in February 1999. Previously called Salto Caxias, the 1,240-MW facility is one of Copel’s most important plants. Source: Creative Commons |

New excitation systems and speed regulation have been added to four generating units at the 20-year-old plant on the Iguazu River that will boost visibility of operational data using predictive diagnostics. By upgrading the excitation system and the turbine speed regulators, and integrating them into the ABB Ability 800xA automation system, the performance and reliability of this hydroelectric power plant has been improved.

ABB’s Unitrol 6000 Static Excitation System (SES) includes a high-performance controller. Modern hardware allows the control loop to react faster to grid disturbances without disconnecting the unit from the grid. It also has two separate channels and an additional backup channel for emergency control of the generator. Each channel is designed to handle the maximum field current, enhancing reliability. The new system includes a turbine speed regulator and complies with grid code-compliance regulations.

Managing Assets Through Remote Operations

It is not always single plants that need optimization, but often a fleet of facilities, where coordination and information sharing is paramount, ever more so when hydro plants are located in remote and hard to reach locations. In Chile, for example, the interconnection of a new grid infrastructure in 2017 united the central and the northern electricity systems, and created a National Electricity System. This interconnection was a key driver for Enel Generación to modernize much of its equipment to meet the new required standard for information sharing with the National Electricity Coordinator.

As part of this modernization, Enel turned to ABB to connect 16 of its Chilean hydropower plants, situated in distant locations, to its headquarters in the capital of Santiago. Using an automation solution based on ABB Ability Symphony Plus control technology, Enel’s central control room now collects and correlates information from all plants, allowing a better coordination of the hydroelectric fleet and improved operational strategies.

The system allows data that is collected in the plants to be turned into informative insights that lead to better business decisions. The result of this approach and ABB’s remote support offering is that the location of Enel’s hydropower plants is less of an operational obstacle, with the need for engineers to make the long and complex journey out to distant sites vastly reduced. This allows Enel to redeploy its operators onto other tasks in Santiago, enabling the utility to optimize its process operations. Looking further to the future, by improving both the reliability of clean hydropower generation facilities and boosting overall grid stability to support the integration of more variable renewables, solutions like this will help bring the aims of Chile’s energy policy a step closer to realization.

Strong Future for Hydro with Better Insights

Without doubt, hydropower has a big role to play in the future in the wider energy mix. It is critical as an uninterrupted renewable source of energy and a key platform to help many energy companies and nations achieve their sustainability targets. With advanced automation and digital solutions delivering improved visibility and collaboration across operations and maintenance enabling optimized control strategies and procedures that leverage real-time data, operators can better understand, foresee, and manage risk and failure, as well as have the tools in hand to ensure optimum availability and efficiency. ■

—Pier Vittorio Rebba is technology manager, Global Product Group Power & Water, Energy Industries, with ABB.